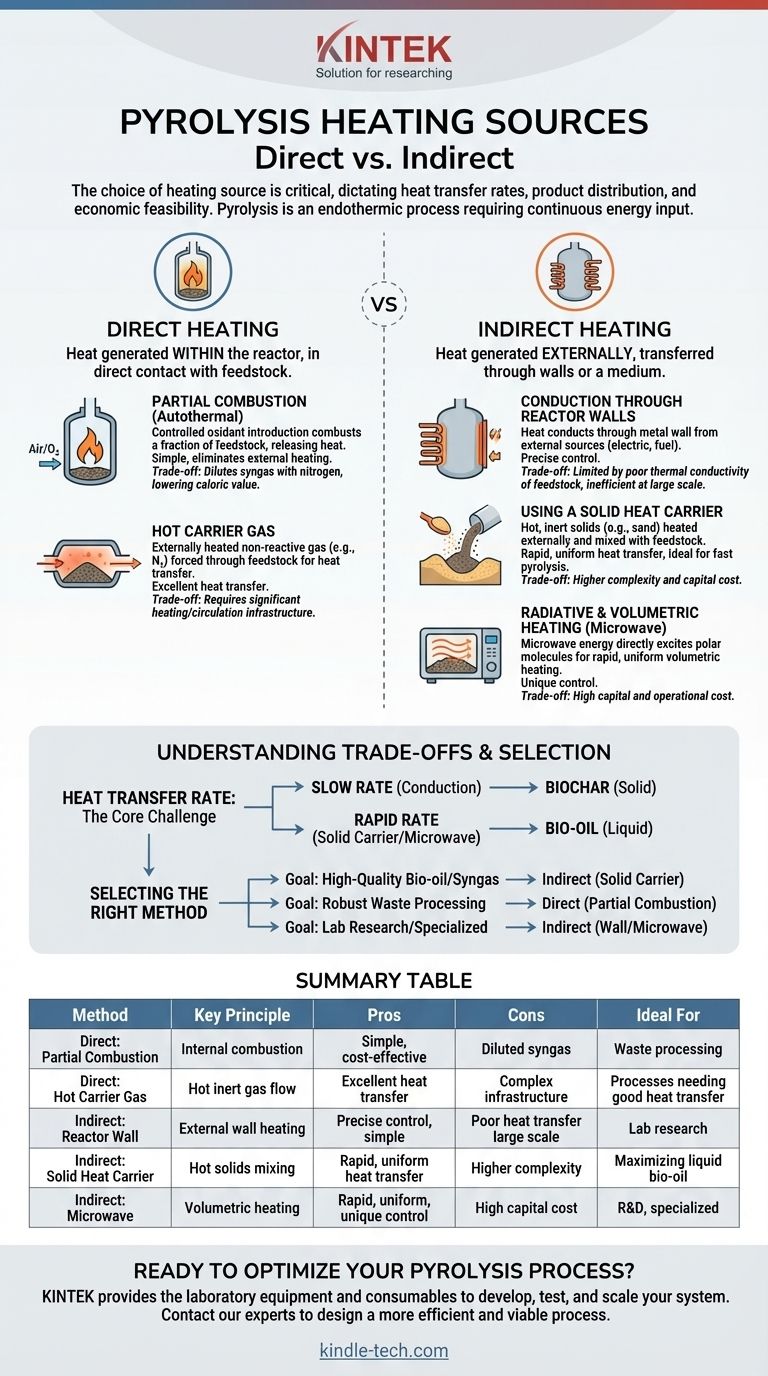

The primary heating sources for pyrolysis are classified into two main categories: direct and indirect. Direct heating involves generating heat within the reactor, often by partially combusting the feedstock itself or by using a hot carrier gas. Indirect heating applies an external energy source to the reactor wall or uses a solid heat carrier, keeping the pyrolysis reaction separate from the heat generation process.

The choice of a heating source is the most critical engineering decision in designing a pyrolysis system. It dictates not just the temperature, but the rate of heat transfer, which in turn controls the product distribution (char, oil, gas) and the overall economic feasibility of the operation.

The Two Core Principles of Pyrolysis Heating

Pyrolysis is an endothermic process, meaning it requires a continuous input of energy to break down organic material in the absence of oxygen. The way this energy is delivered fundamentally changes the reactor's design and performance.

Direct Heating

In direct heating, the heat source is in direct contact with the feedstock inside the reaction chamber. This method is often mechanically simpler as it integrates heat generation into the reactor itself.

Indirect Heating

In indirect heating, the heat is generated externally and then transferred to the feedstock, typically through the reactor walls or via a heated medium. This approach offers greater control and prevents contamination of the products.

Direct Heating Methods Explained

Direct heating methods are valued for their high thermal efficiency and simpler initial construction.

Partial Combustion (Autothermal)

The most common direct method involves introducing a controlled amount of an oxidant (like air or oxygen) into the reactor. This causes a fraction of the feedstock to combust, releasing the heat required to pyrolyze the rest.

This autothermal approach eliminates the need for a complex external heating system.

Hot Carrier Gas

In this method, a non-reactive gas like nitrogen or recycled syngas is heated externally and then forced through the feedstock bed. The hot gas directly transfers its thermal energy to the material, driving the pyrolysis reactions.

This provides excellent heat transfer but requires significant infrastructure for heating and circulating the gas.

Indirect Heating Methods Explained

Indirect heating is favored when product purity and precise temperature control are paramount.

Conduction Through Reactor Walls

This is the classic approach where the reactor vessel is heated from the outside using electric resistance heaters, combustion of fuel gas, or induction coils. The heat then conducts through the metal wall to the feedstock inside.

While simple and easy to control, this method is limited by the poor thermal conductivity of most feedstocks (like biomass) and becomes inefficient as reactor size increases.

Using a Solid Heat Carrier

To overcome the limitations of wall heating, many large-scale systems use a hot, inert solid material like sand or ceramic beads. This solid carrier is heated in a separate furnace and then mixed directly with the feedstock in the reactor.

This technique, often used in fluidized bed reactors, provides extremely rapid and uniform heat transfer, making it ideal for processes like fast pyrolysis that aim to maximize liquid oil yield.

Radiative and Volumetric Heating

Advanced methods like microwave heating provide volumetric heating. Microwave energy penetrates the feedstock and directly excites polar molecules (especially water), generating heat rapidly and uniformly throughout the material's volume.

This bypasses the slow process of thermal conduction and offers unique control over the heating process, though it comes at a higher capital and operational cost.

Understanding the Trade-offs

No single heating method is universally superior. The optimal choice depends entirely on the intended scale, feedstock, and desired products.

Simplicity vs. Product Quality

Direct heating via partial combustion is mechanically simple and cost-effective. However, if air is used as the oxidant, the resulting syngas is heavily diluted with nitrogen, significantly lowering its caloric value and limiting its use.

Control vs. Complexity

Indirect heating offers precise temperature control and yields a pure, high-energy product stream. This control comes at the cost of increased complexity, higher capital investment, and potential heat transfer bottlenecks in poorly designed systems.

The Core Challenge: Heat Transfer Rate

The central engineering problem in pyrolysis is overcoming the low thermal conductivity of the feedstock. A slow heating rate favors the production of solid biochar, while a very rapid heating rate is necessary to maximize the yield of liquid bio-oil. The chosen heating method must be able to deliver energy at the required rate for the target product.

Selecting the Right Method for Your Goal

Your choice of heating source should be a direct reflection of your project's primary objective.

- If your primary focus is on high-quality bio-oil or undiluted syngas: Indirect heating, particularly using a solid heat carrier in a fluidized bed reactor, offers the rapid and controlled heat transfer necessary to maximize liquid yields and product purity.

- If your primary focus is on robust, low-cost waste processing for energy: Direct heating via partial combustion (autothermal pyrolysis) is a pragmatic and economically viable choice, especially if the diluted syngas is to be used for on-site heat generation.

- If your primary focus is on lab-scale research or specialized material production: Indirect wall heating offers the simplest setup for precise control, while advanced methods like microwave heating provide unique capabilities for targeted and rapid reactions.

Ultimately, mastering the flow of energy into the reactor is the key to designing an effective and economically successful pyrolysis system.

Summary Table:

| Heating Method | Key Principle | Pros | Cons | Ideal For |

|---|---|---|---|---|

| Direct: Partial Combustion | Heat from controlled feedstock combustion inside reactor. | Simple, cost-effective, high thermal efficiency. | Dilutes syngas with nitrogen, lower product purity. | Low-cost waste processing, on-site heat generation. |

| Direct: Hot Carrier Gas | Hot inert gas (e.g., N₂) flows through feedstock. | Excellent heat transfer. | Requires complex gas heating/circulation infrastructure. | Processes needing good heat transfer with gas handling. |

| Indirect: Reactor Wall | External heat source (electric, fuel) heats reactor walls. | Precise temperature control, simple setup. | Poor heat transfer for large scales/insulating feedstocks. | Lab-scale research, precise control applications. |

| Indirect: Solid Heat Carrier | Hot solids (e.g., sand) mix with feedstock in reactor. | Rapid, uniform heat transfer, high product purity. | Higher complexity and capital cost. | Maximizing liquid bio-oil yield (fast pyrolysis). |

| Indirect: Microwave | Volumetric heating by exciting molecules within feedstock. | Rapid, uniform heating, unique control. | High capital/operational cost. | Specialized material production, R&D. |

Ready to Optimize Your Pyrolysis Process?

Selecting the right heating source is critical to achieving your target product yields, whether it's high-quality bio-oil, pure syngas, or biochar. The experts at KINTEK are here to help you navigate these complex engineering decisions.

We provide the laboratory equipment and consumables you need to develop, test, and scale your pyrolysis system. From bench-top reactors to analytical tools, KINTEK supplies reliable solutions for researchers and engineers focused on sustainable material and energy production.

Contact us today to discuss your project requirements and let our expertise help you design a more efficient and economically viable process.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process