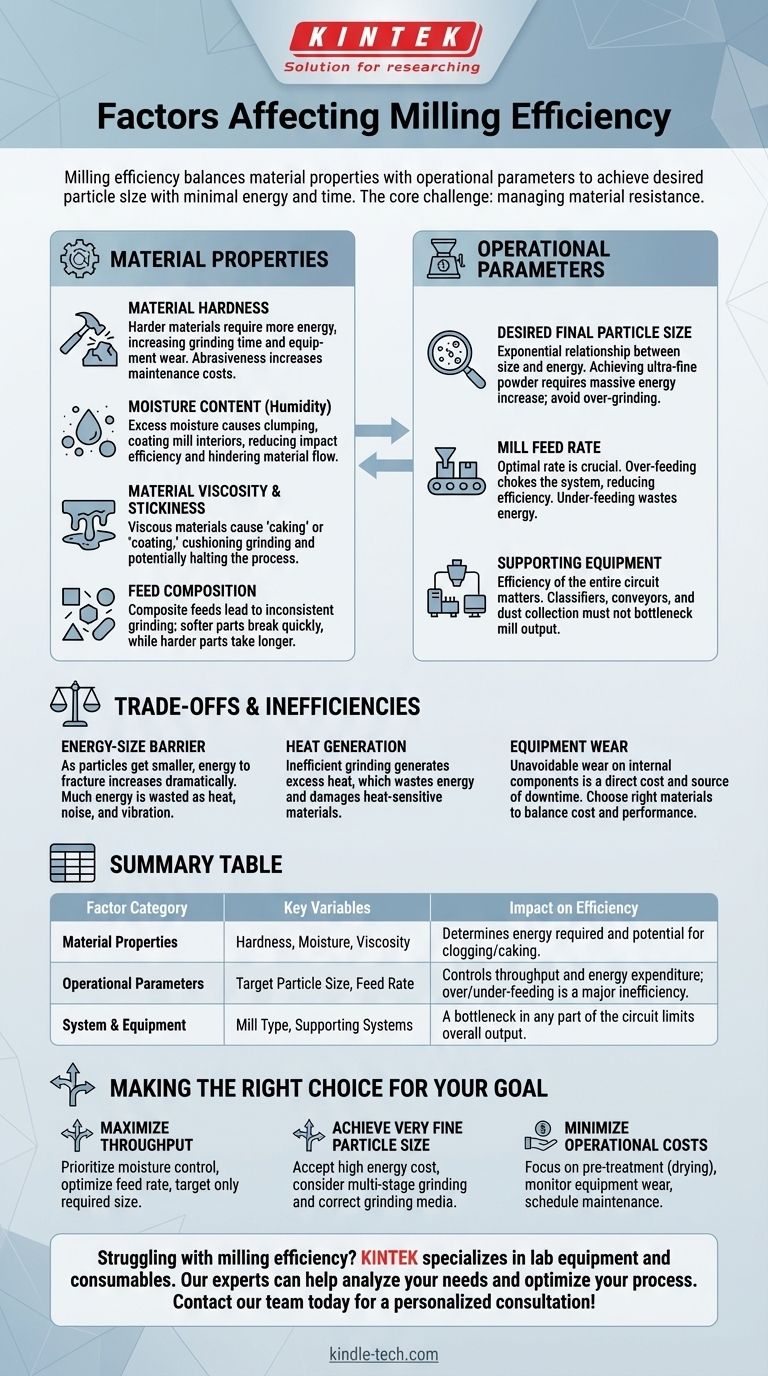

In short, milling efficiency is determined by a complex interplay between the intrinsic properties of the material being processed and the operational parameters of the mill itself. Key factors include the material’s hardness, moisture content, and viscosity, as well as the target final particle size.

The core challenge in milling is not simply size reduction, but achieving the desired particle size with the minimum expenditure of energy and time. True efficiency comes from understanding that the material's resistance to being broken down is the primary variable you must manage.

The Influence of Material Properties

The physical and chemical nature of the material you are grinding is the single most significant factor in any milling operation. It dictates the energy required, the potential throughput, and the wear on your equipment.

Material Hardness

Harder materials fundamentally require more energy to fracture. This directly translates to longer grinding times or higher power consumption to achieve the desired particle size. Abrasive materials also accelerate the wear of mill liners and grinding media, increasing maintenance costs and downtime.

Moisture Content (Humidity)

Excess moisture can cause materials to become sticky and agglomerate. Instead of fracturing, particles clump together, coating the inside of the mill and the grinding media. This severely reduces the efficiency of impacts and hinders the flow of material through the system.

Material Viscosity and Stickiness

Separate from moisture, some materials are naturally viscous or sticky. This causes significant "caking" or "coating" issues within the mill, which cushions the grinding action and can bring the entire process to a halt if not properly managed.

Feed Composition

If the feed material is a composite of multiple substances with different hardness or properties, it can lead to inconsistent grinding. Softer components will break down quickly, while harder components require more time, making it difficult to achieve a uniform final product.

The Role of Operational Parameters

How you configure and run the mill is the second half of the efficiency equation. Matching the operation to the material is critical for success.

Desired Final Particle Size

There is an exponential relationship between particle size and energy input. Grinding a coarse material is relatively energy-efficient, but achieving an ultra-fine powder requires a disproportionately massive increase in energy and time. Specifying a finer particle size than necessary is a common source of inefficiency.

Mill Feed Rate

The rate at which you introduce material into the mill is crucial. Over-feeding can choke the system, cushioning the grinding action and drastically lowering efficiency. Under-feeding wastes energy by running the mill without doing productive work. Finding the optimal feed rate is key.

Supporting Equipment

The efficiency of the entire circuit, not just the mill, matters. This includes the performance of classifiers, conveyors, and dust collection systems. A bottleneck in any of these supporting measures will directly limit the output of the mill itself.

Understanding the Trade-offs and Inefficiencies

Perfect efficiency is impossible. Recognizing the inherent trade-offs helps you diagnose problems and set realistic performance goals.

The Energy-Size Barrier

As particles become smaller, the energy required to create new fractures increases dramatically. Much of the energy input is inevitably converted into non-productive heat, noise, and vibration rather than useful size reduction. This is a fundamental physical limitation.

Heat Generation

Inefficient grinding generates excess heat. This not only represents wasted energy but can also negatively affect heat-sensitive materials, potentially causing chemical changes or melting, which further complicates the milling process.

Equipment Wear

An unavoidable consequence of milling is the wear and tear on internal components. This is a direct operational cost and a source of downtime. Choosing the right materials for mill liners and grinding media is a critical decision to balance cost and performance.

Making the Right Choice for Your Goal

To optimize your process, you must first define your primary objective. Different goals require focusing on different factors.

- If your primary focus is maximizing throughput: Prioritize controlling moisture content and optimizing the feed rate to avoid choking the mill. Do not over-grind; target only the required particle size.

- If your primary focus is achieving a very fine particle size: Accept that this is an energy-intensive goal. Consider multi-stage grinding and ensure you are using the correct size and type of grinding media for the final stage.

- If your primary focus is minimizing operational costs: Pay close attention to material pre-treatment, such as drying. Regularly monitor equipment for wear to prevent catastrophic failure and schedule preventative maintenance.

Ultimately, mastering milling efficiency means treating the process as a complete system where the material, machine, and operational settings must work in harmony.

Summary Table:

| Factor Category | Key Variables | Impact on Efficiency |

|---|---|---|

| Material Properties | Hardness, Moisture, Viscosity | Determines energy required and potential for clogging/caking. |

| Operational Parameters | Target Particle Size, Feed Rate | Controls throughput and energy expenditure; over/under-feeding is a major inefficiency. |

| System & Equipment | Mill Type, Supporting Systems (e.g., classifiers) | A bottleneck in any part of the circuit limits overall output. |

Struggling with low throughput, high energy costs, or inconsistent particle size? KINTEK specializes in lab equipment and consumables, serving laboratory milling needs. Our experts can help you analyze your specific material and process goals to select the ideal mill and optimize your operational parameters for peak efficiency. Contact our team today for a personalized consultation and see how we can enhance your grinding process!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes

- What is the ball mill based on the principle of? Impact and Attrition for Efficient Grinding

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results