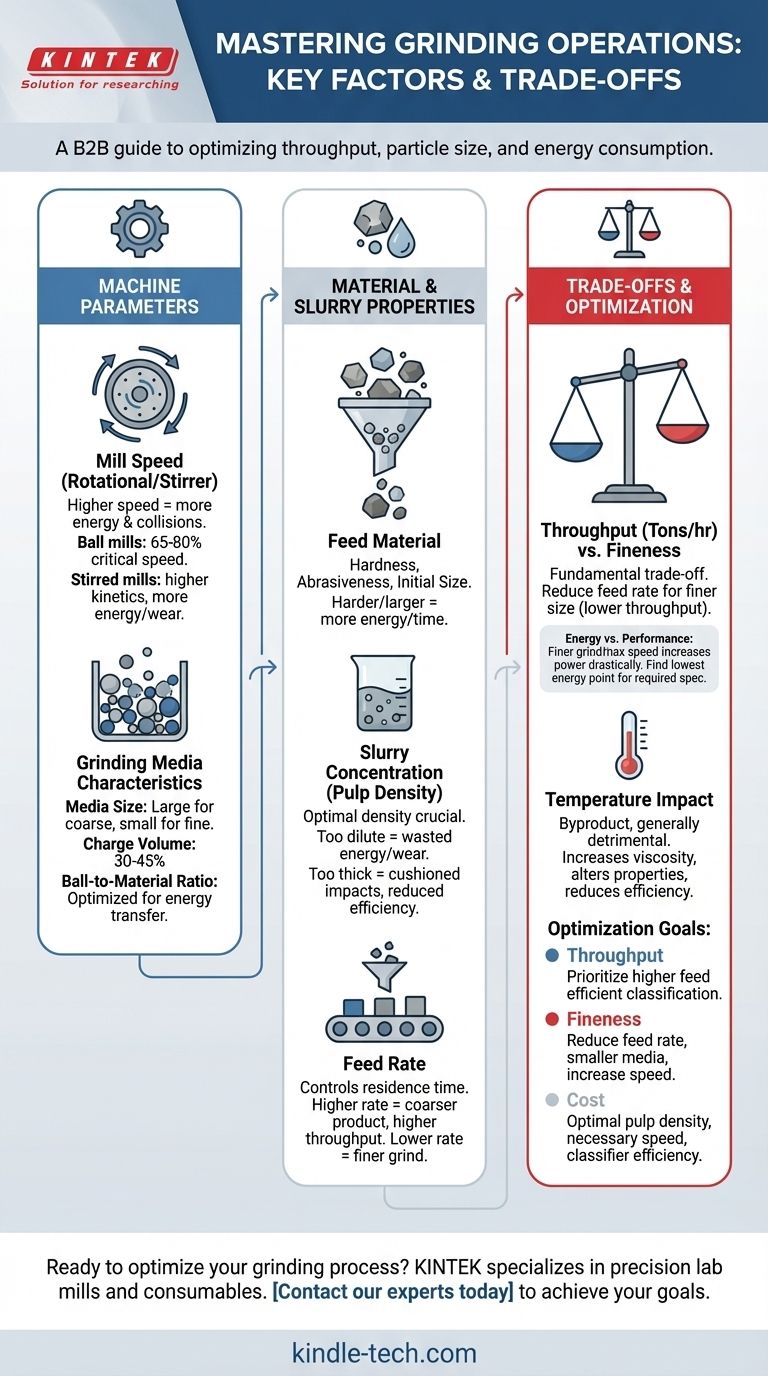

In any grinding operation, performance is dictated by a specific set of interconnected variables. The outcome is a direct result of the equipment's configuration, the properties of the material being processed, and the parameters chosen by the operator. Key factors include the rotational speed of the mill, the characteristics of the grinding media, the rate at which material is fed, and the density of the material slurry.

The central challenge of grinding is not merely identifying these factors, but understanding their interplay. Optimizing a grinding circuit is a balancing act between three competing goals: maximizing throughput, achieving the target particle size, and minimizing energy consumption.

Core Machine Parameters

The physical setup and operating speed of the grinding mill are the foundational levers for controlling the process.

Mill Speed (Rotational or Stirrer)

Mill speed directly determines the amount of energy imparted to the grinding media and, consequently, to the material. A higher speed results in more forceful and frequent collisions or shearing actions.

For ball mills, speed is often discussed in relation to "critical speed"—the theoretical speed at which media would centrifuge and cling to the mill liner, causing grinding to cease. Most mills operate between 65-80% of critical speed.

In stirred media mills, a higher stirrer speed generally enhances grinding kinetics and produces a finer final particle size, but at the cost of significantly higher energy consumption and wear.

Grinding Media Characteristics

The grinding media (e.g., steel balls, ceramic beads) are the tools doing the work inside the mill. Their properties are critical.

- Size: Larger media are more effective at breaking large feed particles, while smaller media are more efficient for producing a very fine product.

- Charge Volume: The "ball charge" or amount of media in the mill (typically 30-45% of the volume) dictates the number of grinding events.

- Ball-to-Material Ratio: The ratio of the mass of the media to the mass of the material being ground must be optimized for efficient energy transfer.

Material and Slurry Properties

The characteristics of the substance entering the mill are just as important as the machine itself.

Feed Material Characteristics

The inherent properties of the feed material set the baseline for the energy and time required. Key factors include the material's hardness, abrasiveness, and initial particle size.

Harder materials require more energy to fracture. A larger initial particle size will require a longer residence time in the mill to be ground down to the target fineness.

Slurry Concentration (Pulp Density)

In wet grinding, the ratio of solids to water in the slurry is a critical factor. There is an optimal density for every operation.

If the slurry is too dilute (too much water), the grinding media will primarily strike each other, wasting energy and causing excessive media and liner wear.

If the slurry is too thick, the viscosity will cushion the impacts of the media, drastically reducing grinding efficiency.

Feed Rate

The rate at which new material is fed into the mill controls the residence time. A higher feed rate means material spends less time inside the mill, resulting in a coarser final product but higher throughput. Conversely, a lower feed rate increases residence time, leading to a finer grind.

Understanding the Trade-offs

Effective grinding is about managing compromises. Adjusting one variable will always have consequences for others.

Throughput vs. Fineness

This is the most fundamental trade-off. To achieve a finer particle size, you must typically reduce the feed rate, which lowers the overall throughput (tons per hour) of the circuit. Increasing mill speed can compensate slightly, but this comes at a cost.

Energy Consumption vs. Performance

Grinding is one of the most energy-intensive processes in industry. Pushing for the absolute finest grind or the maximum possible speed will dramatically increase power consumption. True optimization involves finding the lowest energy point that still achieves the required product specification, not the finest possible one.

The Impact of Temperature

Grinding is a mechanical process that generates significant heat. Unlike in chemical processes, higher temperature is generally detrimental. It can increase slurry viscosity, alter material properties, and promote the agglomeration of fine particles, all of which reduce grinding efficiency. Temperature is a byproduct to be managed, not a lever for improvement.

Optimizing for Your Primary Goal

The "correct" settings depend entirely on what you are trying to achieve. Use these principles to guide your operational decisions.

- If your primary focus is maximizing throughput (tons per hour): Prioritize a higher feed rate and ensure your classification system is efficiently removing correctly-sized product to avoid unnecessary re-grinding.

- If your primary focus is achieving a very fine particle size: Reduce the feed rate to increase residence time, use smaller grinding media for better fine-grinding efficiency, and potentially increase mill speed.

- If your primary focus is minimizing operational cost (energy and wear): Operate at the optimal pulp density, avoid running the mill at speeds beyond what is necessary, and focus on classifier efficiency to prevent wasting energy.

Mastering these variables transforms grinding from a brute-force process into a precisely controlled engineering discipline.

Summary Table:

| Factor Category | Key Variables | Primary Impact |

|---|---|---|

| Machine Parameters | Mill Speed, Media Size & Charge | Energy input and grinding efficiency |

| Material Properties | Feed Hardness, Initial Size | Baseline energy and time required |

| Process Parameters | Feed Rate, Slurry Density (Pulp Density) | Throughput and final particle size |

| Operational Goals | Throughput vs. Fineness vs. Cost | Dictates the optimal balance of variables |

Ready to optimize your grinding process? The right lab equipment is key to balancing throughput, particle size, and energy consumption. KINTEK specializes in precision lab mills and consumables to help you achieve your specific goals. Contact our experts today to discuss your application and find the perfect solution for your laboratory needs.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Mini Planetary Ball Mill Machine for Laboratory Milling

People Also Ask

- What safety checks should you do before using a grinder? Master the 3-Pillar Inspection for Accident-Free Operation

- What is the function of a Wiley grinding mill in the processing of elephant grass? Optimize Your Chemical Analysis

- What are mill balls made of? Choose the Right Material for Efficient Grinding

- What role does a ball mill play in the preparation of Ti-Si-C reaction powder mixtures? Unlock SHS Efficiency

- Why are alumina grinding balls preferred for Magnesium Aluminate Spinel? Achieve Pure, High-Performance Ceramic Milling

- What is the impact of speed on ball mill performance? Optimize Grinding Efficiency & Particle Size

- What does a colloid mill do? Achieve Superior Emulsions and Fine Dispersions

- Is there a machine that makes wood pellets? The Pellet Mill Explained for DIY and Industrial Use