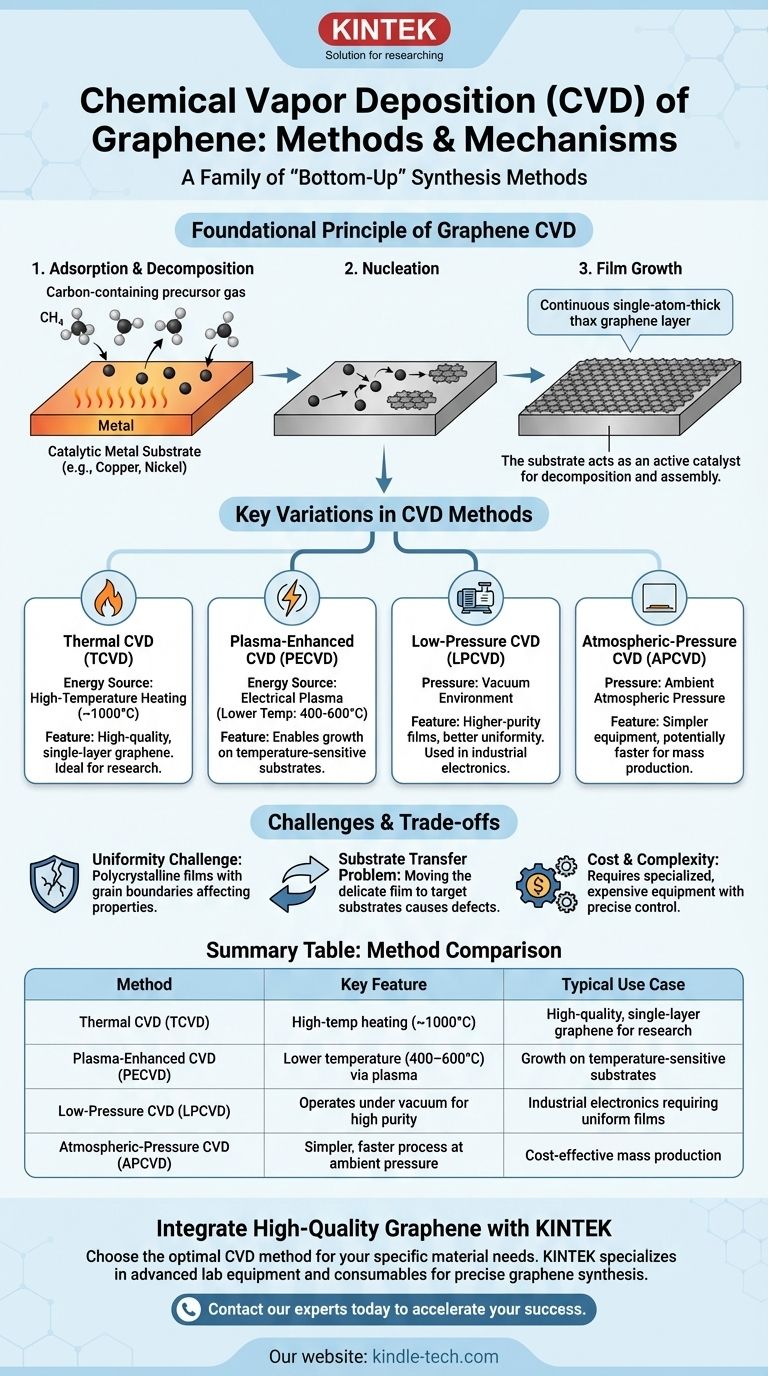

The primary method of chemical vapor deposition (CVD) for graphene involves using a carbon-containing gas (precursor) that decomposes at high temperatures on a catalytic metal substrate, typically copper or nickel. The carbon atoms then arrange themselves into the hexagonal lattice of graphene on the metal's surface. While this is the core principle, various "methods" are essentially modifications of this process, distinguished by factors like pressure, temperature, and the energy source used to drive the reaction.

Chemical Vapor Deposition (CVD) is not a single technique but a family of "bottom-up" synthesis methods. The core principle remains the same—building graphene atom-by-atom from a gas—but the specific conditions are adjusted to control the final quality, cost, and scale of production.

The Foundational Principle of Graphene CVD

Chemical Vapor Deposition is considered the most promising path toward industrial-scale production of high-quality graphene. It stands in contrast to "top-down" methods like exfoliation, which start with bulk graphite and separate it into layers.

The "Bottom-Up" Approach

CVD builds graphene from its fundamental building blocks. Carbon-containing precursor gases are introduced into a reaction chamber where they interact with a catalyst.

The Role of the Catalyst Substrate

The substrate is not merely a surface for growth; it is an active catalyst. Metals like copper and nickel are commonly used because they facilitate the decomposition of the precursor gas and the subsequent assembly of carbon atoms into a graphene film.

The Growth Mechanism in Three Steps

- Adsorption & Decomposition: A carbon precursor gas, such as methane (CH₄), is introduced into the chamber. It adsorbs onto the hot metal surface and decomposes, breaking its chemical bonds and releasing carbon atoms.

- Nucleation: The carbon atoms diffuse and move across the metal surface. They begin to arrange themselves into small islands of the hexagonal graphene lattice, a process known as nucleation.

- Film Growth: These islands grow and eventually merge, forming a continuous, single-atom-thick layer of graphene that can cover the entire surface of the substrate.

Key Variations in CVD Methods

The user's question about different "methods" refers to the specific process conditions used. The choice of method is a strategic decision based on the desired balance between graphene quality, growth temperature, and throughput.

Thermal CVD (TCVD)

This is the most common and straightforward method. The energy required to decompose the precursor gas is supplied entirely by heating the substrate to high temperatures, often around 1000°C. TCVD is known for producing high-quality, single-layer graphene, especially on copper foils.

Plasma-Enhanced CVD (PECVD)

PECVD uses an electrical plasma to help decompose the precursor gases. This creates highly reactive species that can form graphene at much lower temperatures (e.g., 400-600°C). This is a significant advantage when working with substrates that cannot withstand the high temperatures of TCVD.

Low-Pressure CVD (LPCVD) vs. Atmospheric-Pressure CVD (APCVD)

These methods are defined by the pressure inside the reaction chamber.

- LPCVD is performed under a vacuum. This generally leads to higher-purity films with better uniformity because it reduces the chances of contamination from unwanted gas molecules.

- APCVD operates at normal atmospheric pressure. The equipment is simpler and the process can be faster, making it potentially more cost-effective for mass production, though controlling uniformity can be more challenging.

Understanding the Trade-offs

While CVD is the most successful method for large-area graphene synthesis, it is essential to understand its inherent challenges and trade-offs.

The Challenge of Uniformity

Achieving a perfectly uniform, defect-free single layer of graphene over a large area is difficult. The film is polycrystalline, meaning it is composed of many small graphene crystals (grains). The boundaries where these grains meet can degrade the material's electrical and mechanical properties.

The Substrate Transfer Problem

Graphene is grown on a metal catalyst but is typically needed on an insulating substrate like silicon dioxide or a flexible polymer for electronic applications. The process of transferring the delicate, one-atom-thick film from the metal to the target substrate is a major source of defects, wrinkles, and contamination.

Cost and Complexity

High-quality CVD requires specialized equipment with precise control over temperature, pressure, and gas flow. While scalable, the initial investment and operational complexity are significant compared to simpler methods like liquid-phase exfoliation, which produces lower-quality material.

Making the Right Choice for Your Goal

The optimal synthesis method depends entirely on the intended application and desired properties of the final material.

- If your primary focus is fundamental research on pristine graphene: While mechanical exfoliation provides the highest-quality flakes for lab study, precisely controlled Thermal CVD (TCVD) on a single-crystal substrate is the goal for producing large, high-quality films.

- If your primary focus is large-scale industrial electronics: A highly optimized Low-Pressure CVD (LPCVD) process, potentially adapted for a roll-to-roll system, is the only viable path for producing the necessary quality and quantity.

- If your primary focus is creating bulk composites or conductive inks: The lower quality from liquid-phase exfoliation is often sufficient and more cost-effective, making CVD an unnecessary expense.

Ultimately, mastering the CVD process is the cornerstone of translating graphene's extraordinary properties from the laboratory to real-world technology.

Summary Table:

| Method | Key Feature | Typical Use Case |

|---|---|---|

| Thermal CVD (TCVD) | High-temperature heating (~1000°C) | High-quality, single-layer graphene for research |

| Plasma-Enhanced CVD (PECVD) | Lower temperature (400-600°C) via plasma | Growth on temperature-sensitive substrates |

| Low-Pressure CVD (LPCVD) | Operates under vacuum for high purity | Industrial electronics requiring uniform films |

| Atmospheric-Pressure CVD (APCVD) | Simpler, faster process at ambient pressure | Cost-effective mass production |

Ready to integrate high-quality graphene into your research or product development?

The choice of CVD method is critical to achieving the specific material properties your project demands. KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise and reliable graphene synthesis.

Our expertise can help you navigate the trade-offs between quality, cost, and scalability to select the optimal process. Let us support your innovation in materials science.

Contact our experts today to discuss your graphene synthesis needs and how KINTEK's solutions can accelerate your success.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition