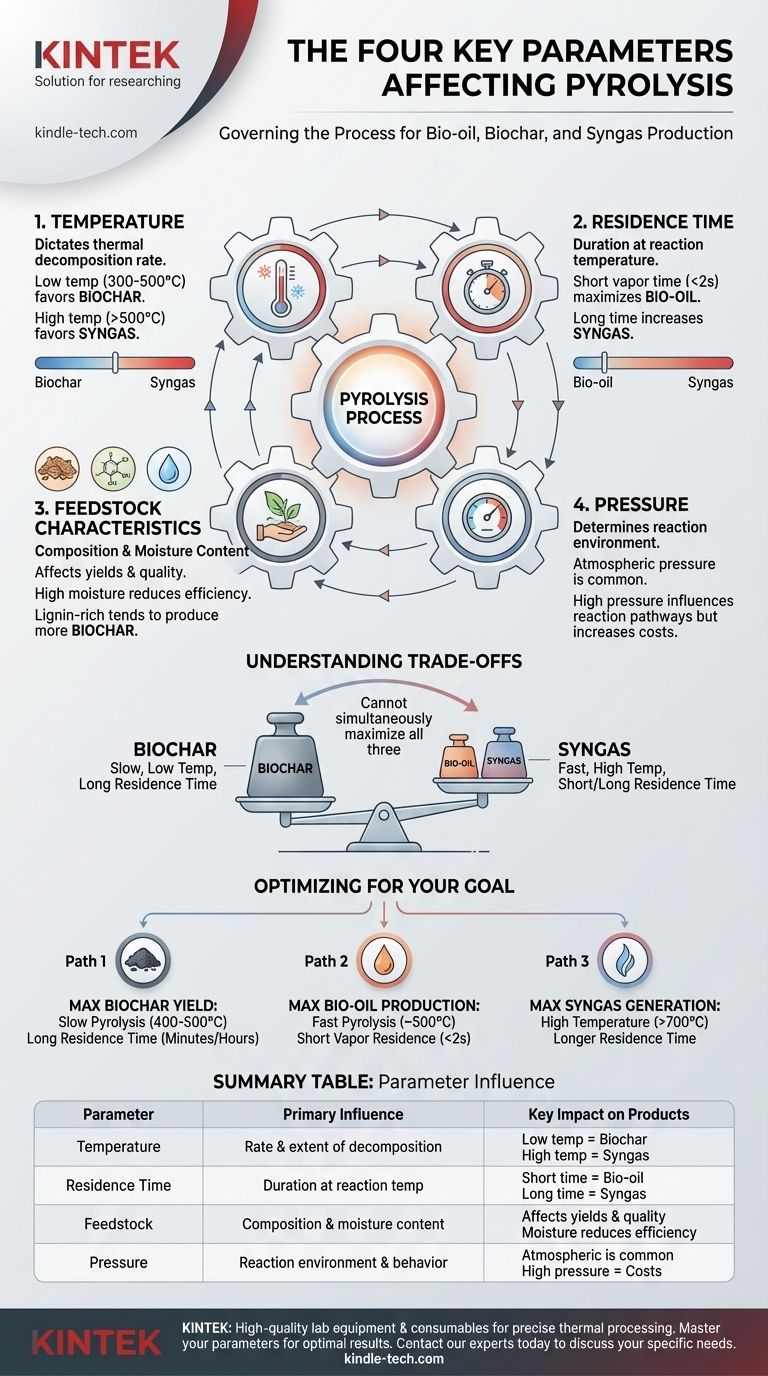

In short, the pyrolysis process is governed by four key parameters. These are the reaction temperature, the residence time of the material, the characteristics of the feedstock (such as type and moisture content), and the operating pressure. The precise manipulation of these factors determines not only the efficiency of the conversion but also the final distribution of products like bio-oil, biochar, and syngas.

Understanding pyrolysis is not about knowing the parameters, but about understanding how they function as interconnected levers. Adjusting one inevitably affects the others, and mastering this interplay is the key to controlling the output for a specific goal.

The Core Levers of Pyrolysis Control

To effectively control a pyrolysis reactor, you must understand how each primary parameter influences the chemical transformations taking place. They do not operate in isolation.

The Role of Temperature

Temperature is arguably the most critical parameter in pyrolysis as it dictates the rate and extent of thermal decomposition.

Lower temperatures (around 300-500°C) favor slower reactions. This condition maximizes the production of a solid residue, known as biochar.

Higher temperatures (above 500-600°C) promote the breakdown of larger vapor molecules into smaller, non-condensable gases. This increases the yield of syngas.

The Impact of Residence Time

Residence time refers to how long the feedstock and its derived vapors remain at the reaction temperature. It works in concert with temperature to define the final product slate.

A very short vapor residence time (typically less than 2 seconds) is crucial for preserving the complex molecules that form bio-oil. Vapors are removed from the hot zone and cooled rapidly to prevent further reactions.

Longer residence times allow for secondary cracking, where the initial vapor products are further broken down into lower molecular weight gases, increasing the syngas yield at the expense of bio-oil.

The Influence of Feedstock Characteristics

The process begins with the feedstock, and its initial state has a profound impact on the outcome. The two most important characteristics are its chemical composition and moisture content.

The composition of the biomass (e.g., the ratio of cellulose, hemicellulose, and lignin) directly influences the product yields. For example, lignin-rich feedstocks tend to produce more biochar and phenolic compounds in the bio-oil.

Moisture content is a critical practical consideration. Energy must first be spent to evaporate water, reducing the overall thermal efficiency of the process. High moisture can also lead to a lower-quality, water-rich bio-oil.

The Effect of Pressure

Pressure determines the environment in which the reactions occur, affecting vapor behavior.

Most pyrolysis operations are conducted at or near atmospheric pressure for simplicity and cost-effectiveness.

Increasing the pressure can influence reaction pathways and enhance heat transfer. However, it significantly increases the capital and operating costs of the system, making it less common for typical biomass applications.

Understanding the Trade-offs

Optimizing pyrolysis is a balancing act. Improving the yield of one product often comes at the direct expense of another. Recognizing these trade-offs is essential for practical application.

Char vs. Oil vs. Gas: The Fundamental Conflict

You cannot simultaneously maximize all three primary products.

The slow, low-temperature conditions that favor high biochar yield inherently produce less bio-oil and syngas. Conversely, the fast, high-temperature conditions needed for syngas will thermally crack the valuable compounds that form bio-oil and leave behind less char.

Throughput vs. Product Quality

There is often a trade-off between the rate of processing and the quality of the desired product.

For instance, extremely rapid heating can maximize bio-oil yield but may result in a less stable product containing more aerosols and undesirable compounds. Slower, more controlled heating might produce a higher-quality, more stable biochar.

Upfront Cost vs. Process Efficiency

The primary example of this is feedstock preparation, particularly drying.

Drying biomass before pyrolysis requires a significant initial investment in equipment and energy. However, processing wet feedstock is thermally inefficient and yields a lower-quality liquid product, increasing downstream processing costs.

Optimizing Parameters for Your Desired Product

Your operational strategy must be dictated by your end goal. Set the process parameters based on the product you value most.

- If your primary focus is maximizing biochar yield: Employ slow pyrolysis with lower temperatures (400-500°C) and long solid residence times (minutes to hours).

- If your primary focus is maximizing bio-oil production: Use fast pyrolysis with moderate temperatures (around 500°C), extremely short vapor residence times (<2 seconds), and rapid quenching of the vapors.

- If your primary focus is generating syngas: Operate at high temperatures (>700°C) with longer residence times to encourage the thermal cracking of all vapors into permanent gases.

Mastering these parameters transforms pyrolysis from a brute-force heating process into a precise tool for creating valuable, tailored products from biomass.

Summary Table:

| Parameter | Primary Influence on Pyrolysis | Key Impact on Products |

|---|---|---|

| Temperature | Rate and extent of thermal decomposition | Low temp (300-500°C) favors biochar; High temp (>500°C) favors syngas |

| Residence Time | Duration of feedstock/vapors at reaction temperature | Short time (<2s) maximizes bio-oil; Long time increases syngas |

| Feedstock | Composition and moisture content of biomass | Affects yields and quality; High moisture reduces efficiency |

| Pressure | Reaction environment and vapor behavior | Atmospheric pressure is common; High pressure increases costs |

Ready to optimize your pyrolysis process for maximum efficiency and tailored product yields? KINTEK specializes in high-quality lab equipment and consumables for precise thermal processing. Whether you're focused on bio-oil, biochar, or syngas production, our solutions help you master temperature control, residence time, and feedstock handling. Contact our experts today to discuss how we can support your laboratory's specific pyrolysis needs and enhance your research outcomes.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

People Also Ask

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- What is the function of alumina tubes and alumina wool in a pyrolysis furnace? Optimize Your Biochar Production Quality

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab