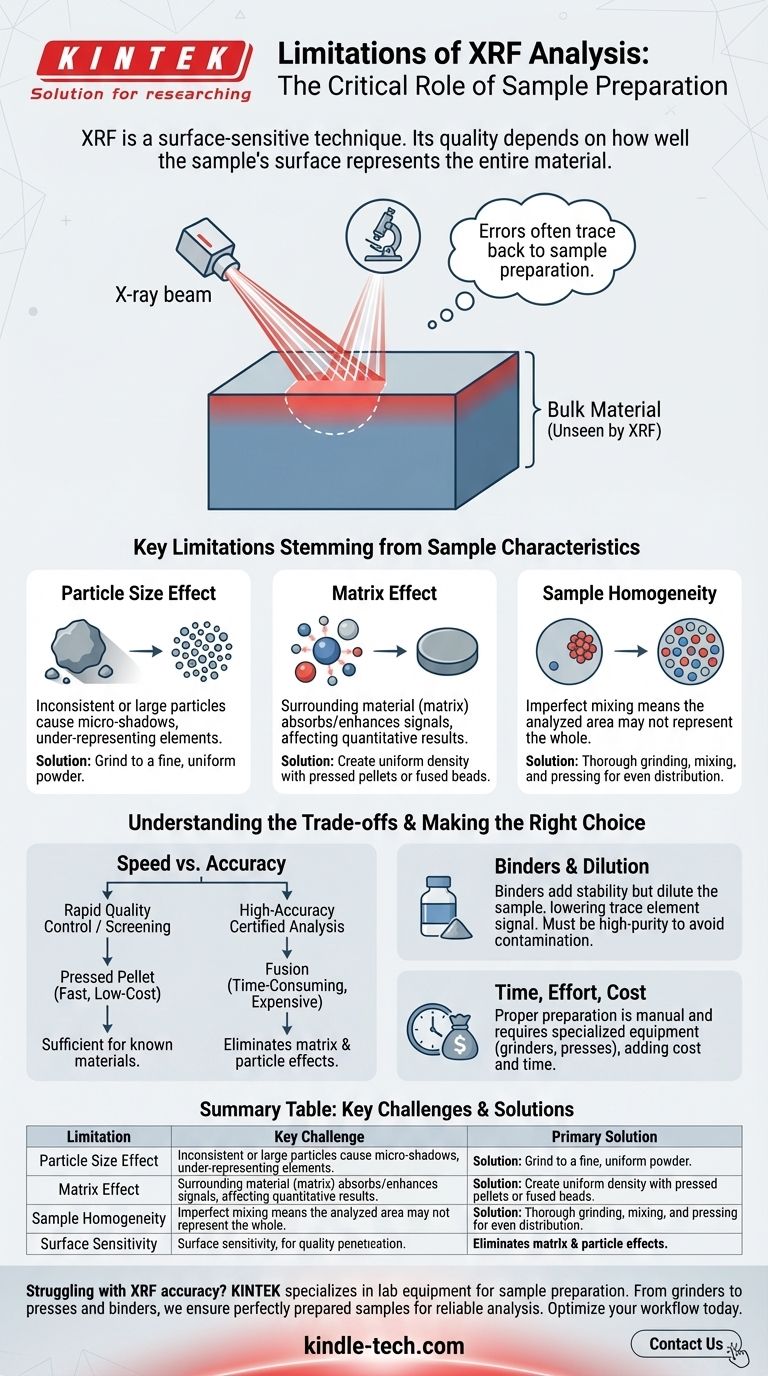

The primary limitations of X-Ray Fluorescence (XRF) analysis are not found in the technique's underlying physics but in the physical preparation of the sample. While a powerful and non-destructive method, the quality of XRF data is fundamentally dependent on how a sample is presented to the instrument. Errors and inaccuracies almost always trace back to issues of sample homogeneity, particle size, and surface quality.

The core takeaway is that XRF is a surface-sensitive analytical technique. Its limitations are therefore defined by how well the sample's surface represents the entire material, making meticulous sample preparation the most critical factor for achieving accurate results.

The Central Role of Sample Preparation

XRF analysis works by bombarding a sample with high-energy X-rays, causing the atoms within to fluoresce, or emit, secondary X-rays. The instrument detects the energy and intensity of these secondary X-rays to identify and quantify the elements present.

Because the primary X-rays only penetrate a shallow depth into the material, the technique is inherently surface-focused. This single fact is the source of most of its practical limitations.

Why Surface Quality is Paramount

If the surface is not a perfect representation of the bulk material, the results will be skewed. A sample must be homogeneous, flat, and infinitely thick relative to the X-ray penetration depth for the data to be accurate.

The Goal of Preparation

All sample preparation steps—crushing, grinding, pressing, or fusing—are designed to overcome these physical limitations. The goal is to create a sample specimen that presents a uniform and representative face to the X-ray beam.

Key Limitations Stemming from Sample Characteristics

The challenges in XRF are almost entirely related to overcoming physical and chemical interferences within the sample itself, known as "matrix effects."

The Particle Size Effect

Inconsistent or large particle sizes are a major source of error. Large particles can create micro-shadows, absorbing or scattering the fluorescent X-rays from smaller surrounding particles before they reach the detector.

This leads to an under-representation of some elements and an over-representation of others. Proper grinding to a fine, uniform powder is the only way to mitigate this limitation.

The Matrix Effect

The material surrounding the element of interest (the matrix) can absorb or enhance its fluorescent signal. For example, heavy elements in the matrix can absorb the signal from lighter elements, making their concentration appear lower than it is.

This is a significant limitation for quantitative analysis. Creating a pressed pellet or, for greater accuracy, a fused bead helps create a uniform matrix density to make these effects more predictable and correctable.

Sample Homogeneity

If a sample is not perfectly mixed, the small area analyzed by the X-ray beam may not be representative of the whole. A pocket of high concentration of one element will produce an inaccurate bulk reading.

This limitation is overcome by thorough grinding, mixing, and pressing, which distributes all components evenly throughout the sample pellet.

Understanding the Trade-offs

Every step taken to prepare a sample is a balance of effort, cost, and the required quality of the final result. Understanding these trade-offs is key to managing XRF's limitations.

Method Selection: Speed vs. Accuracy

The pressed pellet method is common because it is fast, low-cost, and produces high-quality results for many applications. It involves pressing the powdered sample into a dense, flat disc.

However, it may not completely eliminate matrix effects in complex materials. For the highest accuracy, fusion—dissolving the sample in a glass flux like lithium borate—creates a perfectly homogeneous sample but is more time-consuming and expensive.

The Role of Binders and Dilution

Binders are often mixed with sample powders to help form a robust, stable pellet that won't break. This introduces a trade-off.

The binder dilutes the sample, which can lower the signal intensity, making it harder to detect trace elements. The binder must also be free of any elements you are trying to measure to avoid contamination.

Time, Effort, and Cost

Proper sample preparation is a manual, often time-consuming process. The need for specialized equipment like grinders and presses adds to the cost. This practical limitation means that for high-throughput needs, one must balance the required accuracy against the time spent on each sample.

Making the Right Choice for Your Goal

Effectively using XRF requires matching your sample preparation protocol to your analytical objective.

- If your primary focus is high-accuracy, certified quantitative analysis: You must use a rigorous sample preparation method like fusion to eliminate particle size and mineralogical effects completely.

- If your primary focus is rapid quality control or screening of known materials: A simple pressed pellet method is often sufficient, as you are likely looking for deviations from a known standard rather than absolute values.

- If your primary focus is measuring trace elements (parts-per-million): Your main concern is contamination, so you must use clean grinding equipment and high-purity binders.

By understanding that XRF's limitations are fundamentally linked to sample preparation, you can control them and transform it into an exceptionally reliable and powerful analytical tool.

Summary Table:

| Limitation | Key Challenge | Primary Solution |

|---|---|---|

| Particle Size Effect | Large particles cause signal scattering | Grind to fine, uniform powder |

| Matrix Effect | Surrounding materials absorb/enhance signals | Use pressed pellets or fused beads |

| Sample Homogeneity | Surface may not represent bulk material | Thorough grinding, mixing, and pressing |

| Surface Sensitivity | Analysis limited to shallow penetration depth | Create flat, representative surfaces |

Struggling with XRF analysis accuracy? The key to reliable results lies in proper sample preparation. At KINTEK, we specialize in laboratory equipment and consumables designed to overcome XRF limitations. Our range of sample preparation tools—including grinders, presses, and high-purity binders—ensures your samples are perfectly prepared for accurate, repeatable analysis. Whether you need rapid quality control solutions or high-accuracy quantitative analysis, KINTEK has the expertise and equipment to support your laboratory needs. Contact us today to discuss how we can help optimize your XRF workflow and deliver the precise results you demand.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- What is the laboratory apparatus for mixing? Choose the Right Tool for Your Sample Volume and Viscosity

- What is calcination? A Guide to High-Temperature Purification and Transformation

- What is the temperature of activated carbon regeneration? Unlock the 1000°F Process for Reuse

- What are the disadvantages of DC magnetron sputtering? Key Limitations for Your Lab

- How does a laboratory constant temperature drying oven assist in processing raw COF products? Master Material Activation

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research

- What is the effect of sintering temperature? Master the Key to Material Density and Strength

- What is the capacity of a continuous furnace? Unlock High-Volume Sintering from 50 to 1000 kg/day