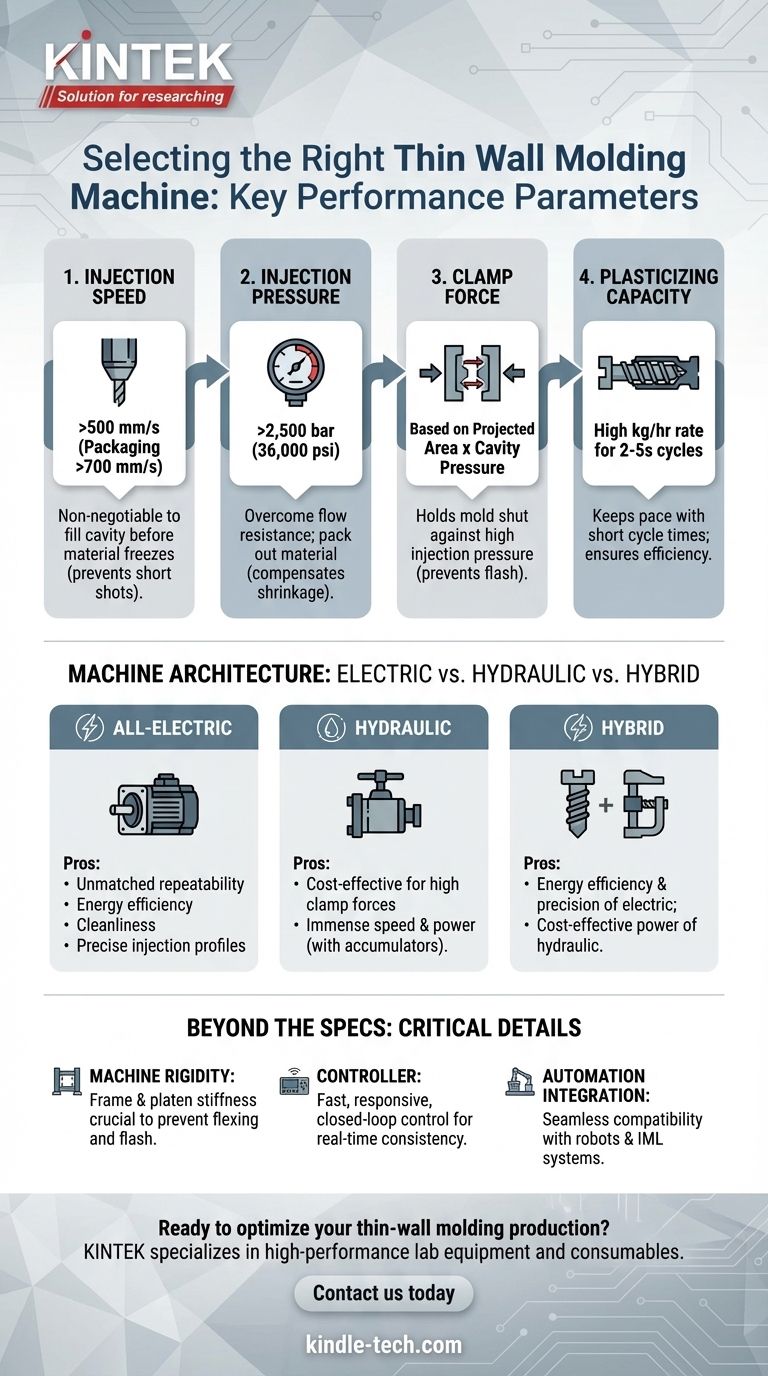

To select the right thin wall molding machine, you must prioritize four key performance parameters: injection speed, injection pressure, plasticizing capacity, and clamp force. These specifications are not independent; they must work in concert to overcome the fundamental challenge of thin wall molding, which is filling the mold cavity completely and consistently before the molten plastic freezes. A machine lacking in any one of these areas will fail to produce quality parts reliably at a competitive cycle time.

The core objective is not simply to buy a machine with high specifications, but to select an integrated system that delivers extreme precision and repeatability. The right machine minimizes cycle time and ensures process stability, which are the cornerstones of profitability in high-volume thin-wall production.

The Core Pillars of Thin-Wall Performance

The physics of thin-wall molding—forcing molten polymer through a very narrow cross-section—places extreme demands on the injection molding machine. Understanding these demands is the key to making an informed choice.

Injection Speed: The Non-Negotiable Requirement

Thin-wall applications require exceptionally high injection speeds, often exceeding 500 mm/s, with specialized packaging applications demanding 700 mm/s or more.

This speed is critical to fill the mold cavity before the material solidifies, a phenomenon known as a "short shot." The thin cross-section of the part causes the molten plastic to cool and freeze almost instantly upon contact with the cooler mold surface.

To achieve this, high-performance hydraulic machines rely on accumulators, which store hydraulic pressure to deliver an explosive burst of speed. Modern all-electric machines achieve this through high-power servo motors, offering superior control and acceleration.

Injection Pressure: Overcoming Flow Resistance

The narrow flow path of a thin-walled part creates immense resistance. The machine must have sufficient injection pressure—often in excess of 2,500 bar (36,000 psi)—to overcome this resistance.

This high pressure is necessary not only to fill the part but also to pack it out effectively, compensating for material shrinkage as it cools. Inadequate pressure capability will result in sinks, voids, and dimensional instability.

Clamp Force: Holding the Mold Shut

High injection pressures generate an equal and opposite force that tries to push the two halves of the mold apart. The machine's clamp unit must provide enough force to hold the mold shut against this pressure.

The required clamp force is calculated by multiplying the part's total projected area (including the runner system) by the peak injection pressure inside the cavity. A machine with insufficient clamp force will allow the mold to open slightly, creating flash (excess plastic leaking from the parting line).

Equally important is the rigidity of the platens. Even with adequate clamp force, platens that flex under pressure will cause flash and inconsistent part quality.

Plasticizing Capacity: Keeping Pace with Short Cycles

Thin-wall molding is defined by extremely short cycle times, often between 2 and 5 seconds. The machine's screw and barrel system must be able to melt enough plastic resin for the next shot within this brief recovery time.

This is known as the plasticizing rate, measured in kg/hr or lbs/hr. A machine with inadequate plasticizing capacity cannot keep up, forcing you to extend the cycle time and destroying your production efficiency. Look for machines with a screw designed for high throughput and a powerful screw drive motor.

Machine Architecture: Electric vs. Hydraulic

The choice between an all-electric, hydraulic, or hybrid machine is a central decision driven by your specific application and priorities.

The Case for All-Electric Machines

All-electric machines use high-precision servo motors for all movements. Their primary advantages are unmatched repeatability, energy efficiency, and cleanliness.

The digital control over every axis allows for precise injection profiles and parallel functions (e.g., ejecting parts while the clamp is opening), which can significantly reduce cycle times. Their quiet, clean operation makes them ideal for medical and food-grade packaging.

The Role of High-Performance Hydraulic Machines

Hydraulic machines, particularly those equipped with accumulators, are workhorses known for delivering immense injection speed and power. They can be a more cost-effective solution for applications requiring very high clamping forces.

While they may not offer the same level of micro-precision as all-electric models, modern hydraulic machines with closed-loop controls provide excellent performance for many high-volume thin-wall applications.

The Hybrid Advantage

Hybrid machines offer a compelling compromise, combining an electric screw drive and injection unit with a hydraulic clamp. This architecture gives you the energy efficiency and precision of electric injection while retaining the cost-effective power of a hydraulic clamp. Hybrids are an increasingly popular choice for thin-wall packaging.

Understanding the Trade-offs and Critical Details

Beyond the four primary specs, several other factors can make or break your thin-wall molding operation.

Beyond the Spec Sheet: Machine Rigidity

A machine's technical datasheet does not tell the full story. The overall rigidity of the machine frame and platens is paramount. A machine that twists or flexes under the high stresses of thin-wall molding will never be stable, leading to flash, dimensional variance, and premature mold wear.

The Controller: The Brain of the Operation

The machine's controller must be fast and responsive enough to manage the process in real time. Millisecond-level changes in pressure and velocity are common. A powerful controller with closed-loop process control is essential for maintaining consistency shot after shot.

Integration with Automation

Thin-wall production is almost always automated. The machine must be designed for seamless integration with robots for part removal and In-Mold Labeling (IML). Ensure the controller and safety systems are easily compatible with third-party automation.

Making the Right Choice for Your Application

Use your specific production goals to guide your final selection.

- If your primary focus is maximum speed for packaging (e.g., containers, lids): Prioritize a specialized packaging machine (often a hybrid or all-electric) with injection speeds over 700 mm/s and robust parallel functions to minimize cycle time.

- If your primary focus is high-precision medical or electronic parts: Emphasize the process control and shot-to-shot repeatability of an all-electric machine with advanced process monitoring capabilities.

- If you are running large parts with very high clamp force requirements: A high-performance hydraulic machine with accumulators may offer the most cost-effective combination of clamping power and injection performance.

- If your budget is a key constraint for less extreme thin-wall parts: A well-specified general-purpose hydraulic machine, optioned with an accumulator package for high-speed injection, can be a viable and effective solution.

Ultimately, selecting the right machine is a system-level decision that balances speed, precision, and cost to ensure profitable and reliable production.

Summary Table:

| Parameter | Key Consideration | Typical Range |

|---|---|---|

| Injection Speed | Must fill cavity before plastic solidifies | >500 mm/s, up to 700+ mm/s |

| Injection Pressure | Overcomes flow resistance in narrow cavities | >2,500 bar (36,000 psi) |

| Clamp Force | Holds mold shut against high injection pressure | Based on projected area x cavity pressure |

| Plasticizing Capacity | Melts enough resin for short cycle times | High kg/hr rate for 2-5 second cycles |

Ready to optimize your thin-wall molding production? KINTEK specializes in high-performance lab equipment and consumables, serving laboratories with precision molding solutions. Our experts can help you select the perfect machine to maximize speed, precision, and profitability. Contact us today to discuss your specific thin-wall application requirements!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Double Plate Heating Press Mold for Lab

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- What are the safety rules when using a hydraulic press? Essential Guidelines for Secure Operation

- Which forging press would be best for producing very large parts? Unmatched Force for Massive Components

- What is the purpose of using a laboratory hydraulic press in the preparation of unit cells? Enhance Data Integrity.

- What happens if hydraulic pressure is too high? Prevent Catastrophic System Failure and Downtime

- What is the function of a bench-top laboratory hydraulic press for XRF? Maximize Accuracy in Prosopis juliflora Analysis

- What are the technical advantages of using a manual hydraulic press with carbide dies? Achieve High-Density Green Bodies

- Is forging a shaping process? Discover How It Enhances Material Strength and Durability

- How does a laboratory hydraulic press contribute to the low-temperature densification of NaSICON electrolytes? Master CSP