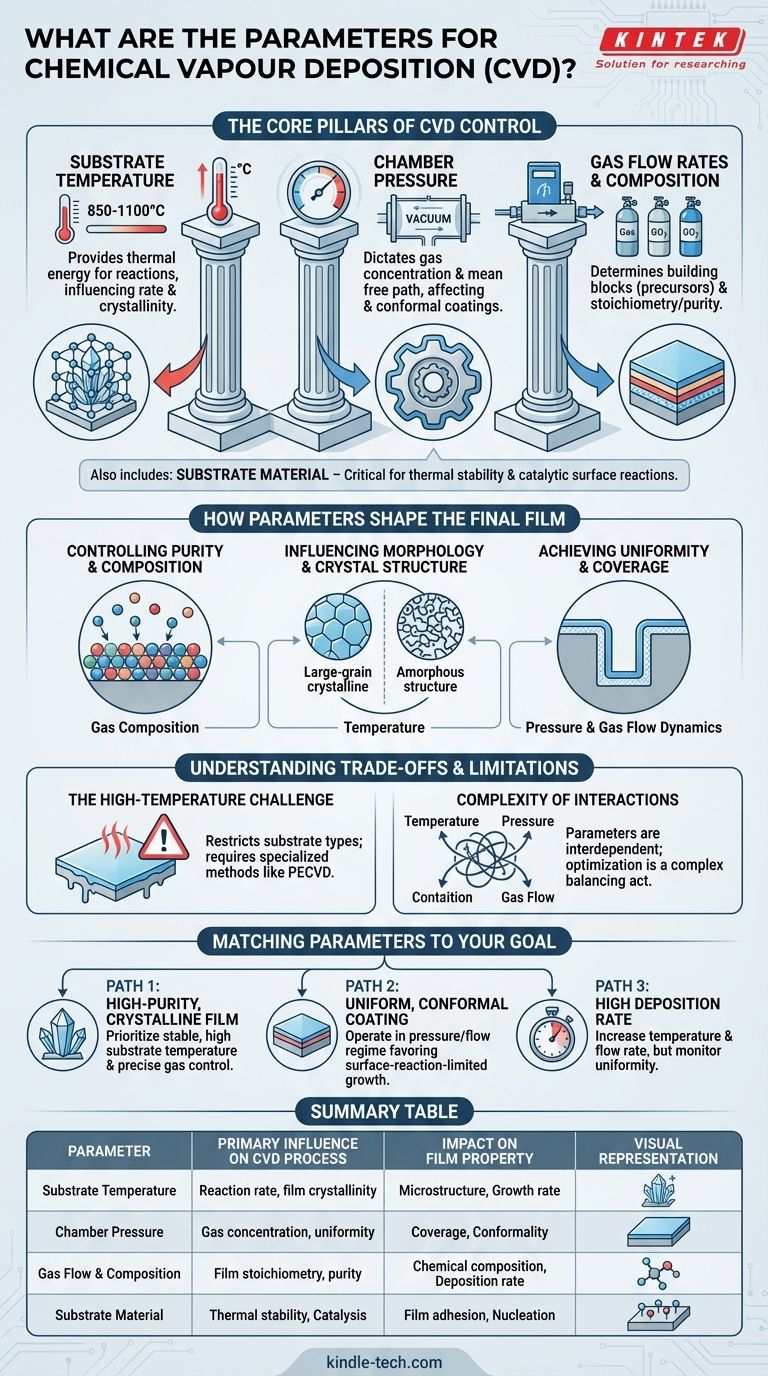

The primary parameters for Chemical Vapor Deposition (CVD) are substrate temperature, chamber pressure, and the flow rates and composition of the reactant gases. These variables are precisely controlled to manage the chemical reactions that result in the deposition of a high-quality thin film onto a substrate surface.

At its core, controlling a CVD process is not about setting a single parameter, but about understanding and balancing the interplay between temperature, pressure, and gas chemistry. Mastering this balance is what allows for the precise engineering of a film's properties, from its chemical composition to its crystal structure.

The Core Pillars of CVD Control

To understand how to achieve a desired outcome with CVD, you must first grasp the fundamental levers you can pull. Each parameter directly influences the distinct stages of the deposition process, including reactant transport, surface reaction, and byproduct removal.

Substrate Temperature

Temperature is arguably the most critical parameter in CVD. It provides the thermal energy needed to initiate and sustain the chemical reactions on the substrate's surface.

The chosen temperature directly influences reaction rates, the crystal structure (crystallinity) of the deposited film, and the diffusion of atoms on the surface. As noted in process limitations, conventional CVD often requires very high temperatures, typically between 850-1100°C.

Chamber Pressure

The pressure inside the CVD reactor dictates the concentration and mean free path of the gas molecules. This has a profound effect on the deposition mechanism and the resulting film quality.

Lower pressures can increase gas diffusivity, leading to more uniform coatings, while higher pressures can increase deposition rates. The pressure regime is a key factor in achieving conformal coatings on complex, non-line-of-sight surfaces.

Gas Flow Rates & Composition

The specific gases used (precursors) and their flow rates determine the building blocks available for the film. The composition, or the ratio of different reactant gases, directly controls the stoichiometry and purity of the final deposit.

Adjusting the flow rate manages the supply of reactants to the surface. Too low a flow can starve the reaction, while too high a flow can lead to inefficient use of precursors and gas-phase reactions away from the substrate.

Substrate Material

While not an adjustable process variable, the substrate itself is a critical parameter. Its material composition must be able to withstand the high process temperatures without degrading.

Furthermore, the substrate surface can play a catalytic role in the chemical reactions, directly influencing nucleation and the initial stages of film growth.

How Parameters Shape the Final Film

The power of CVD comes from its ability to produce a vast range of materials with tailored properties. This is achieved by manipulating the core parameters to influence specific characteristics of the film.

Controlling Purity and Composition

The chemical makeup of the deposited film is primarily controlled by the gas composition. By introducing specific precursor gases in precise ratios, one can create multi-component alloys, compounds, and ceramic layers with high purity.

Influencing Morphology and Crystal Structure

Temperature is the dominant factor in determining the film's microstructure. Higher temperatures generally promote the growth of larger, more well-ordered crystalline grains, while lower temperatures may result in amorphous or fine-grained structures.

Achieving Uniformity and Coverage

Achieving an even coating, especially on complex shapes, relies on a balance of pressure and gas flow dynamics. This ensures that reactant gases can diffuse and adsorb evenly across the entire surface area, a key advantage of the CVD method.

Understanding the Trade-offs and Limitations

While powerful, the CVD process is governed by a set of trade-offs and constraints that are critical to understand for successful implementation.

The High-Temperature Challenge

The most significant limitation of many CVD processes is the high reaction temperature. This requirement restricts the types of substrate materials that can be used, as many materials cannot withstand such thermal loads without melting, warping, or degrading.

Techniques like plasma-enhanced or laser-assisted CVD have been developed specifically to lower this required deposition temperature, broadening the range of applicable substrates.

Complexity of Interactions

The process parameters are not independent variables. A change in temperature will affect the optimal pressure; an adjustment in gas flow may require a new temperature setpoint. This interdependence means that process optimization is a complex balancing act, not a simple, linear adjustment.

Matching Parameters to Your Goal

The ideal settings for your CVD process depend entirely on your objective. Use these principles as a starting guide for process development.

- If your primary focus is a high-purity, crystalline film: Prioritize stable, high substrate temperatures and precise, consistent control over gas composition and purity.

- If your primary focus is a uniform, conformal coating on a complex part: Operate in a pressure regime and gas flow that favors surface-reaction-limited growth, ensuring reactants reach all surfaces before reacting.

- If your primary focus is a high deposition rate: You will likely need to increase both the substrate temperature and the flow rate of reactant gases, but be prepared to monitor for potential decreases in film uniformity or quality.

By understanding these parameters, you transform CVD from a complex chemical process into a highly controllable and precise manufacturing tool.

Summary Table:

| Parameter | Primary Influence on CVD Process |

|---|---|

| Substrate Temperature | Reaction rate, film crystallinity, and microstructure |

| Chamber Pressure | Gas concentration, uniformity, and conformal coverage |

| Gas Flow & Composition | Film stoichiometry, purity, and deposition rate |

| Substrate Material | Thermal stability and catalytic surface reactions |

Ready to Optimize Your CVD Process?

Mastering the balance of temperature, pressure, and gas chemistry is key to producing high-performance thin films. KINTEK specializes in providing the precise lab equipment and consumables needed to control these critical CVD parameters effectively.

Whether you are developing new materials or scaling up production, our expertise can help you achieve superior film quality, uniformity, and purity. Contact our experts today via our form to discuss how we can support your laboratory's specific CVD needs and enhance your research and development outcomes.

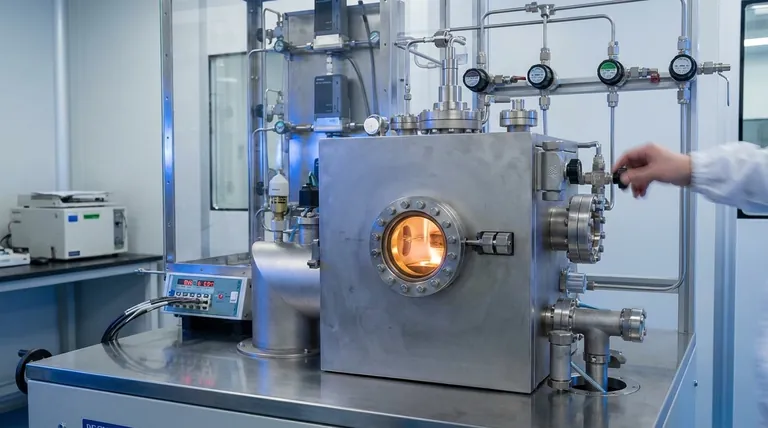

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate