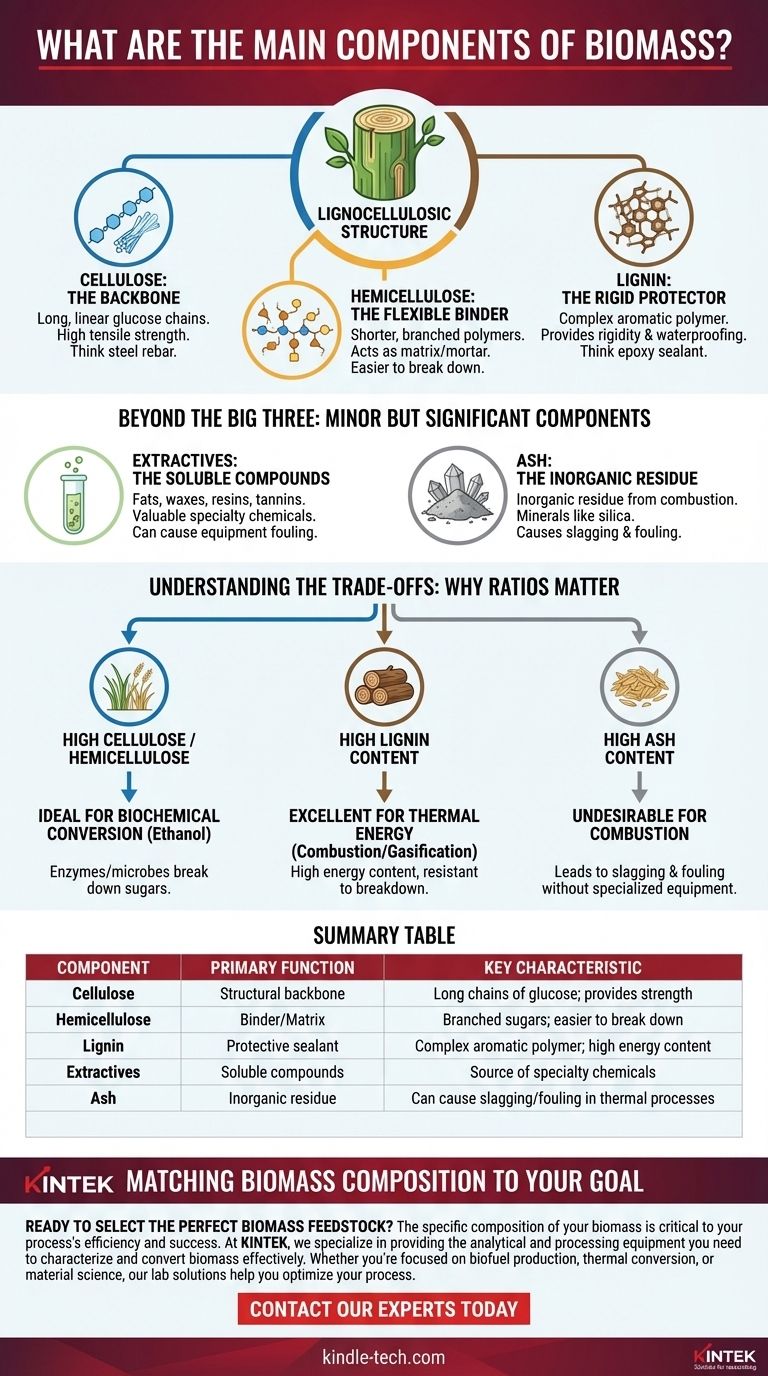

At its core, all plant-based biomass is primarily composed of three main biopolymers: cellulose, hemicellulose, and lignin. Together, these form the lignocellulosic structure that gives plants their rigidity and form. While these three are the dominant components, other materials like extractives and inorganic ash are also present and play a significant role in how biomass behaves.

The true technical insight is not just knowing the names of the components, but understanding that their specific ratio dictates the energy content, structural integrity, and ultimate suitability of any biomass source for conversion into fuel, chemicals, or materials.

The Structural Building Blocks: A Closer Look

To properly evaluate a biomass feedstock, you must understand the function and properties of its primary constituents. These components are intertwined within the plant's cell walls.

Cellulose: The Backbone of Biomass

Cellulose is the most abundant organic polymer on Earth. It consists of long, linear chains of glucose molecules linked together.

These chains are highly ordered and pack tightly, forming crystalline microfibrils. Think of cellulose as the steel rebar in reinforced concrete—it provides immense tensile strength and structural integrity. Its high glucose content makes it the primary target for producing bioethanol through fermentation.

Hemicellulose: The Flexible Binder

Hemicellulose is a shorter, highly branched polymer made up of various five- and six-carbon sugars (not just glucose). It acts as a matrix that cross-links cellulose microfibrils.

Continuing the analogy, hemicellulose is the mortar and connecting ties that hold the cellulose "rebar" in place, creating a cohesive structure. Because it is less crystalline and more varied in composition, it is generally easier to break down than cellulose.

Lignin: The Rigid Protector

Lignin is a complex, aromatic polymer that fills the spaces between cellulose and hemicellulose. It provides rigidity, compression strength, and waterproofing to the cell wall.

Lignin is the epoxy or waterproof sealant that encases the entire structure, protecting it from microbial attack and physical stress. While it has a high energy content, its complex and robust chemical structure makes it very difficult to break down, presenting a major challenge in biofuel and pulping processes.

Beyond the Big Three: Minor but Significant Components

While lignocellulose forms the bulk of biomass, other components can significantly impact its processing and value.

Extractives: The Soluble Compounds

These are non-structural compounds that can be removed with solvents. They include fats, waxes, resins, tannins, and simple sugars.

Though a minor fraction by weight, extractives can be a source of valuable specialty chemicals. However, they can also cause issues like corrosion or fouling in processing equipment.

Ash: The Inorganic Residue

Ash is the inorganic, non-combustible portion of biomass that remains after complete combustion. It consists of minerals absorbed from the soil, such as silica, potassium, and calcium.

The amount and composition of ash are critical for thermal conversion processes. High ash content, particularly with certain minerals, can lead to slagging and fouling in boilers, reducing efficiency and increasing maintenance costs.

Understanding the Trade-offs: Why Ratios Matter

The relative proportions of these components vary widely between different types of biomass (e.g., hardwoods, softwoods, grasses, agricultural residues) and even within the same plant. This variation creates critical performance trade-offs.

High Cellulose/Hemicellulose Content

Biomass like grasses and agricultural residues (e.g., corn stover) are often rich in cellulose and hemicellulose. This makes them ideal candidates for biochemical conversion, where enzymes and microbes break down the sugars into ethanol or other chemicals.

High Lignin Content

Woody biomass, especially hardwoods, has a high lignin content. This high-density material is excellent for direct combustion or gasification, as lignin has a higher energy content per unit mass than cellulose. However, this same lignin makes it more resistant and costly to process for pulp or liquid fuels.

High Ash Content

Some agricultural residues, like rice husks or straws, are known for high silica (ash) content. While the organic matter is still valuable, the high ash percentage can make them undesirable for combustion without specialized equipment, as it leads to low melting-point ash that fouls heat exchangers.

Matching Biomass Composition to Your Goal

The optimal biomass feedstock is entirely dependent on your end-use application. To make an informed decision, you must align the material's chemical profile with your process requirements.

- If your primary focus is biofuel production (ethanol): Seek out feedstocks with high cellulose and hemicellulose content, as these sugars are the direct precursors for fermentation.

- If your primary focus is thermal energy (combustion or gasification): Prioritize feedstocks with high lignin content and low ash and moisture for maximum energy yield and minimal operational issues.

- If your primary focus is material science (pulp/paper or composites): The balance is key; high cellulose provides fiber strength, but the lignin content dictates the intensity of the chemical processing required for its removal.

By understanding the fundamental composition of biomass, you can move from simply sourcing a feedstock to strategically selecting the optimal raw material for your specific technical application.

Summary Table:

| Component | Primary Function | Key Characteristic |

|---|---|---|

| Cellulose | Structural backbone | Long chains of glucose; provides strength |

| Hemicellulose | Binder/Matrix | Branched sugars; easier to break down |

| Lignin | Protective sealant | Complex aromatic polymer; high energy content |

| Extractives | Soluble compounds | Source of specialty chemicals |

| Ash | Inorganic residue | Can cause slagging/fouling in thermal processes |

Ready to select the perfect biomass feedstock for your energy or material production goals? The specific composition of your biomass is critical to your process's efficiency and success. At KINTEK, we specialize in providing the analytical and processing equipment you need to characterize and convert biomass effectively. Whether you're focused on biofuel production, thermal conversion, or material science, our lab solutions help you optimize your process from feedstock to final product. Contact our experts today to discuss how we can support your biomass projects with precision equipment and consumables.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Polyethylene Separator for Lithium Battery

People Also Ask

- What are the structures of molds? Discover the Microscopic Filaments That Build a Colony

- What is the main advantage of annealing? Restore Ductility and Relieve Internal Stress for Better Workability

- What is the standard for Aluminium heat treatment? Master the Temper Designation System for Optimal Properties

- What are the advantages of using a vacuum filtration system? Maximize Efficiency in Rice Husk Residue Treatment

- What is a rotary vacuum evaporator? A Guide to Gentle, Efficient Solvent Removal

- What is the primary function of an ultrasonic generator in graphite exfoliation? Unlock High-Quality Graphene Production

- Why is a constant temperature shaker utilized in Methylene Blue adsorption experiments? Ensure Precise Data Integrity

- What is the difference between melting and sintering? A Guide to Solid-State vs. Liquid-State Processes