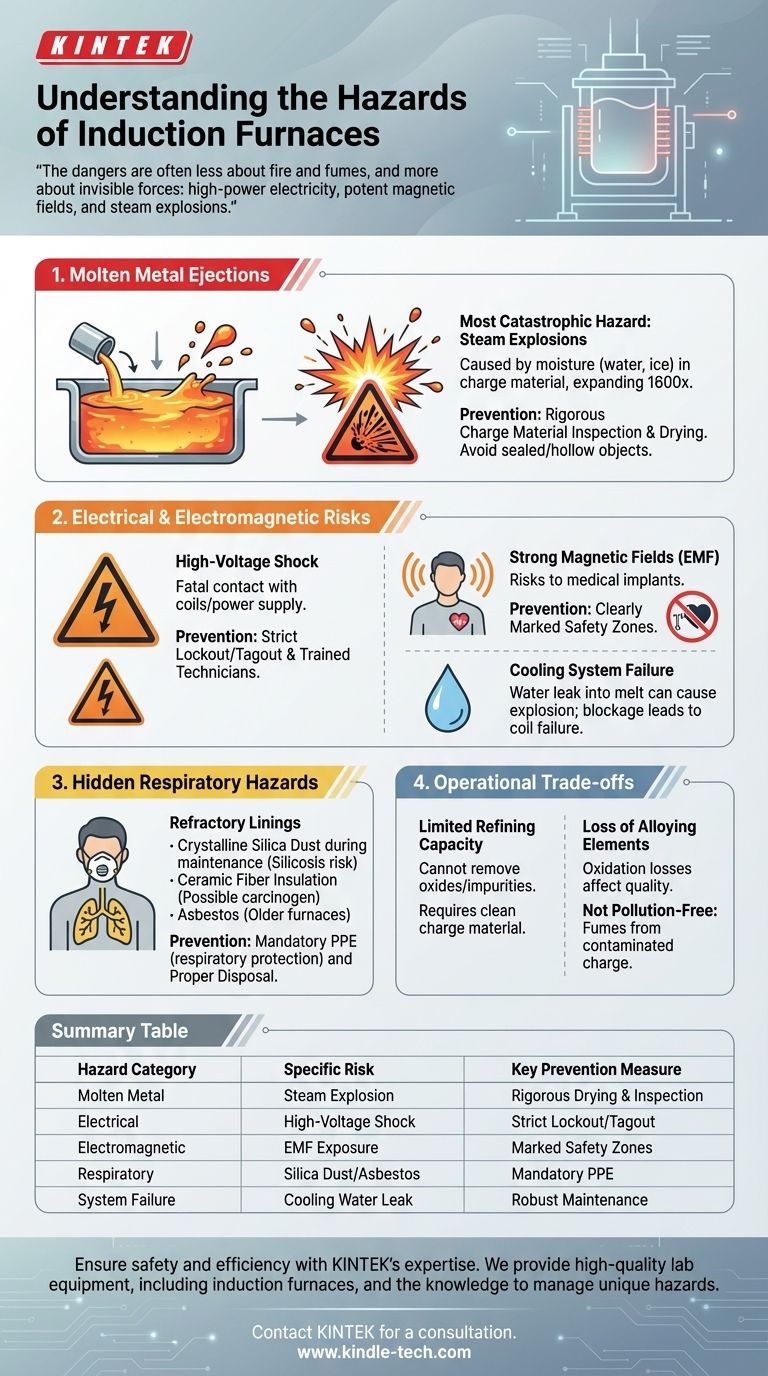

The primary hazards of an induction furnace are molten metal explosions from wet charge material, severe electrical shock, exposure to powerful magnetic fields, and respiratory damage from furnace lining materials. While known for a cleaner melting process compared to combustion furnaces, their unique operation introduces a distinct set of critical safety risks that must be actively managed.

The dangers of an induction furnace are often less about the fire and fumes of traditional melting and more about the invisible forces at play: high-power electricity, potent magnetic fields, and the violent physics of a steam explosion. Understanding these specific risks is the foundation of a safe operation.

The Most Critical Hazard: Molten Metal Ejection

The single most catastrophic event in an induction furnace operation is a steam explosion. This occurs when moisture comes into contact with the molten metal bath.

The Danger of Water and Moisture

Even a small amount of trapped water, ice, or snow on scrap material (the "charge") can be deadly. When submerged in the molten bath, this moisture instantly turns to steam, expanding to over 1,600 times its original volume. This violent expansion ejects tons of molten metal from the furnace with explosive force.

Why Charge Material Scrutiny is Essential

Proper management of charge materials is the most critical safety control. All materials must be dry and inspected for any sealed, hollow objects (like pipes or containers) that could trap moisture and act as a "bomb" when heated.

Electrical and Electromagnetic Risks

Induction furnaces operate using immense electrical power, creating two distinct but related hazards: direct electrical shock and exposure to strong magnetic fields.

High-Voltage Shock Hazards

The induction coils and the power supply unit operate at high voltages and amperages. Contact can be instantly fatal. Maintenance must only be performed by trained technicians with strict lockout/tagout procedures to ensure the equipment is fully de-energized.

Exposure to Strong Magnetic Fields (EMF)

The process of induction heating generates a powerful electromagnetic field around the furnace. This field can pose a serious risk to individuals with pacemakers, insulin pumps, or other medical implants. Clearly marked safety zones must be established to prevent inadvertent exposure.

The Critical Role of the Cooling System

The induction coils themselves are cooled by water. A failure in this system is a major hazard. A water leak can introduce moisture into the melt, leading to an explosion. A blockage can cause the coils to overheat and fail catastrophically, potentially creating an electrical arc or rupture.

Hidden Respiratory and Material Hazards

While the melting process itself is clean, the furnace structure can contain materials that become hazardous, particularly during maintenance or decommissioning.

The Risk from Refractory Linings

Many furnaces use refractory linings that contain crystalline silica. Over time, the lining degrades. During removal and replacement, this can create fine dust containing respirable crystalline silica, which can cause chronic, irreversible lung disease (silicosis).

Ceramic Fiber Insulation

Some insulation materials may be made of refractory ceramic fiber. This material is classified as a possible human carcinogen, and inhaling its fibers can cause lung damage. Proper personal protective equipment (PPE) is essential when handling it.

The Legacy of Asbestos

Older furnaces may contain asbestos insulation. If this material is disturbed, it can release fibers that lead to severe health issues, including asbestosis and mesothelioma. Disposal must be handled by certified professionals.

Understanding Operational and Process Trade-offs

Beyond immediate safety threats, certain operational characteristics can be considered process hazards that impact production and quality.

The Lack of Refining Capacity

A key drawback of induction furnaces is their inability to refine metal. Unlike other furnace types, they cannot effectively remove oxides or impurities from the charge material. This means the input materials must be clean and of a known composition to produce a quality melt.

Loss of Alloying Elements

While the temperature control is excellent, some valuable alloying elements can still be lost through oxidation. This requires careful monitoring and potential re-addition of elements to the melt, affecting cost and process control.

The Myth of "No Pollution"

Induction furnaces produce significantly less smoke, dust, and waste than arc or cupola furnaces. However, they are not pollution-free. The melting of certain metals, especially those with coatings or contaminants, can still produce harmful fumes and require an effective ventilation system.

Key Safety Priorities for Your Operation

Managing the risks of an induction furnace requires a focus on training, strict procedures, and preventative maintenance.

- If your primary focus is preventing catastrophic accidents: Your number one priority is implementing and enforcing a rigorous charge material inspection and drying protocol to eliminate moisture.

- If your primary focus is protecting personnel: Establish clear EMF safety zones, provide comprehensive electrical safety training, and mandate appropriate PPE during all lining maintenance.

- If your primary focus is reliability and longevity: Create a robust preventative maintenance schedule for the water-cooling system and power supply components to prevent catastrophic failures.

Ultimately, harnessing the efficiency of an induction furnace depends entirely on respecting its unique hazards through unwavering diligence and protocol.

Summary Table:

| Hazard Category | Specific Risk | Key Prevention Measure |

|---|---|---|

| Molten Metal | Steam Explosion | Rigorous drying and inspection of all charge materials |

| Electrical | High-Voltage Shock | Strict lockout/tagout procedures and trained technicians |

| Electromagnetic | EMF Exposure | Clearly marked safety zones, especially for personnel with implants |

| Respiratory | Silica Dust / Asbestos | Mandatory PPE during furnace lining maintenance |

| System Failure | Cooling Water Leak | Robust preventative maintenance schedule for cooling system |

Ensure your lab's safety and operational efficiency with KINTEK's expertise. Induction furnaces offer a cleaner melting process, but their unique hazards require specialized knowledge and reliable equipment. KINTEK specializes in providing high-quality lab equipment, including induction furnaces, and the consumables and safety support you need. Our team can help you select the right equipment and establish the protocols necessary to protect your personnel and your process. Contact us today to discuss how we can support your laboratory's melting applications safely and effectively. Get in touch via our contact form for a consultation.

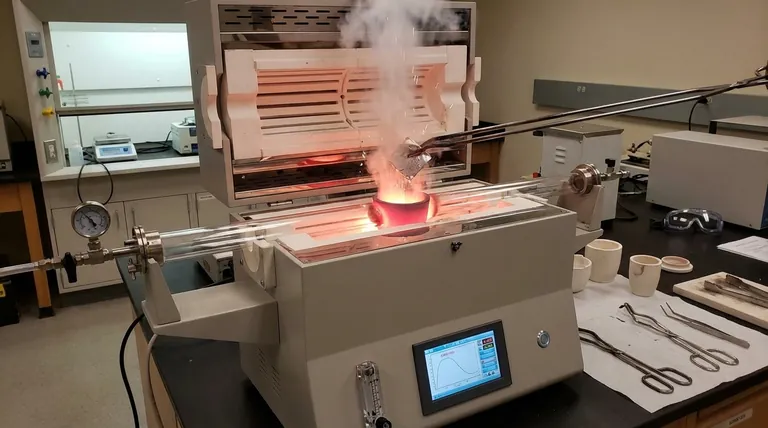

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is the melting temperature of an induction furnace? Precision Heating Up to 2000°C for Superior Metal Melting

- What is the function of the induction heating power supply in vacuum sintering? Boost Efficiency in Powder Metallurgy

- What is the temperature of induction annealing? Master Material-Specific Heat Treatment

- How does a vacuum resistance melting furnace prevent magnesium oxidation? Protect AM60 Alloy Purity

- What furnace is used for melting aluminium? Induction Furnaces for Efficient, High-Purity Melting

- What is induction furnace used for? Achieve Fast, Clean Metal Melting and Heat Treatment

- What is the difference between channel induction and coreless furnace? A Guide to Optimizing Your Metal Melting Process

- What is the effect of frequency in induction furnace? Unlock Optimal Melting Efficiency & Control