In short, pyrolysis is a thermochemical process that decomposes biomass in the absence of oxygen, converting it into three distinct products: a solid (biochar), a liquid (bio-oil), and a gas (syngas). The crucial effect is not the conversion itself, but that the proportions of these three products can be precisely controlled by manipulating process conditions like temperature and heating rate.

The central takeaway is that pyrolysis is not a single, fixed process but a tunable platform. By adjusting the thermal environment, you can strategically shift the output to maximize the production of either a stable solid for carbon sequestration, a dense liquid for biofuel, or a combustible gas for immediate energy.

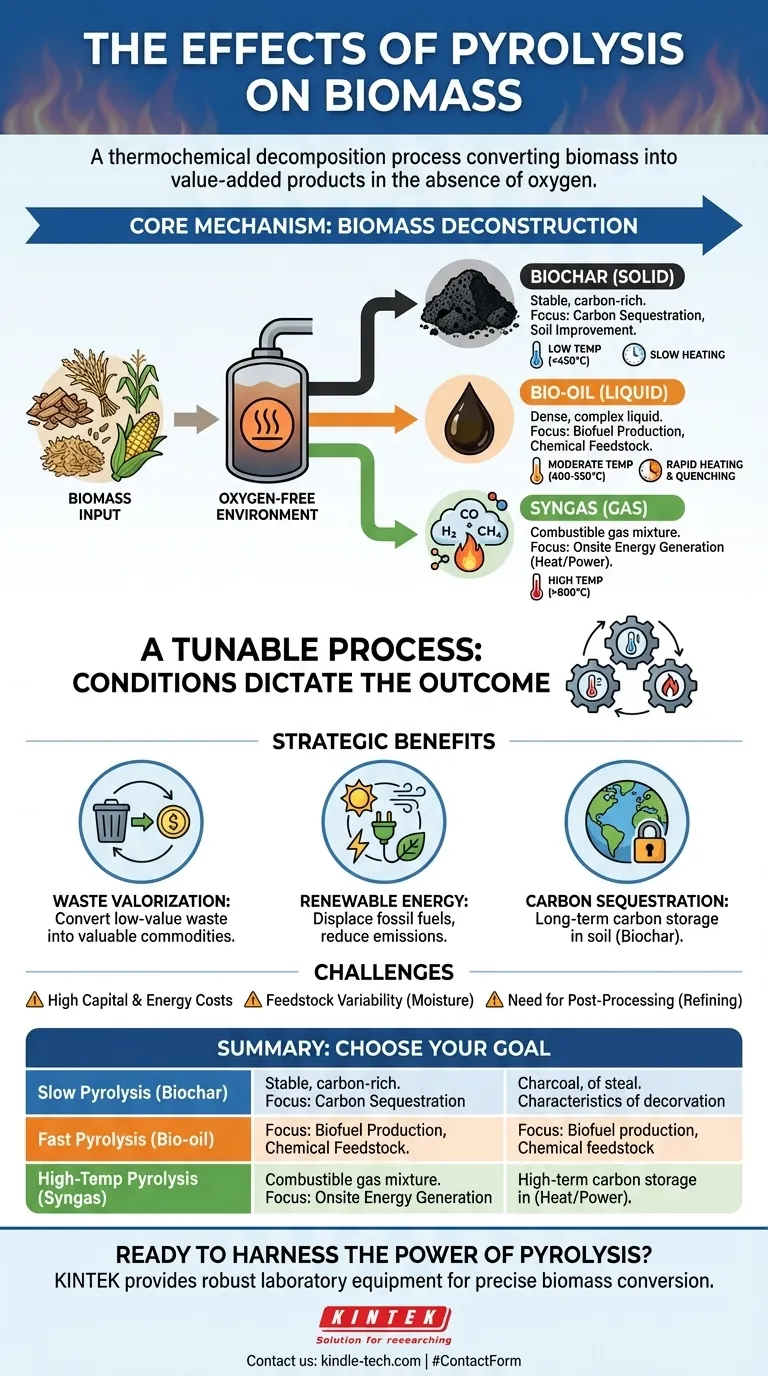

The Core Mechanism: Deconstructing Biomass Without Oxygen

What is Pyrolysis?

Pyrolysis is the thermal decomposition of organic material at elevated temperatures in an inert atmosphere. The key is the absence of oxygen, which prevents combustion.

Instead of burning, the complex polymers in biomass (like cellulose and lignin) break down, or "crack," into simpler, smaller molecules. This allows us to capture them as valuable products rather than releasing them as smoke and heat.

The Three Primary Products

The process transforms a single, often low-value input into three distinct outputs:

- Biochar: A stable, carbon-rich solid resembling charcoal.

- Bio-oil: A dense, acidic, and complex liquid mixture of oxygenated organic compounds.

- Syngas: A mixture of combustible gases, primarily hydrogen (H₂), carbon monoxide (CO), carbon dioxide (CO₂), and methane (CH₄).

How Process Conditions Dictate the Outcome

The specific effect of pyrolysis on biomass is determined entirely by the conditions you create. You can "steer" the reaction to favor one product over the others.

The Goal is Biochar (Slow Pyrolysis)

To maximize the yield of biochar, you use relatively low temperatures (below 450°C) and slow heating rates.

These conditions give the carbon atoms in the biomass time to arrange themselves into stable, aromatic structures, forming a solid char rather than breaking apart into volatile gases and liquids.

The Goal is Bio-oil (Fast Pyrolysis)

To maximize the yield of bio-oil, you use moderate temperatures (around 400-550°C) and very high heating rates. The biomass must also spend a very short time in the reactor (less than 2 seconds).

This rapid heating instantly vaporizes the organic material. These hot vapors are then quickly cooled, or "quenched," condensing them into a liquid before they have a chance to break down further into gas.

The Goal is Gas (Gasification-Pyrolysis)

To maximize the yield of syngas, you use very high temperatures (above 800°C).

At these extreme temperatures, even the intermediate bio-oil vapors are thermally cracked into the simplest, most stable gaseous molecules. This process shifts the output almost entirely to a combustible gas.

Understanding the Trade-offs and Challenges

While powerful, pyrolysis is not a perfect solution and comes with significant practical considerations.

High Capital and Energy Costs

Pyrolysis reactors require a substantial upfront investment. Furthermore, achieving and maintaining the high temperatures necessary for the process consumes a significant amount of energy, which can impact the net energy balance of the system.

Feedstock Variability

The process is versatile, capable of handling agricultural residues, wood waste, and even sewage sludge. However, the efficiency and product quality depend heavily on the feedstock's properties, especially moisture content, which must often be reduced through an energy-intensive drying step.

The Need for Post-Processing

None of the products are typically ready for immediate end-use. Bio-oil is corrosive and unstable, requiring significant refining (upgrading) before it can be used as a transportation fuel. Syngas often needs cleaning to remove tars and other impurities.

The Strategic Benefits of Pyrolysis

When managed correctly, the effects of pyrolysis offer powerful environmental and economic advantages.

Waste Valorization

The most immediate benefit is the ability to convert low-value or negative-value waste streams—such as corn stalks, sawdust, or organic municipal waste—into valuable commodities.

Renewable Energy Production

Both bio-oil and syngas are energy carriers that can displace fossil fuels for generating heat, power, or even liquid transportation fuels, thereby reducing overall greenhouse gas emissions.

Carbon Sequestration

Biochar is a highly stable form of carbon. When added to soil, it can lock that carbon away for hundreds or even thousands of years, effectively removing it from the atmosphere. This makes slow pyrolysis a potent carbon-negative technology.

Making the Right Choice for Your Goal

Your strategy for using pyrolysis should be dictated entirely by your primary objective.

- If your primary focus is carbon sequestration and soil improvement: You should pursue slow pyrolysis at lower temperatures to maximize the production of stable biochar.

- If your primary focus is producing a liquid biofuel or chemical feedstock: You must implement fast pyrolysis with rapid heating and quenching to maximize the yield of bio-oil.

- If your primary focus is generating immediate onsite energy for heat or power: You should use high-temperature pyrolysis to maximize the conversion of biomass into combustible syngas.

Ultimately, understanding that pyrolysis is a controllable process is the key to unlocking its potential for waste management, energy production, and climate mitigation.

Summary Table:

| Process Condition | Primary Goal | Main Product | Key Characteristics |

|---|---|---|---|

| Slow Pyrolysis (<450°C, slow heating) | Carbon Sequestration / Soil Improvement | Biochar | Stable, solid carbon for long-term storage |

| Fast Pyrolysis (400-550°C, rapid heating) | Liquid Biofuel Production | Bio-oil | Dense liquid requiring further refining |

| High-Temp Pyrolysis (>800°C) | Onsite Energy Generation | Syngas | Combustible gas mixture (H₂, CO, CH₄) |

Ready to harness the power of pyrolysis for your biomass conversion needs?

KINTEK specializes in providing robust laboratory equipment for pyrolysis research and development. Whether your goal is to optimize biochar production for carbon sequestration, refine bio-oil for biofuels, or maximize syngas yield for energy, our solutions are designed to deliver precise control over temperature and process conditions.

Contact us today using the form below to discuss how our expertise can help you achieve your specific biomass conversion objectives. Let's build a sustainable future together.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What biomass is used in pyrolysis? Selecting the Optimal Feedstock for Your Goals

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products