The primary limitations of physical vapor deposition (PVD) are its "line-of-sight" nature, which makes it difficult to coat complex shapes, and process-specific constraints such as material requirements and the potential for surface defects. Unlike chemical vapor deposition (CVD), where a gas uniformly coats all surfaces, PVD involves physically transporting material from a source to a substrate in a straight line, creating "shadows" on intricate parts.

The core challenge of PVD isn't about whether it can create a quality coating, but rather where it can place that coating. Its effectiveness is fundamentally tied to the direct, unobstructed path between the material source and the target surface.

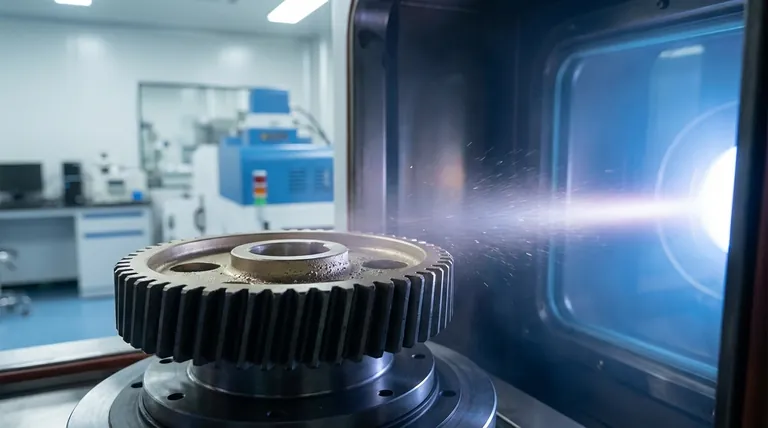

The Core Limitation: The "Line-of-Sight" Problem

Physical vapor deposition works by bombarding a solid source material (the "target") with energy, causing atoms or molecules to be ejected. These ejected particles then travel through a vacuum and condense onto the substrate, forming a thin film.

What "Line-of-Sight" Means

The particles travel in a straight trajectory from the source to the substrate. Any part of the substrate that is not in the direct line of sight of the source will not be coated.

This is the single most significant difference when comparing PVD to the non-line-of-sight nature of Chemical Vapor Deposition (CVD), where a precursor gas can flow around and into complex geometries.

Difficulty with Complex Geometries

Because of this direct-path requirement, PVD struggles to coat the inside of tubes, undercuts, or the backside of an object without complex and often expensive fixturing to rotate the part during the process.

Even with rotation, achieving a perfectly uniform coating inside sharp corners or deep channels is exceptionally difficult.

Process-Specific Constraints

The term "PVD" covers several different techniques, each with its own unique set of limitations. The method used to vaporize the source material introduces specific trade-offs.

Material Requirements for Arc Deposition

One common PVD method, arc vapor deposition, can only be used with electrically conductive source materials. The process relies on creating an electric arc on the target surface to vaporize it, which is not possible with insulating materials like many ceramics.

Surface Defects from "Macros"

Arc deposition is also known for ejecting microscopic molten globules, often called "macros", from the source material. These droplets can become embedded in the growing film, creating surface nodules and other defects that can compromise the coating's integrity or finish.

Deposition Rates and Heating

Other PVD processes, like sputtering, can have relatively low deposition rates compared to thermal evaporation or CVD, increasing process time and cost. Furthermore, some methods, such as anodic arc deposition, generate significant radiant heat, which can be problematic for temperature-sensitive substrates.

Understanding the Trade-offs: PVD vs. CVD

To fully grasp PVD's limitations, it's useful to contrast it directly with its chemical counterpart, CVD, which relies on chemical reactions on a substrate's surface.

Coating Coverage vs. Operating Temperature

CVD excels at creating highly uniform (conformal) coatings on components with complex shapes because the precursor gas reaches every surface. However, CVD often requires very high temperatures to initiate the chemical reaction.

PVD, while limited to line-of-sight, can often be performed at much lower temperatures, making it suitable for materials that cannot withstand the heat of a CVD process.

Chamber Size and Scalability

Both processes are limited by the size of their vacuum chambers, making it difficult to coat very large surfaces. Parts must typically be broken down into individual components before being placed in the coating chamber for either method.

Making the Right Choice for Your Application

The decision between PVD and other coating methods depends entirely on the geometry of your part and your material requirements.

- If your primary focus is coating complex internal surfaces or 3D parts uniformly: CVD is almost always the superior choice due to its non-line-of-sight nature.

- If your primary focus is depositing a high-purity film on a flat or simple external surface: PVD is an excellent, often lower-temperature and highly controllable, option.

- If your part is sensitive to high temperatures: A low-temperature PVD process like sputtering is likely a better fit than a high-temperature CVD process.

Ultimately, understanding a deposition method's limitations is the key to selecting the most effective process for your specific goal.

Summary Table:

| Limitation | Key Challenge | Impact on Coating |

|---|---|---|

| Line-of-Sight Nature | Particles travel in straight lines, creating shadows | Inability to uniformly coat complex geometries, undercuts, and internal surfaces |

| Material Requirements (Arc PVD) | Requires electrically conductive source materials | Cannot be used with insulating materials like many ceramics |

| Surface Defects (Arc PVD) | Ejection of microscopic molten globules ("macros") | Creates nodules and compromises coating integrity and finish |

| Deposition Rate & Heat | Some methods have low deposition rates or generate significant heat | Increases process time/cost and can damage temperature-sensitive substrates |

| Chamber Size | Limited by vacuum chamber dimensions | Difficult to coat very large surfaces in a single batch |

Struggling to choose the right coating method for your complex lab components? KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. Our experts can help you navigate the trade-offs between PVD, CVD, and other techniques to find the optimal solution for your specific application, ensuring high-quality, durable coatings for your materials. Contact us today via our [#ContactForm] to discuss your project and discover how we can enhance your lab's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Coating Solution for Sensitive Materials

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition