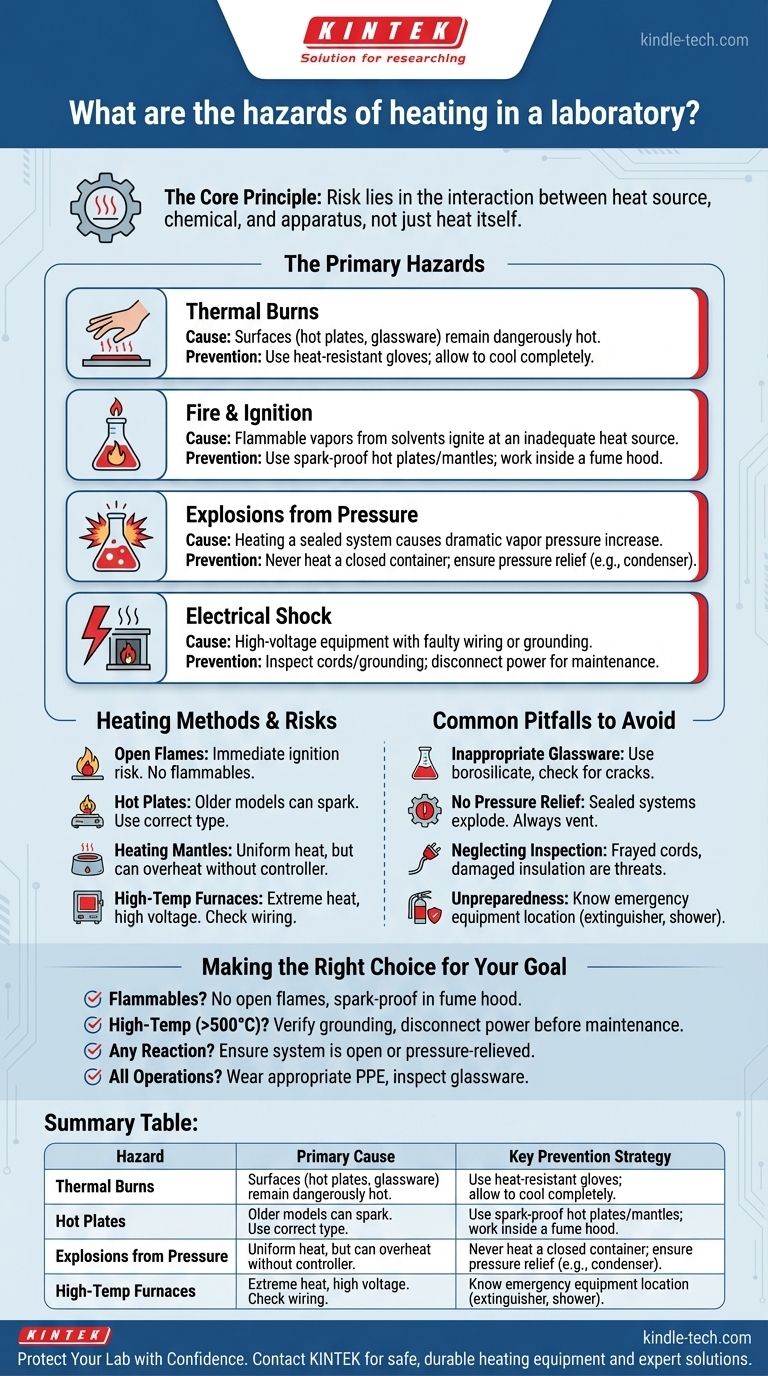

Laboratory heating is a fundamental procedure that introduces significant, often underestimated, hazards. The most immediate dangers are severe thermal burns from hot surfaces, fires from the ignition of flammable materials, and violent explosions from uncontrolled pressure buildup in sealed systems. High-power equipment like furnaces also adds the severe risk of electrical shock and electrocution.

The core principle of heating safety is recognizing that the primary hazard is rarely just the heat itself. The true risk lies in the interaction between the heat source, the chemical substances being heated, and the apparatus containing them.

The Primary Hazards: A Deeper Look

Understanding the specific nature of each hazard is the first step toward mitigating it. Each risk has a distinct cause and requires a targeted prevention strategy.

Thermal Burns

This is the most direct danger. Surfaces on hot plates, furnaces, and even glassware can remain dangerously hot long after the power has been turned off.

These burns can be severe, and the lack of a visual cue for a hot-but-no-longer-glowing surface makes accidental contact a common injury.

Fire and Ignition

Many laboratory solvents are highly flammable, and their vapors can easily be ignited by an inadequate heat source.

A common mistake is underestimating vapor travel. Heavier-than-air vapors from a flask can flow across a lab bench to an ignition source, such as the sparking motor of an old hot plate or an open flame.

Explosions from Pressure

Heating a liquid in a sealed or closed container is one of the most dangerous laboratory mistakes. The liquid's vapor pressure increases dramatically with temperature, which can cause glassware to fail catastrophically.

This results in a violent explosion of hot, often corrosive or flammable, material and glass shards.

Electrical Shock

High-temperature equipment, such as a furnace operating above 500°C, requires high voltage and current to function.

This creates a serious risk of electrocution if wiring is frayed, grounding is improper, or safety interlocks are bypassed. Contact with exposed furnace elements is exceptionally dangerous due to the high current.

Matching the Hazard to the Heating Method

Different heating instruments present different risk profiles. Choosing the right tool for the job is a critical safety decision.

Open Flames (Bunsen Burners)

The ignition risk is obvious and immediate. Open flames should never be used to heat flammable organic liquids. They also create a localized "hot spot" on glassware, increasing the risk of thermal shock and breakage.

Hot Plates

Hot plates are ubiquitous, but older or cheaper models may contain sparking motors that can ignite flammable vapors. The risk of fire is significant if the wrong type of hot plate is used for volatile substances.

Heating Mantles

These offer more uniform heating for round-bottom flasks, reducing the risk of thermal shock. However, without a temperature controller, a mantle can easily overheat, potentially causing a substance to decompose or ignite.

High-Temperature Furnaces

These units combine extreme heat with high-voltage electricity. The risk of severe burns is high, and electrical hazards are a primary concern. Furnace elements are fragile, expensive, and operate at dangerous amperages.

Common Pitfalls to Avoid

Most heating-related incidents stem from a small number of recurring and preventable errors. Awareness is the best defense.

Using Inappropriate Glassware

Not all glass is created equal. Standard soda-lime glass will shatter under the thermal stress of rapid heating. Always use borosilicate glassware (e.g., Pyrex or Kimax) that is free of cracks or chips.

Failing to Ensure Pressure Relief

Never heat a system that is completely sealed from the atmosphere. A reaction or distillation setup must have an outlet, such as a condenser open to the air, to safely vent any pressure buildup.

Neglecting Equipment Inspection

Frayed power cords, malfunctioning temperature controllers, and damaged furnace insulation are direct threats. A brief visual inspection before each use is a simple but effective safety measure.

Being Unprepared for Failure

Accidents can happen even with proper precautions. Not knowing the location of the nearest fire extinguisher, safety shower, or fire blanket can turn a minor incident into a major catastrophe.

Making the Right Choice for Your Goal

Your safety strategy should be dictated by the specific materials and apparatus you are using.

- If your primary focus is working with flammable liquids: Never use an open flame. Use a heating mantle or a spark-proof hot plate, and perform the work inside a certified chemical fume hood.

- If your primary focus is high-temperature work (>500°C): Always verify proper electrical grounding, inspect power cords, and completely disconnect power before opening the furnace door or performing maintenance.

- If your primary focus is heating any reaction: Always ensure the system is open to the atmosphere or protected by a pressure-relief device to prevent a catastrophic explosion.

- For all heating operations: Wear appropriate personal protective equipment (PPE), including safety glasses and heat-resistant gloves, and confirm that glassware is free of any defects.

A proactive assessment of your specific materials and equipment is the cornerstone of safe laboratory heating.

Summary Table:

| Hazard | Primary Cause | Key Prevention Strategy |

|---|---|---|

| Thermal Burns | Contact with hot surfaces (hot plates, glassware) | Use heat-resistant gloves; allow equipment to cool completely. |

| Fire & Ignition | Flammable solvent vapors meeting an ignition source | Use spark-proof hot plates/mantles; work inside a fume hood. |

| Explosion | Pressure buildup in a sealed system | Never heat a closed container; ensure proper pressure relief. |

| Electrical Shock | Faulty wiring in high-power equipment (furnaces) | Inspect cords and grounding before each use; disconnect power for maintenance. |

Protect Your Lab and Your Team with Confidence

Navigating the risks of laboratory heating requires reliable equipment and expert support. KINTEK specializes in providing safe, durable lab equipment and consumables—from spark-proof hot plates to high-temperature furnaces—specifically designed to meet the rigorous demands of laboratory environments.

Our team understands your safety challenges. We don't just sell equipment; we provide solutions that help you prevent accidents and ensure compliance. Let us help you create a safer, more efficient lab.

Contact KINTEK today for a personalized consultation on the right heating equipment for your specific needs and to learn more about our comprehensive product range.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Automatic Laboratory Heat Press Machine

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

People Also Ask

- How do high-precision stirring and dispersion devices facilitate the solution intercalation for nano-bio-composites?

- How does a high-power ultrasonic homogenizer assist in the preparation of organic-inorganic nanocomposites?

- What is sinter metal? A Guide to Cost-Effective, Complex Metal Parts

- What are the advantages of electron beam method? Achieve Speed, Cost Savings, and Material Integrity

- What is the best catalyst for pyrolysis? A Strategic Guide to Maximizing Bio-Oil Quality and Yield

- What is the most efficient means of separating solids from surrounding liquid through gravity? Optimize with Coagulation & Clarifiers

- How does Rotavapor work? Master Gentle, Low-Temperature Solvent Evaporation

- Is carbon nanotube inhalation toxic? Understanding the Asbestos-Like Risks of Long, Rigid Nanotubes