The primary methods of chemical vapor deposition (CVD) are categorized by the type of energy used to initiate the reaction and the operating pressure of the chamber. Key methods include Thermal CVD, which uses heat; Plasma-Enhanced CVD (PECVD), which uses plasma; and Photo-Assisted CVD, which uses light. These processes are also classified as either Low-Pressure CVD (LPCVD) or Atmospheric Pressure CVD (APCVD), which fundamentally changes the deposition characteristics.

The core principle to understand is that all CVD methods are engineered solutions to the same problem: how to supply enough energy to a chemical gas to make it react and form a solid film on a surface. The choice of method is therefore a strategic decision based on the temperature sensitivity of your material and the desired quality of the final film.

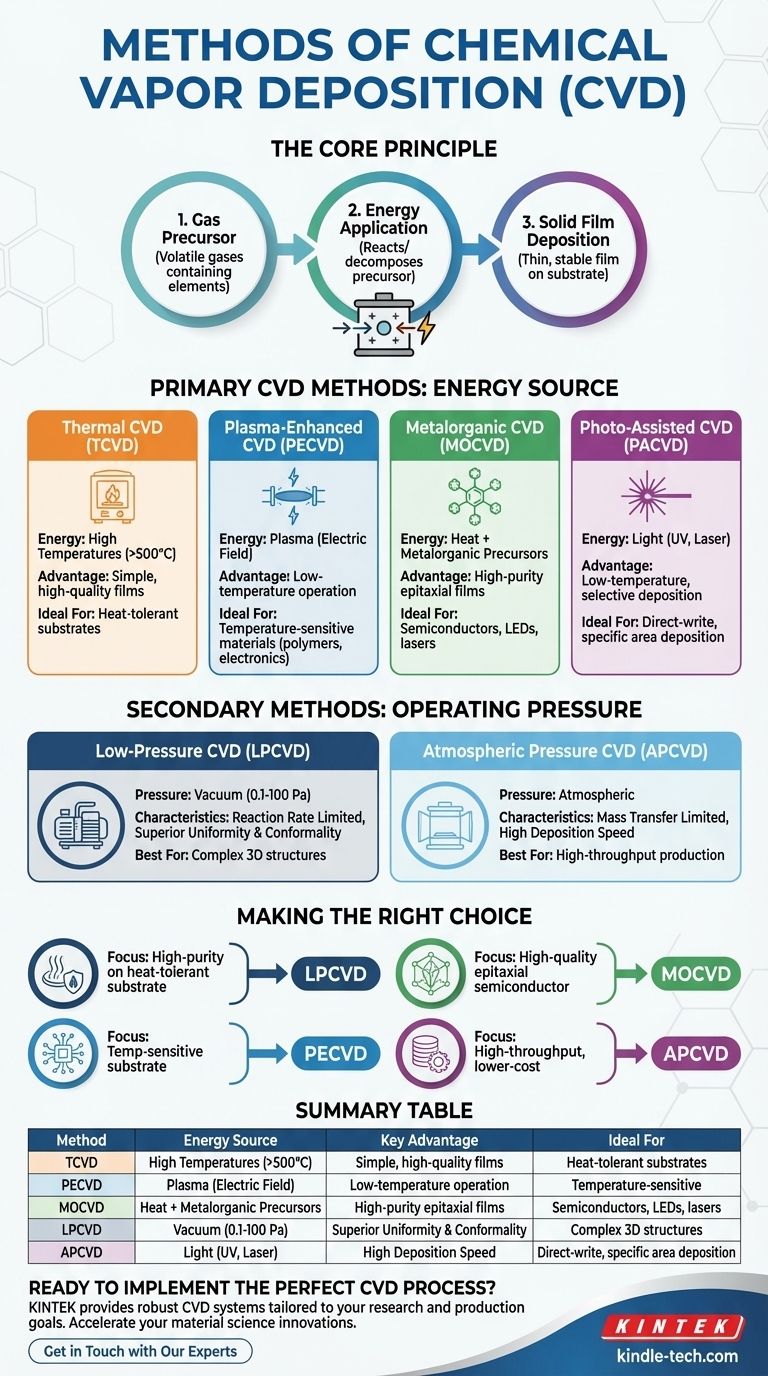

The Core Principle: How All CVD Methods Work

Before examining the differences, it's crucial to understand the fundamental process that unites all CVD techniques. It is a three-step sequence that transforms gas into a solid layer.

From Gas Precursor to Solid Film

The process begins with one or more volatile chemical gases, known as precursors, which contain the elements you wish to deposit. These precursors are introduced into a reaction chamber.

Energy is then applied to the system, causing the precursor gases to react or decompose on or near the surface of the target object, called the substrate.

The final step is the deposition of the solid reaction product onto the substrate, forming a thin, stable film. Gaseous byproducts are then pumped out of the chamber.

Primary CVD Methods: Differentiated by Energy Source

The most significant distinction between CVD methods is how they supply the energy needed to drive the chemical reaction.

Thermal CVD (TCVD)

This is the most fundamental form of CVD. It relies purely on high temperatures (often several hundred to over a thousand degrees Celsius) to provide the activation energy for the reaction.

The substrate itself is heated, and the reaction occurs directly on its hot surface. While simple, this method is only suitable for substrates that can withstand extreme heat.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electric field to generate a plasma (an ionized gas) inside the reaction chamber. This high-energy plasma effectively breaks down the precursor gases.

The key advantage of PECVD is its ability to deposit high-quality films at much lower temperatures than Thermal CVD, making it ideal for heat-sensitive substrates like polymers or complex electronic devices.

Metalorganic CVD (MOCVD)

MOCVD is a specialized form of Thermal CVD defined by its use of metalorganic precursors—compounds containing a metal-carbon bond.

This technique is the cornerstone of the modern semiconductor industry, used to create the high-purity, single-crystal films required for manufacturing LEDs, lasers, and high-performance transistors.

Photo-Assisted CVD (PACVD)

This method, which includes Laser CVD (LCVD), uses light—typically from a UV lamp or a laser—to transfer energy to the precursor gases.

The light provides the necessary energy to break chemical bonds and initiate the deposition process, again allowing for low-temperature operation. Using a focused laser beam also allows for direct-write, selective deposition on specific areas of the substrate.

A Second Axis of Classification: Operating Pressure

Independent of the energy source, CVD processes are also defined by the pressure inside the reaction chamber. This choice has a profound impact on the final film's properties.

Low-Pressure CVD (LPCVD)

LPCVD is conducted in a vacuum (typically 0.1 to 100 Pa). The reduced pressure increases the mean free path of gas molecules, meaning they travel further before colliding.

This results in exceptionally uniform and pure films that conform perfectly to complex surface topologies. In LPCVD, the process is reaction rate limited, meaning the deposition speed is controlled by the chemical reaction kinetics at the substrate surface.

Atmospheric Pressure CVD (APCVD)

APCVD operates at normal atmospheric pressure. This simplifies the reactor design and allows for very high deposition rates.

However, the high pressure means the process is often mass transfer limited. The speed is constrained by how fast precursor gases can diffuse through a boundary layer to reach the substrate, which can lead to lower purity and uniformity compared to LPCVD.

Understanding the Trade-offs

Choosing a CVD method involves balancing temperature constraints, desired film quality, and manufacturing efficiency.

Temperature vs. Quality

The primary trade-off is between the substrate's heat tolerance and the film quality. If your substrate can handle high heat, Thermal CVD or LPCVD often produce excellent crystalline films. If not, PECVD is the go-to solution for achieving quality films at low temperatures.

Conformality vs. Speed

LPCVD offers superior conformality, meaning it can uniformly coat intricate, three-dimensional structures. APCVD, on the other hand, offers much higher deposition speed, making it suitable for high-throughput applications where perfect uniformity is less critical.

CVD vs. Physical Vapor Deposition (PVD)

CVD's main advantage over PVD techniques like sputtering is its ability to deposit conformal films. PVD is a line-of-sight process and struggles to coat undercuts or complex geometries, whereas the gaseous nature of CVD precursors allows them to reach and coat all exposed surfaces uniformly.

Making the Right Choice for Your Goal

Your application's specific requirements will dictate the optimal CVD method.

- If your primary focus is high-purity, uniform films on a heat-tolerant substrate: LPCVD is the standard choice for its excellent quality and conformality.

- If your primary focus is depositing on a temperature-sensitive substrate like a polymer or completed semiconductor device: PECVD is the ideal solution to avoid thermal damage.

- If your primary focus is creating high-quality epitaxial semiconductor films for electronics or LEDs: MOCVD is the industry-leading technique for its unmatched control over crystalline structure.

- If your primary focus is high-throughput, lower-cost production where ultimate conformality isn't critical: APCVD is a viable option for its speed and simpler equipment.

Ultimately, understanding these distinct methods empowers you to select the precise tool required to build materials from the atom up.

Summary Table:

| Method | Energy Source | Key Advantage | Ideal For |

|---|---|---|---|

| Thermal CVD (TCVD) | Heat | Simple, high-quality films | Heat-tolerant substrates |

| Plasma-Enhanced CVD (PECVD) | Plasma | Low-temperature operation | Temperature-sensitive materials (polymers, electronics) |

| Metalorganic CVD (MOCVD) | Heat (Metalorganic precursors) | High-purity epitaxial films | Semiconductors, LEDs, lasers |

| Low-Pressure CVD (LPCVD) | Varies (Operates under vacuum) | Superior uniformity & conformality | Coating complex 3D structures |

| Atmospheric Pressure CVD (APCVD) | Varies (Operates at atm. pressure) | High deposition speed & throughput | High-volume production |

Ready to Implement the Perfect CVD Process?

Choosing the right Chemical Vapor Deposition method is critical for achieving your desired film properties, whether you need low-temperature processing with PECVD or high-purity epitaxial growth with MOCVD.

KINTEK is your trusted partner for all your laboratory equipment needs. We specialize in providing robust and reliable CVD systems and consumables tailored to your specific research and production goals. Our experts can help you select the ideal equipment to enhance your lab's capabilities and accelerate your material science innovations.

Contact us today to discuss your project requirements and discover how KINTEK's solutions can drive your success.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application