The primary methods for sludge disposal are landfilling, incineration, and land application. Each serves as a final step for the residual solids produced during wastewater treatment, but they differ dramatically in cost, environmental impact, and regulatory complexity. The selection of a method is less about the disposal technique itself and more about the quality of the sludge after treatment, local regulations, and long-term sustainability goals.

The challenge of sludge management is not simply "disposal" but a strategic decision between treating it as a waste to be buried, a fuel to be burned, or a resource to be recycled. The right choice depends entirely on a facility's technical capabilities, financial constraints, and environmental priorities.

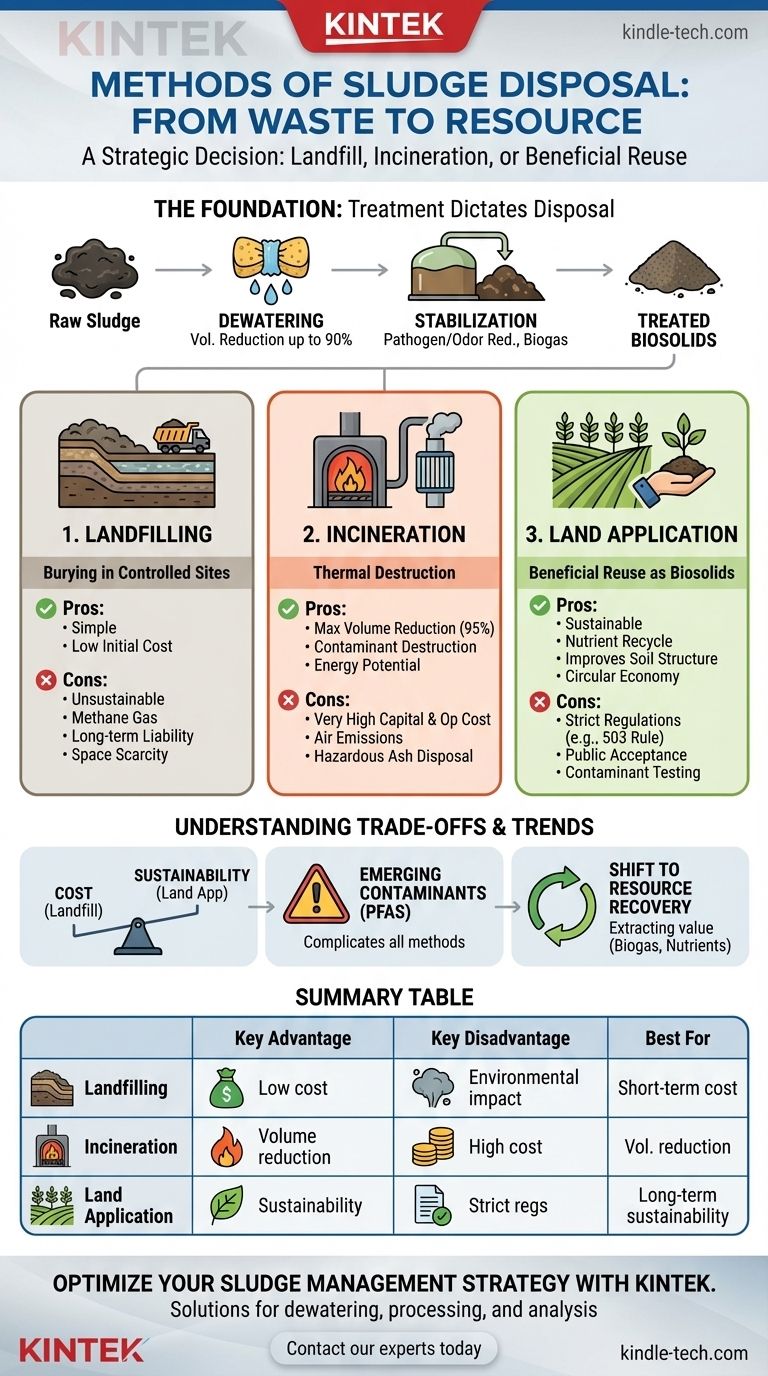

The Foundation: Treatment Dictates Disposal

Before any sludge can be disposed of, it must undergo significant treatment. The characteristics of the final treated sludge, known as biosolids in many cases, are what determine the viability of each disposal option.

Sludge Characteristics

Sludge is primarily water, with a small fraction of organic and inorganic solids. It also contains valuable nutrients like nitrogen and phosphorus, but can harbor pathogens and contaminants such as heavy metals or chemicals like PFAS.

The Critical Role of Dewatering

The single most important initial step is dewatering. Removing water reduces the sludge volume by up to 80-90%, which drastically cuts transportation and disposal costs, regardless of the final method chosen. This is analogous to squeezing water from a sponge before trying to move it.

Stabilization and Pathogen Reduction

Processes like anaerobic digestion or composting stabilize the sludge. This reduces odors, destroys pathogens, and decreases the total volume of solids. Digestion also produces valuable biogas, marking the first step in shifting from a disposal mindset to one of resource recovery.

Disposal Method 1: Landfilling

Landfilling is the practice of burying sludge in a designated and controlled site. It has historically been the most common method due to its simplicity.

How It Works

Dewatered sludge is transported to a municipal solid waste landfill, where it is mixed with other garbage, or to a "monofill" dedicated exclusively to sludge. The site must have systems to manage leachate (contaminated water) and landfill gas.

Key Advantage

The primary advantage is operational simplicity. If a permitted landfill with available capacity is located nearby, it can be a straightforward and relatively low-cost option.

Significant Disadvantages

This method is becoming less sustainable. Landfills produce methane, a potent greenhouse gas, and create long-term environmental liability from potential leachate contamination. Furthermore, landfill space is increasingly scarce and expensive.

Disposal Method 2: Incineration

Incineration is a thermal destruction process that reduces sludge to an inert ash. It is a high-tech solution focused on achieving maximum volume reduction.

The Process

Dewatered sludge is burned in a controlled furnace at very high temperatures. The process is often self-sustaining if the sludge is dry enough, and modern facilities can recover heat to generate steam or electricity.

Key Advantages

Incineration achieves the greatest volume reduction (up to 95%), completely destroys pathogens and organic contaminants, and offers the potential for energy recovery. The resulting ash is a small, stable volume.

Significant Disadvantages

The capital and operational costs are extremely high. The process requires complex and expensive air pollution control systems to manage emissions, and the residual ash must still be landfilled. This ash can have high concentrations of heavy metals, sometimes classifying it as hazardous waste.

Disposal Method 3: Land Application (Beneficial Reuse)

This approach reframes high-quality treated sludge, now called biosolids, as a valuable product rather than a waste. It focuses on recycling the organic matter and nutrients back into the ecosystem.

Application in Agriculture

The most common form of beneficial reuse is applying biosolids to agricultural land. It acts as a slow-release fertilizer and soil conditioner, improving soil structure and reducing the need for chemical fertilizers.

Land Reclamation

Biosolids are also used to revegetate and restore land damaged by mining, construction, or erosion. The organic matter and nutrients help establish a sustainable soil profile where little else will grow.

Strict Regulatory Control

Land application is governed by strict regulatory frameworks, such as the U.S. EPA's "503 Rule." These rules set rigorous limits on pathogen levels, heavy metals, and application rates to ensure the practice is safe for human health and the environment.

Understanding the Trade-offs

Choosing a disposal method involves navigating a complex set of competing factors. No single solution is perfect for every situation.

The Cost vs. Sustainability Matrix

Landfilling is often the cheapest short-term option but is environmentally unsustainable. Incineration offers maximum destruction but at a very high financial and energy cost. Land application is the most sustainable, circular-economy approach but requires rigorous quality control and public acceptance.

The Problem of Emerging Contaminants

Contaminants like PFAS ("forever chemicals") are a major emerging challenge. These chemicals can pass through conventional treatment and concentrate in sludge, complicating both land application and, to a lesser extent, incineration and landfilling, as regulations tighten.

The Shift Towards Resource Recovery

The most advanced approach is to move beyond "disposal" entirely. Modern facilities focus on a "resource recovery" model, where they aim to extract maximum value from the sludge—recovering phosphorus for fertilizer, producing biogas for energy, and creating high-quality biosolids for soil amendment.

Selecting the Right Strategy for Your Goal

Your final decision must be aligned with your operational, financial, and environmental objectives.

- If your primary focus is lowest initial cost and simplicity: Landfilling is the most direct route, but be prepared for rising fees and long-term environmental liabilities.

- If your primary focus is maximum volume reduction and destroying contaminants: Incineration is the most robust technical solution, provided you can justify the significant capital investment and operational complexity.

- If your primary focus is sustainability and resource recovery: Land application of high-quality biosolids is the ideal path, but it demands excellent pre-treatment, rigorous testing, and strict regulatory compliance.

Ultimately, the future of sludge management lies in viewing it not as a waste to be discarded, but as a raw material rich with potential value.

Summary Table:

| Method | Key Advantage | Key Disadvantage | Best For |

|---|---|---|---|

| Landfilling | Low initial cost, operational simplicity | High environmental impact, long-term liability | Short-term, cost-focused solutions |

| Incineration | Maximum volume reduction, destroys contaminants | Very high capital and operational costs | Volume reduction, contaminant destruction |

| Land Application | Sustainable, recycles nutrients, improves soil | Requires rigorous quality control and testing | Long-term sustainability and resource recovery |

Optimize Your Sludge Management Strategy with KINTEK

Navigating the complexities of sludge disposal—from dewatering and stabilization to final disposal—requires robust and reliable equipment. Whether your goal is efficient dewatering for cost-effective landfilling, precise thermal processing for incineration, or producing high-quality biosolids for land application, KINTEK has the solutions.

We specialize in providing high-performance lab equipment and consumables that support the entire sludge treatment lifecycle. Our products help you analyze sludge composition, optimize dewatering processes, and ensure compliance with stringent regulatory standards.

Ready to transform your sludge from a waste burden into a managed resource?

Contact our experts today to discuss how KINTEK's equipment can enhance your sludge management efficiency, reduce costs, and support your sustainability goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Graphite Vacuum Furnace Bottom Discharge Graphitization Furnace for Carbon Materials

- Wall Mounted Water Distillation Unit

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs