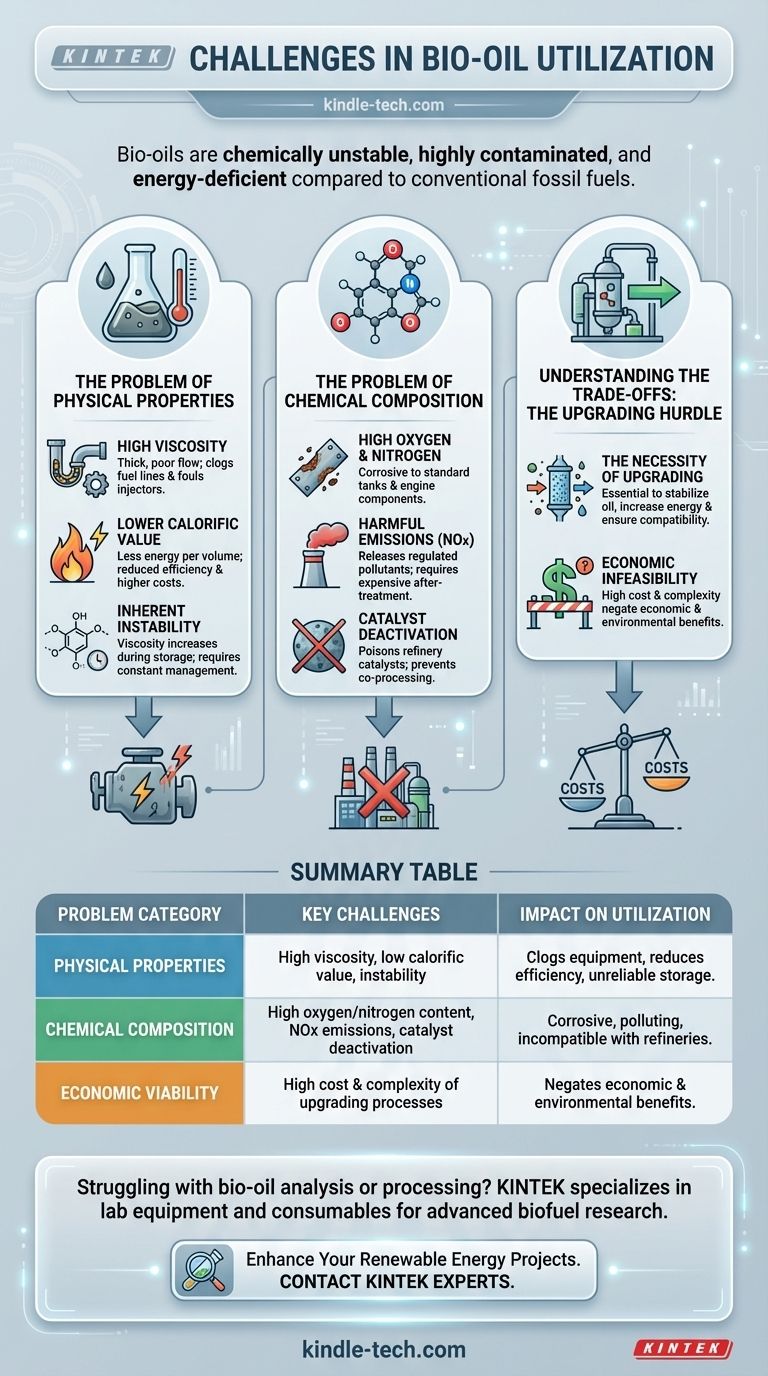

The fundamental problem with utilizing bio-oils is that they are chemically unstable, highly contaminated, and energy-deficient compared to conventional fossil fuels. This raw state makes them incompatible with our existing engines and refinery infrastructure without significant and costly pre-treatment, often called "upgrading."

While bio-oil is a renewable resource, its inherent chemical properties—high viscosity, low energy value, and corrosive contaminants like nitrogen and oxygen—create significant technical and economic barriers to its widespread adoption as a direct replacement for petroleum.

The Problem of Physical Properties

The physical characteristics of raw bio-oil present immediate, practical challenges for storage, transport, and use. These properties differ significantly from the refined fuels our systems are designed for.

High Viscosity

Bio-oil is often thick and flows poorly, especially at lower temperatures. This high viscosity can clog fuel lines, foul injectors, and require specialized, high-energy pumps, complicating its use in standard engines and equipment.

Lower Calorific Value

Compared to an equivalent volume of fossil fuel, bio-oil contains less energy. This lower energy density means more fuel is required to produce the same amount of power, which impacts efficiency, storage requirements, and overall cost-effectiveness.

Inherent Instability

Bio-oil is chemically unstable and can deteriorate over time. During storage, its viscosity can increase, and it can separate into different phases, making it a highly unreliable fuel source without ongoing management or rapid use.

The Problem of Chemical Composition

The chemical makeup of bio-oil is the root cause of its most difficult challenges. It is a complex mixture containing high levels of oxygen and, depending on the source, nitrogen, which act as powerful contaminants.

High Oxygen and Nitrogen Content

The presence of oxygen makes bio-oil acidic and corrosive to standard tanks, pipes, and engine components. Algal bio-oils, in particular, have a high nitrogen content, which creates further problems in both refining and combustion.

Harmful Emissions (NOx)

When bio-oil with high nitrogen content is burned, it releases nitrogen oxides (NOx). These are potent air pollutants and greenhouse gases that are strictly regulated, requiring expensive after-treatment systems for emission control.

Catalyst Deactivation in Refineries

Existing oil refineries rely on expensive, long-lasting catalysts to process crude oil. The oxygen and nitrogen in bio-oil act as poisons, rapidly deactivating these catalysts. This makes it impossible to "co-process" bio-oil alongside conventional crude oil without a dedicated and costly upgrading step first.

Understanding the Trade-offs: The Upgrading Hurdle

The solution to bio-oil's chemical and physical flaws is a process called upgrading. However, this process introduces its own significant challenges, primarily centered on cost and complexity.

The Necessity of Upgrading

Upgrading is a form of pre-refining that aims to remove the problematic oxygen and nitrogen atoms. This step is essential to stabilize the oil, increase its energy value, and make it compatible with conventional refinery equipment.

Economic Infeasibility

Current upgrading and purification technologies are not yet mature or economically viable at a large scale. The energy and resources required to upgrade bio-oil to a "drop-in" fuel often negate the economic and environmental benefits of using it in the first place.

How to Approach Bio-Oil Utilization

The viability of bio-oil is entirely dependent on the intended application, as each use case is affected differently by its inherent flaws.

- If your primary focus is direct combustion for stationary heat or power: Your main challenges are the lower energy value, potential equipment corrosion, and managing NOx emissions.

- If your primary focus is creating a "drop-in" transportation fuel: The need for intensive, multi-stage upgrading to remove contaminants and improve stability is the single largest technical and economic barrier.

- If your primary focus is extracting high-value chemicals: The primary obstacle is the lack of mature and cost-effective technologies to separate and purify target compounds from the complex bio-oil mixture.

Ultimately, unlocking the potential of bio-oil hinges on the development of efficient and economical upgrading and refining technologies.

Summary Table:

| Problem Category | Key Challenges | Impact on Utilization |

|---|---|---|

| Physical Properties | High viscosity, low calorific value, inherent instability | Clogs equipment, reduces efficiency, unreliable storage |

| Chemical Composition | High oxygen/nitrogen content, NOx emissions, catalyst deactivation | Corrosive, polluting, incompatible with refineries |

| Economic Viability | High cost and complexity of upgrading processes | Negates economic and environmental benefits |

Struggling with bio-oil analysis or processing? KINTEK specializes in lab equipment and consumables for advanced biofuel research. Our solutions help you accurately characterize viscosity, analyze chemical composition, and develop efficient upgrading processes. Contact our experts today to enhance your renewable energy projects with reliable laboratory technology.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is the purpose of a mixer? Achieve Perfect Baking Results with Less Effort

- What are the limitations of rotary vane pumps? Understanding Oil Dependence and Gas Compatibility

- How often should you change the oil in a rotary vane vacuum pump? Optimize Your Pump's Performance & Lifespan

- What is the advantage of rotary pump over centrifugal pump? Precision Handling for High-Viscosity Fluids

- What are the disadvantages of rotary vane vacuum pumps? Understand the Oil-Related Trade-offs

- Why Use Controlled Drying for Zr-doped CaO? Preserve Porosity and Prevent Agglomeration

- How do you evaporate a high boiling point solvent? Master Low-Pressure Techniques to Protect Your Samples

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing