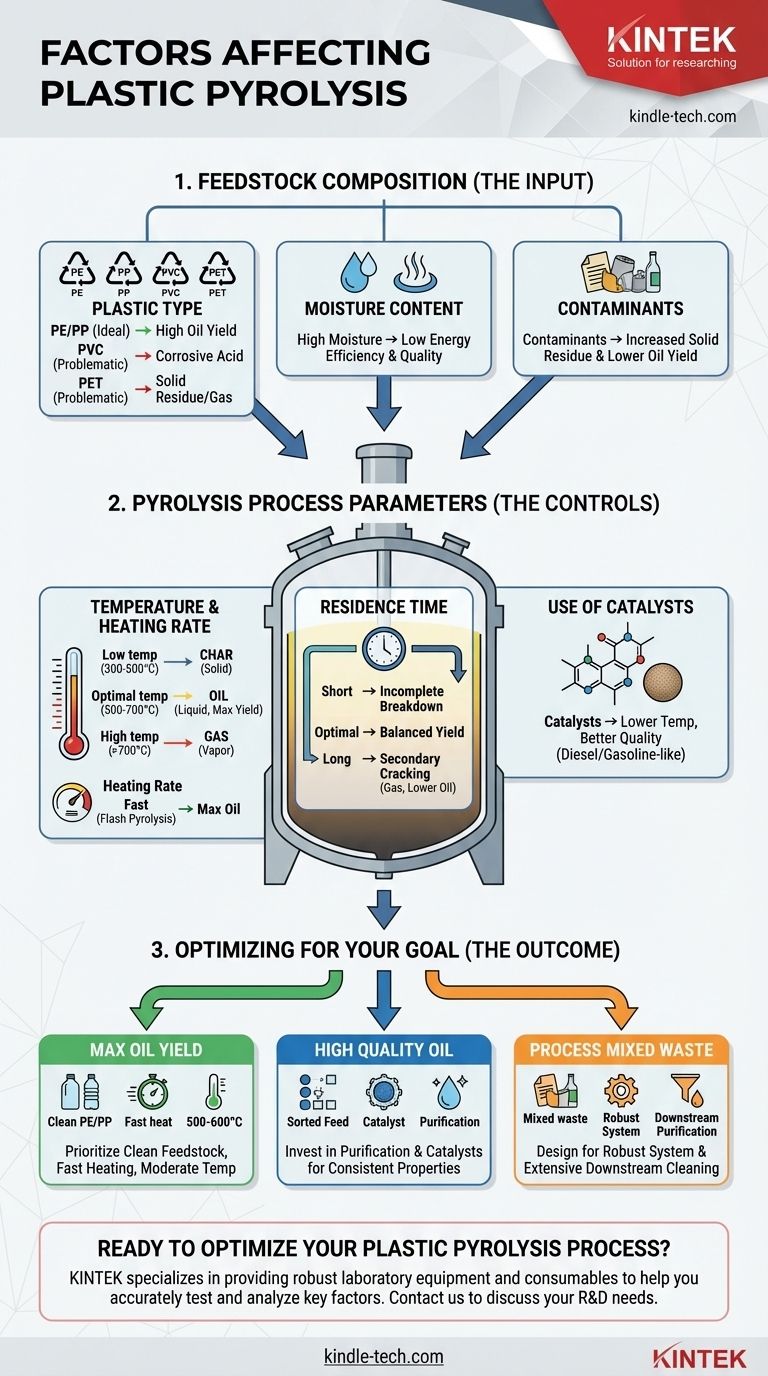

The primary factors affecting plastic pyrolysis are the composition of the plastic waste and the operational parameters of the reactor. The type of plastic, its moisture level, and the presence of non-plastic contaminants fundamentally dictate the potential output, while process variables like temperature, heating rate, and the use of catalysts determine the final yield and quality of the resulting oil and other products.

The core challenge in plastic pyrolysis is managing variability. While optimizing reactor conditions is a technical exercise, the single greatest influence on the process's success and economic viability is the quality and consistency of the incoming plastic feedstock.

The Critical Role of Feedstock Composition

The material you put into the reactor is the single most important variable. Inconsistent or contaminated feedstock is the most common point of failure for pyrolysis operations.

Type of Plastic Polymer

Different plastics are made of different chemical building blocks, which break down into different products. Polyolefins like Polyethylene (PE) and Polypropylene (PP) are ideal, yielding high quantities of valuable hydrocarbon oils.

Conversely, plastics like Polyvinyl Chloride (PVC) are highly problematic, releasing corrosive hydrochloric acid during heating, which can damage equipment. Polyethylene terephthalate (PET) also behaves differently, often producing more solid residue and gases than liquid oil.

Moisture Content

Any water present in the feedstock must be evaporated before the plastic can break down. This process consumes a significant amount of energy, reducing the overall energy efficiency of the system.

High moisture content can also lead to the formation of emulsions and increase the oxygen content in the pyrolysis oil, lowering its quality and fuel value.

Non-Plastic Contaminants

Contaminants like paper, wood, food waste, metal, and glass do not convert into oil. Instead, they typically increase the amount of solid residue (char or ash) and gas produced, which lowers the final oil yield.

These materials can also introduce elements like sulfur or nitrogen, leading to lower-quality oil that may require more intensive downstream purification.

Key Pyrolysis Process Parameters

Once the feedstock is chosen, the reactor's operating conditions are used to control the chemical reactions and steer the output toward the desired products.

Temperature and Heating Rate

Temperature is arguably the most critical process parameter. Lower temperatures (300-500°C) and slow heating rates tend to favor the production of solid char.

Higher temperatures (500-700°C) and rapid heating rates ("flash pyrolysis") maximize the conversion of plastic into the vapor phase, which, after cooling, results in the highest possible liquid oil yield. Very high temperatures (>700°C) favor the production of gas.

Residence Time

This refers to the amount of time the plastic material spends inside the hot zone of the reactor. A longer residence time can allow for more complete breakdown of larger polymer chains.

However, if the residence time is too long, it can lead to secondary cracking of the valuable oil vapors into less desirable, non-condensable gases, thereby reducing the final liquid yield.

Use of Catalysts

Catalysts can be introduced into the process to improve its efficiency and selectively control the output. They can lower the required reaction temperature, saving energy.

More importantly, specific catalysts can "steer" the chemical reactions to produce a narrower range of hydrocarbons, resulting in a pyrolysis oil with properties closer to conventional fuels like diesel or gasoline, reducing the need for extensive upgrading.

Understanding the Trade-offs and Challenges

Successfully implementing plastic pyrolysis requires navigating a series of technical and economic compromises.

The Feedstock vs. Process Cost Dilemma

There is a fundamental trade-off between investing in feedstock preparation versus a more complex process. You can spend more money on sorting and cleaning plastic waste to get a pure input, which simplifies the pyrolysis process.

Alternatively, you can build a more robust and expensive reactor and purification system designed to handle mixed, contaminated waste. Neither approach is universally superior; the choice depends on local waste availability and economic goals.

The Problem of Persistent Contaminants

Even with sorting, some contaminants are difficult to remove. Additives, dyes, and flame retardants within the plastic matrix itself can end up in the pyrolysis oil or char, potentially creating hazardous byproducts that require special handling and disposal.

Inconsistent Output Quality

The biggest commercial challenge is producing a consistent product from an inconsistent input. Variations in feedstock mean the resulting pyrolysis oil can differ in viscosity, density, and chemical composition from one batch to the next, making it difficult to sell to refineries or chemical plants that require a reliable, standardized product.

Making the Right Choice for Your Goal

Your operational strategy should be dictated by your primary objective.

- If your primary focus is maximizing liquid oil yield: Prioritize clean, sorted feedstock consisting of PE and PP, and operate with a fast heating rate at a moderate-to-high temperature (around 500-600°C).

- If your primary focus is producing high-quality, consistent oil: Invest heavily in feedstock purification to remove contaminants and consider using specific catalysts to control the oil's chemical properties.

- If your primary focus is processing mixed waste with minimal pre-treatment: You must design or select a robust pyrolysis system capable of handling contaminants and plan for significant downstream oil purification to create a marketable product.

Ultimately, controlling the factors of plastic pyrolysis is a balance between managing the quality of your input material and fine-tuning your process conditions to achieve a specific outcome.

Summary Table:

| Factor | Key Influence on Pyrolysis |

|---|---|

| Plastic Type (Polymer) | Determines product distribution (oil, gas, char). PE/PP ideal; PVC/PET problematic. |

| Temperature | Critical for product yield. Low temp = more char; High temp (500-700°C) = max oil. |

| Catalysts | Lowers reaction temperature and improves oil quality, making it closer to conventional fuel. |

| Moisture & Contaminants | Reduces energy efficiency and oil yield, increases residue, and lowers oil quality. |

Ready to optimize your plastic pyrolysis process?

KINTEK specializes in providing robust laboratory equipment and consumables to help you accurately test and analyze the key factors affecting your pyrolysis output. Whether you are researching feedstock suitability, optimizing temperature parameters, or testing catalysts, our reliable tools are designed for your laboratory's needs.

Contact us today using the form below to discuss how we can support your pyrolysis R&D and help you achieve a more efficient and profitable process.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas