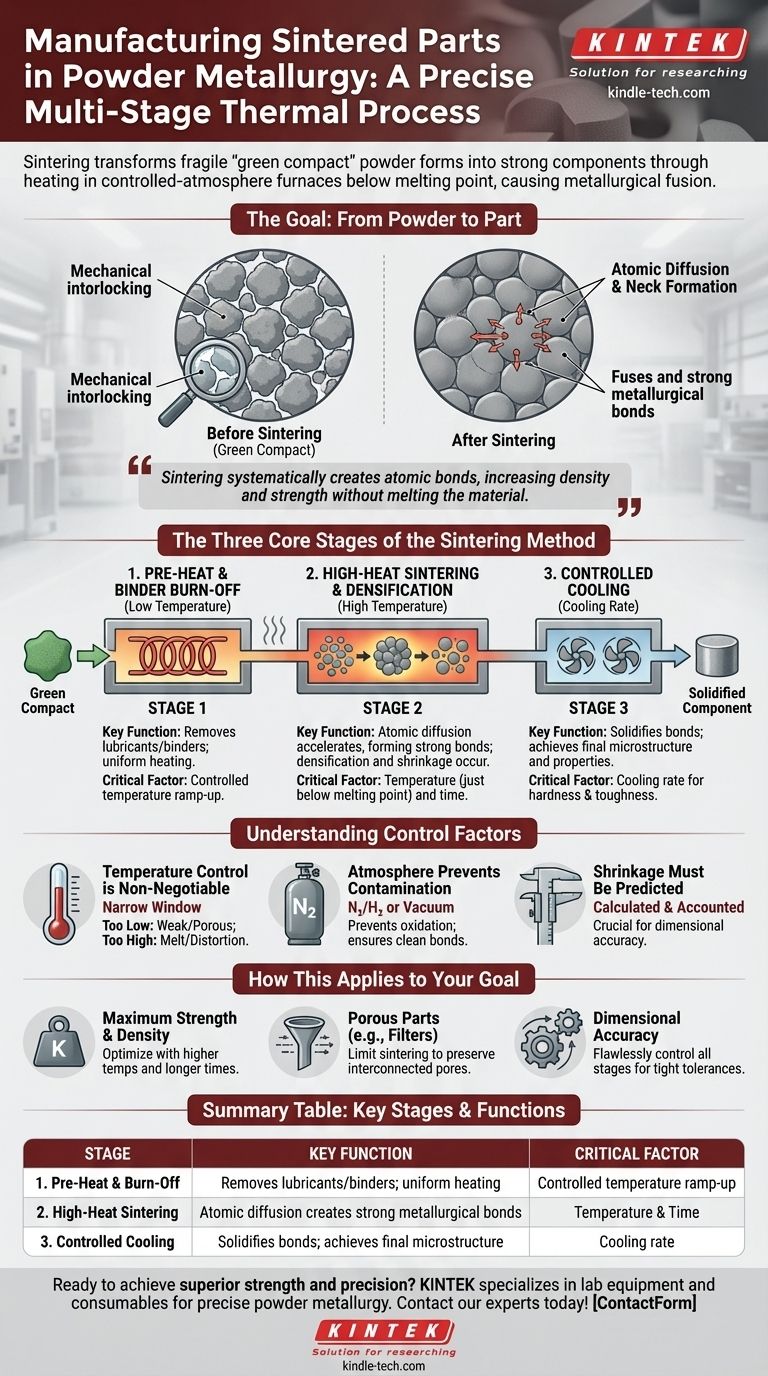

In powder metallurgy, sintering is not a single action but a precise, multi-stage thermal process. It transforms a fragile, compacted metal powder form—known as a "green compact"—into a strong, structurally sound component by heating it in a controlled-atmosphere furnace to a temperature just below the primary metal's melting point. This heat causes the individual powder particles to metallurgically fuse together, creating a solid mass.

The core method of sintering is a carefully controlled journey through distinct temperature zones in a furnace. This process systematically creates atomic bonds between powder particles, increasing the part's density and strength without ever melting the material.

The Goal of Sintering: From Powder to Part

The fundamental purpose of sintering is to impart strength and integrity to a compacted powder part. Before sintering, the component is held together only by the mechanical interlocking of the pressed particles and is quite brittle.

The Mechanism of Bonding

Think of how ice cubes in a glass of water will begin to fuse together at their points of contact. Sintering works on a similar principle, but at a microscopic level through a process called atomic diffusion.

At high temperatures, atoms from adjacent particles migrate across the boundaries, forming "necks" at the contact points. These necks grow over time, pulling the particles closer, reducing pore space, and creating strong metallurgical bonds.

A Journey, Not an Event

The sintering process is conducted in a long, continuous furnace with different temperature zones. This allows for precise control over the heating and cooling cycle, which is essential for achieving the desired final properties of the component.

The Three Core Stages of the Sintering Method

The manufacturing method can be broken down into three critical stages that occur as the part travels through the furnace.

Stage 1: Pre-Heat and Binder Burn-Off

As the green compact enters the furnace, it first goes through a lower-temperature pre-heating zone. The primary goal here is to slowly and uniformly raise the part's temperature.

This initial stage also serves to burn off any lubricants or binding agents that were mixed with the powder to aid in the compaction process. Removing these volatile materials properly is crucial to prevent defects in the final part.

Stage 2: High-Heat Sintering and Densification

Next, the part moves into the high-heat zone, where the actual sintering takes place. The temperature is held just below the melting point of the main metallic constituent.

During this stage, atomic diffusion accelerates dramatically. The "necks" between particles grow significantly, causing the part to densify and shrink as the pores between particles get smaller. The duration and temperature in this zone are the most critical factors determining the final strength and density.

Stage 3: Controlled Cooling

Finally, the part moves into a cooling zone. The rate of cooling is carefully controlled to solidify the newly formed metallurgical bonds and achieve the desired final microstructure, which dictates properties like hardness and toughness. Cooling too quickly or too slowly can introduce internal stresses or result in a brittle part.

Understanding the Trade-offs and Control Factors

Achieving a successful outcome with sintering requires balancing several competing factors. Mismanagement of any variable can compromise the entire process.

Temperature Control is Non-Negotiable

The sintering temperature "window" is often very narrow. If the temperature is too low, bonding will be incomplete, resulting in a weak and porous part. If it's too high, the material can begin to melt, causing the part to distort, lose its shape, and lose its precise dimensions.

Atmosphere Prevents Contamination

Sintering is almost always done in a tightly controlled atmosphere, such as a nitrogen/hydrogen mix or a vacuum. At high temperatures, most metals will rapidly oxidize if exposed to oxygen. A controlled atmosphere prevents this oxidation and removes existing oxides, ensuring clean, strong bonds between particles.

Shrinkage Must Be Predicted

The increase in density during sintering is accompanied by a predictable amount of shrinkage. This must be precisely calculated and accounted for when designing the initial tooling and the green compact. Failure to do so will result in a final part that is outside of dimensional tolerances.

How This Applies to Your Goal

Understanding the sintering method allows engineers to specify materials and processes to meet specific component requirements.

- If your primary focus is maximum strength and density: The process must be optimized with higher temperatures and longer times in the high-heat zone to minimize porosity.

- If your primary focus is creating a porous part (e.g., for filters or self-lubricating bearings): The sintering process is intentionally limited to create strong bonds while preserving a network of interconnected pores.

- If your primary focus is dimensional accuracy: Every stage, from powder mixing to cooling, must be flawlessly controlled to manage shrinkage and ensure the final part meets tight tolerances.

Ultimately, mastering the sintering method is what unlocks the unique capabilities of powder metallurgy to create complex, net-shape parts efficiently.

Summary Table:

| Stage | Key Function | Critical Factor |

|---|---|---|

| 1. Pre-Heat & Burn-Off | Removes lubricants/binders; uniform heating. | Controlled temperature ramp-up. |

| 2. High-Heat Sintering | Atomic diffusion creates strong metallurgical bonds. | Temperature (just below melting point) and time. |

| 3. Controlled Cooling | Solidifies bonds; achieves final microstructure. | Cooling rate to control properties like hardness. |

Ready to achieve superior strength and precision in your sintered components? The sintering process is critical to your final part's performance. KINTEK specializes in the lab equipment and consumables that support precise powder metallurgy, from furnace atmospheres to temperature control. Let our experts help you optimize your sintering method for maximum density, strength, or dimensional accuracy. Contact our team today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is sintering reaction? Transform Powders into Dense Solids Without Melting

- What are the factors influencing shrinkage during sintering? Control Dimensional Changes for Precision Parts

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- Why is a high vacuum required for sintering Ti-43Al-4Nb-1Mo-0.1B? Ensure Purity & Fracture Toughness

- What is vacuum sintering? Achieve Unmatched Purity and Performance for Advanced Materials