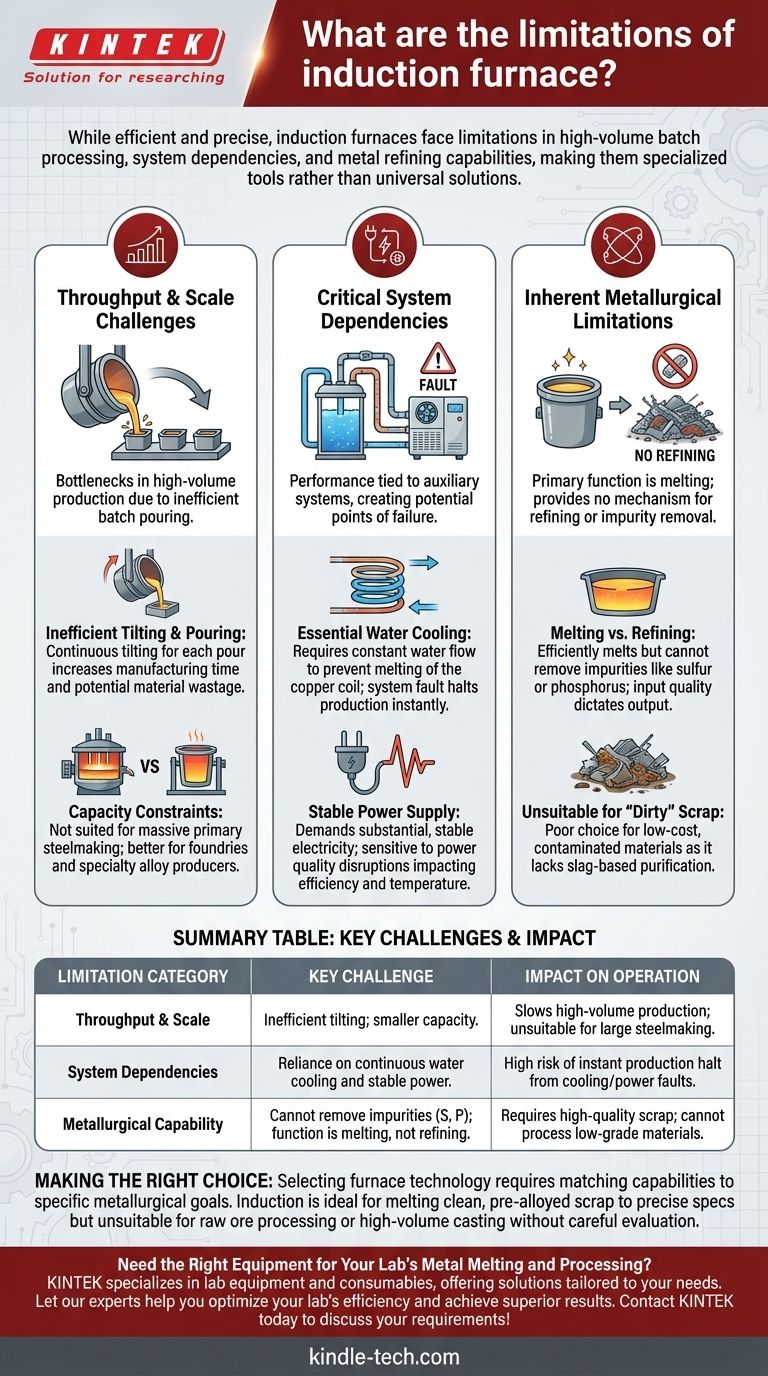

Despite their well-deserved reputation for efficiency and precision, induction furnaces are not a universal solution for all metal melting applications. Their primary limitations revolve around operational inefficiencies in high-volume batch processing, a critical dependency on auxiliary cooling systems, and an inherent inability to refine metals, which restricts the type of scrap they can effectively process.

The core issue is one of specialization. An induction furnace excels at clean, controlled melting of known-composition materials, but these advantages come with trade-offs in operational flexibility, throughput, and metallurgical capability that are critical in other industrial scenarios.

The Challenge of Throughput in Batch Operations

While excellent for specific melts, the design of many induction furnaces can create bottlenecks in high-volume production environments.

Inefficient Tilting and Pouring

For foundries producing many individual parts, the furnace must be tilted for every single pour.

This continuous tilting process can lead to increased manufacturing time and even material wastage between moulds, hindering overall throughput compared to continuous melting systems.

Capacity and Scale Constraints

Induction furnaces are generally not suited for the massive melts common in primary steelmaking, which are better handled by Electric Arc or Basic Oxygen Furnaces.

While industrial sizes are much larger than lab-scale models, they do not scale to the same capacity, making them more appropriate for foundries and specialty alloy producers rather than large steel mills.

Critical System Dependencies

An induction furnace does not operate in isolation. Its performance is critically tied to several auxiliary systems, each representing a potential point of failure.

The Essential Role of Water Cooling

The high-power copper induction coil generates immense heat and requires a constant flow of cooling water to prevent it from melting.

The system's reliability is entirely dependent on the chiller or cooling tower. A fault, such as a pump failure or water shortage, will trigger safety shutdowns and halt all production instantly.

Power Supply Requirements

Induction furnaces demand a substantial and stable electrical power supply to create the strong magnetic fields necessary for melting.

While modern units have soft-starting features to minimize grid impact, they are sensitive to power quality. Any disruption can affect melting efficiency and temperature control.

Inherent Metallurgical Limitations

Perhaps the most significant limitation is what an induction furnace cannot do. Its function is almost exclusively melting, not refining.

Melting vs. Refining

The induction process is extremely efficient at melting metal. However, it provides no mechanism for removing undesirable elements like sulfur and phosphorus from the molten bath.

The stirring action creates a homogenous mixture but does not facilitate slag-based chemical reactions needed for purification. This means the quality of the input material directly dictates the quality of the output.

Unsuitability for "Dirty" Scrap

Because it cannot refine metal, an induction furnace is a poor choice for processing low-cost, contaminated, or "dirty" scrap.

Other furnace types use slag and oxygen lances to burn off impurities, allowing them to turn low-grade materials into high-quality metal. This is not feasible in a standard induction furnace.

Understanding the Trade-offs

The limitations of induction furnaces are often the direct inverse of their strengths. Understanding this balance is key to selecting the right technology.

Precision at the Cost of Refining

The clean, contained, and controlled environment that gives the induction furnace its high temperature accuracy and minimal pollution is precisely what prevents robust slag-based refining. There is no excess energy or violent chemical reaction to purify the metal.

The Channel Furnace Constraint

A specific design, the channel induction furnace, is highly efficient for holding molten metal at temperature but has a major operational constraint.

It requires a continuous loop of molten metal to function, meaning it can't easily be shut down or started from cold. This limits its use primarily to holding applications or melting low-temperature alloys.

Making the Right Choice for Your Application

Selecting the correct furnace technology requires matching its capabilities to your specific metallurgical goal.

- If your primary focus is melting clean, pre-alloyed scrap to precise specifications: The induction furnace is the ideal choice for its control, efficiency, and cleanliness.

- If your primary focus is high-volume production of castings: The batch-oriented pouring process may introduce a significant bottleneck and should be carefully evaluated.

- If your primary focus is processing raw ore or low-grade scrap metal: An induction furnace is unsuitable, as it lacks the essential chemical refining capabilities required for this task.

Ultimately, an induction furnace is a masterful tool for remelting and alloying, but it is not designed for the heavy-duty refining work that defines other areas of metallurgy.

Summary Table:

| Limitation Category | Key Challenge | Impact on Operation |

|---|---|---|

| Throughput & Scale | Inefficient tilting for batch pouring; smaller capacity compared to arc furnaces. | Slows high-volume production; unsuitable for massive steelmaking melts. |

| System Dependencies | Critical reliance on continuous water cooling and stable, high-power electrical supply. | High risk of instant production halt from cooling/power faults. |

| Metallurgical Capability | Cannot remove impurities (e.g., sulfur, phosphorus); function is melting, not refining. | Requires high-quality, clean scrap; cannot process low-grade or "dirty" materials. |

Need the Right Equipment for Your Lab's Metal Melting and Processing?

Understanding the limitations of different furnace types is crucial for selecting the right technology for your specific application. KINTEK specializes in lab equipment and consumables, offering solutions tailored to your metallurgical needs—whether you require precise melting, high-throughput processing, or specialized refining capabilities.

Let our experts help you optimize your lab's efficiency and achieve superior results. We provide reliable equipment and expert support to ensure your processes run smoothly.

Contact KINTEK today to discuss your laboratory requirements and find the perfect solution for your metal processing challenges!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What is the primary advantage of using a tube furnace? Achieve Superior Temperature and Atmosphere Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis