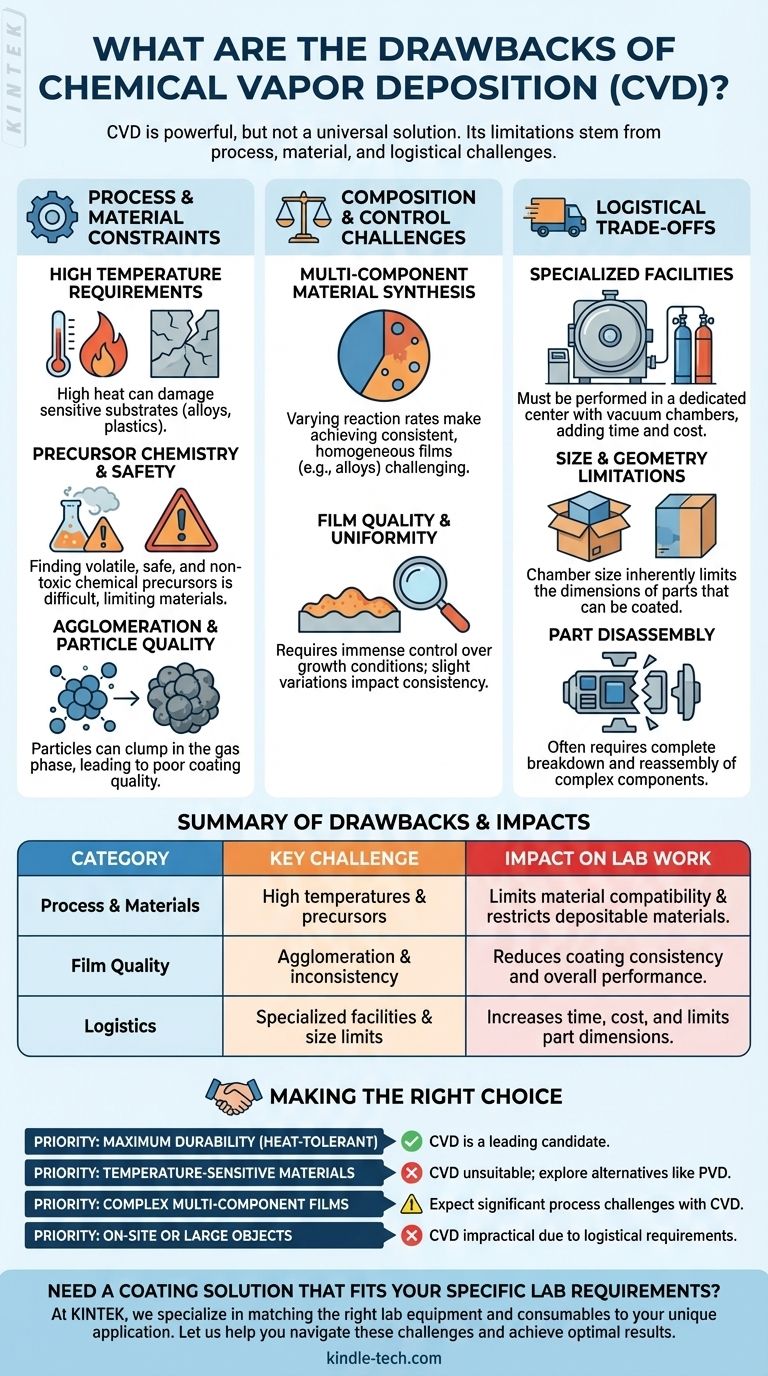

While powerful, Chemical Vapor Deposition (CVD) is not a universal solution. Its primary drawbacks stem from the high temperatures required, which can damage sensitive materials, and the complexity of finding suitable and safe chemical precursors. Additionally, it presents logistical challenges like the need for specialized vacuum chambers and often struggles to produce uniform multi-component films due to varying chemical reaction rates.

Chemical Vapor Deposition offers exceptionally high-quality and durable coatings, but this performance comes at a cost. Its primary drawbacks stem from its demanding process requirements—including high temperatures, complex precursor chemistry, and logistical inflexibility—which limit the types of materials that can be coated and the environments in which it can be performed.

Process and Material Constraints

The most significant limitations of CVD are rooted in the fundamental physics and chemistry of the process itself. These constraints dictate which materials can be used and the quality of the final product.

High Temperature Requirements

The chemical reactions that form the coating in CVD typically require high heat to initiate.

This can be a major issue when working with substrates that have a low melting point or are otherwise sensitive to thermal stress, such as certain alloys or plastics.

Precursor Chemistry and Safety

CVD relies on volatile chemical precursors—gases that contain the elements to be deposited.

Finding precursors that are sufficiently volatile, non-toxic, and non-pyrophoric (not spontaneously flammable in air) can be extremely difficult. This lack of ideal precursors can limit the materials that can be deposited via thermally activated CVD.

Agglomeration and Particle Quality

During the process, particles can agglomerate, or clump together, in the gas phase before they even reach the substrate.

This leads to the formation of hard aggregates in the final coating, which degrades the quality and makes it difficult to synthesize high-quality, uniform bulk materials.

Challenges in Composition and Control

Even when a substrate can handle the heat and suitable precursors exist, controlling the final composition and structure of the film presents another layer of difficulty.

Multi-Component Material Synthesis

Creating films with multiple elements (e.g., alloys) is particularly challenging.

Each precursor gas can have a different vapor pressure, nucleation rate, and growth rate. This variance makes it difficult to achieve a consistent, homogeneous composition throughout the film, as some elements may deposit faster than others.

Film Quality and Uniformity

Achieving a flawless, single-layer film, such as in graphene production, requires immense control over a multitude of growth conditions.

Slight variations in temperature, pressure, or gas flow within the chamber can impact the final quality, making consistent, high-end results a significant engineering challenge.

Understanding the Logistical Trade-offs

Beyond the scientific hurdles, CVD presents several practical and logistical disadvantages that can make it unsuitable for certain applications.

Requirement for Specialized Facilities

CVD is not a portable technology. It must be performed in a dedicated coating center with specialized vacuum chambers and gas handling systems.

This means parts must be transported to the facility, which adds time and cost to the manufacturing process.

Size and Geometry Limitations

The component being coated must fit inside the vacuum chamber.

This inherently limits the size of surfaces that can be treated, making it impractical for very large or oversized objects.

Necessary Part Disassembly

The "all or nothing" nature of the process means that entire components are coated.

To protect sensitive areas or to ensure the coating reaches all necessary surfaces, complex products often must be completely broken down into individual parts before the process and reassembled afterward.

Making the Right Choice for Your Goal

Ultimately, the drawbacks of CVD are trade-offs for its benefits, such as high durability and the ability to coat complex shapes. Your decision should be based on your specific project priorities.

- If your primary focus is maximum durability on a heat-tolerant substrate: CVD is a leading candidate, as its drawbacks are less relevant than its performance advantages.

- If your primary focus is coating temperature-sensitive materials (like polymers): The high heat requirements make CVD unsuitable, and you should explore lower-temperature alternatives like Physical Vapor Deposition (PVD).

- If your primary focus is synthesizing complex, multi-component alloy films: Be prepared for significant process development challenges and potential inconsistencies in composition with CVD.

- If your primary focus is on-site application or coating very large objects: The logistical requirements for a specialized vacuum facility make CVD impractical.

By understanding these limitations, you can accurately determine if CVD's high-performance results justify its significant process demands.

Summary Table:

| Drawback Category | Key Challenge | Impact on Lab Work |

|---|---|---|

| Process & Materials | High temperatures damage sensitive substrates | Limits material compatibility |

| Precursor Chemistry | Finding safe, volatile precursors is difficult | Restricts depositable materials |

| Film Quality | Agglomeration and non-uniform multi-component films | Reduces coating consistency and performance |

| Logistics | Requires specialized vacuum chambers and part disassembly | Increases time, cost, and limits part size |

Need a coating solution that fits your specific lab requirements?

At KINTEK, we understand that Chemical Vapor Deposition isn't a one-size-fits-all solution. Our experts specialize in matching the right lab equipment and consumables to your unique application—whether you need high-temperature durability, multi-component uniformity, or alternatives for sensitive materials.

Let us help you navigate these challenges and achieve optimal results. Contact our team today to discuss how KINTEK's solutions can enhance your laboratory's coating processes and efficiency.

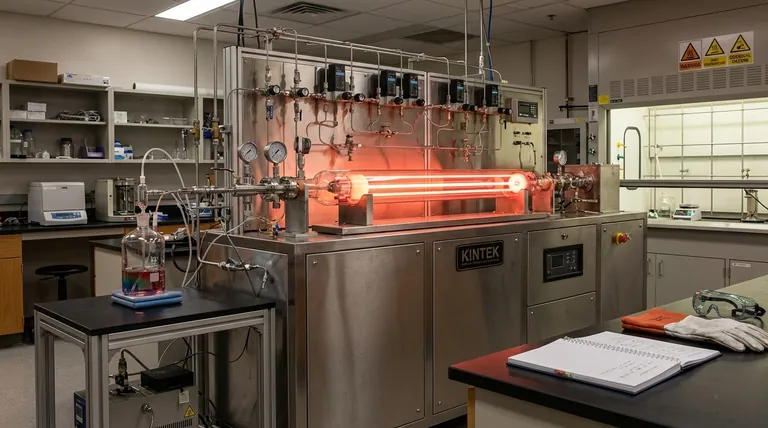

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings