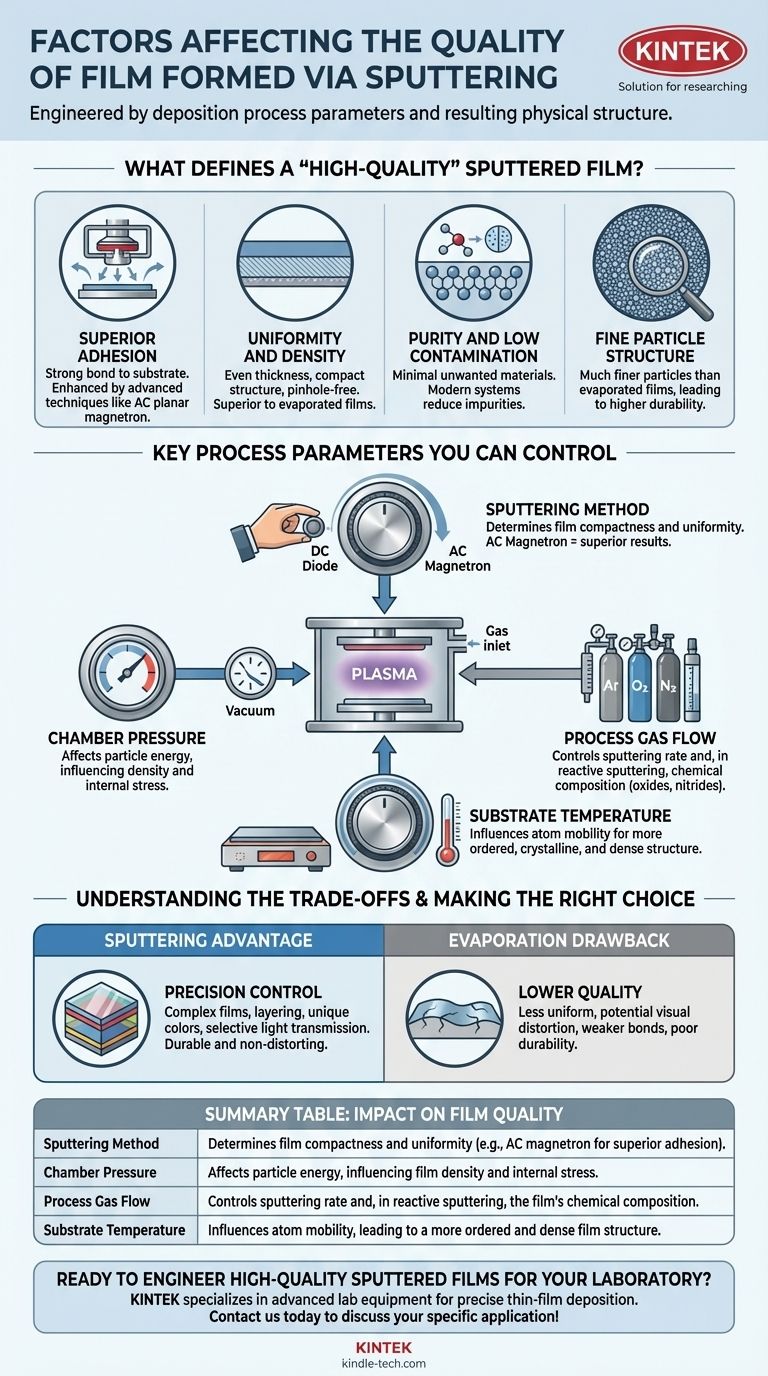

The quality of a film formed via sputtering is determined by the deposition process parameters and the resulting physical structure of the film. Key factors include the sputtering method itself, chamber pressure, process gas flow, and substrate temperature, which collectively influence the film's density, uniformity, purity, and adhesion to the substrate.

The core principle is that sputtering offers a high degree of control over the atomic-level assembly of a film. Unlike simpler methods, it allows for the creation of dense, uniform, and highly adherent layers by managing the energy and environment in which particles deposit onto a surface.

What Defines a "High-Quality" Sputtered Film?

Before adjusting process parameters, it's essential to understand the target characteristics. High-quality sputtered films are defined by a few key attributes that set them apart from films made by other methods, such as vacuum evaporation.

Superior Adhesion

A critical quality indicator is how well the film bonds to the underlying material, or substrate.

Advanced techniques like AC planar magnetron sputtering are specifically designed to enhance this bond, creating a more durable and reliable coating.

Uniformity and Density

Quality films have an even thickness and a compact structure across the entire surface.

Sputtering produces films that are free of pinholes and other structural defects, ensuring consistent performance. This is a significant advantage over vacuum-evaporated films, which tend to be less even.

Purity and Low Contamination

The final film should consist only of the intended material.

Modern sputtering systems excel at reducing unwanted contamination during the deposition process, resulting in higher purity films compared to older or simpler techniques.

Fine Particle Structure

The microscopic structure of the film is fundamental to its quality.

Sputtered films are composed of much finer metal particles than evaporated films. This fine-grained structure is directly responsible for their higher durability and superior performance.

Key Process Parameters You Can Control

The final quality of the film is not accidental; it is engineered by carefully controlling the variables of the sputtering process.

Sputtering Method

The technology you use is a primary factor. For example, using an AC planar magnetron sputtering system inherently produces more compact and uniform films than a basic DC diode system.

Chamber Pressure

The pressure inside the deposition chamber affects how sputtered atoms travel from the target to the substrate.

Adjusting this parameter can alter the energy of the depositing particles, which in turn influences the film's density and internal stress.

Process Gas Flow

The flow rate of the inert gas (typically Argon) used to create the plasma directly impacts the sputtering rate.

In reactive sputtering, the controlled introduction of gases like oxygen or nitrogen is used to intentionally form oxide or nitride films, fundamentally changing the film's chemical and optical properties.

Substrate Temperature

The temperature of the substrate during deposition influences how atoms arrange themselves once they land on the surface.

Higher temperatures can increase atom mobility, which can help form a more ordered, crystalline, and dense film structure.

Understanding the Trade-offs: Sputtering vs. Evaporation

To fully appreciate the factors affecting sputtered film quality, it's useful to compare it directly with a common alternative, thermal vacuum evaporation.

The Advantage of Sputtering

Sputtering's main advantage is control. The process allows for the creation of complex films by layering different metals and metal oxides with precision.

This control enables the engineering of films with unique colors and selective light transmission, which is not possible with less-refined methods. The resulting films are durable and do not distort vision.

The Drawback of Evaporation

Vacuum evaporated films are generally considered lower quality.

They suffer from a less uniform structure, which can cause visual distortion, and their weaker molecular bonds lead to poor durability.

Making the Right Choice for Your Goal

Controlling film quality is about aligning process parameters with your desired outcome. Use these guidelines to prioritize your efforts.

- If your primary focus is durability and adhesion: Concentrate on creating a dense, pinhole-free structure by optimizing chamber pressure and utilizing an advanced method like AC magnetron sputtering.

- If your primary focus is specific optical properties: Carefully manage the reactive gas flow and the layering of different materials to achieve the precise refractive index and selective transmission you require.

- If your primary focus is purity and uniformity: Ensure you are using a high-purity target material and a sputtering technique known for its even deposition across large surface areas.

Ultimately, controlling these factors empowers you to engineer sputtered films with precisely the characteristics your application demands.

Summary Table:

| Factor | Impact on Film Quality |

|---|---|

| Sputtering Method | Determines film compactness and uniformity (e.g., AC magnetron for superior adhesion). |

| Chamber Pressure | Affects particle energy, influencing film density and internal stress. |

| Process Gas Flow | Controls sputtering rate and, in reactive sputtering, the film's chemical composition. |

| Substrate Temperature | Influences atom mobility, leading to a more ordered and dense film structure. |

Ready to engineer high-quality sputtered films for your laboratory?

KINTEK specializes in advanced lab equipment and consumables for precise thin-film deposition. Our expertise in sputtering technology can help you achieve the durable, uniform, and pure coatings your research or production demands.

Contact us today to discuss your specific application and discover how our solutions can enhance your results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition