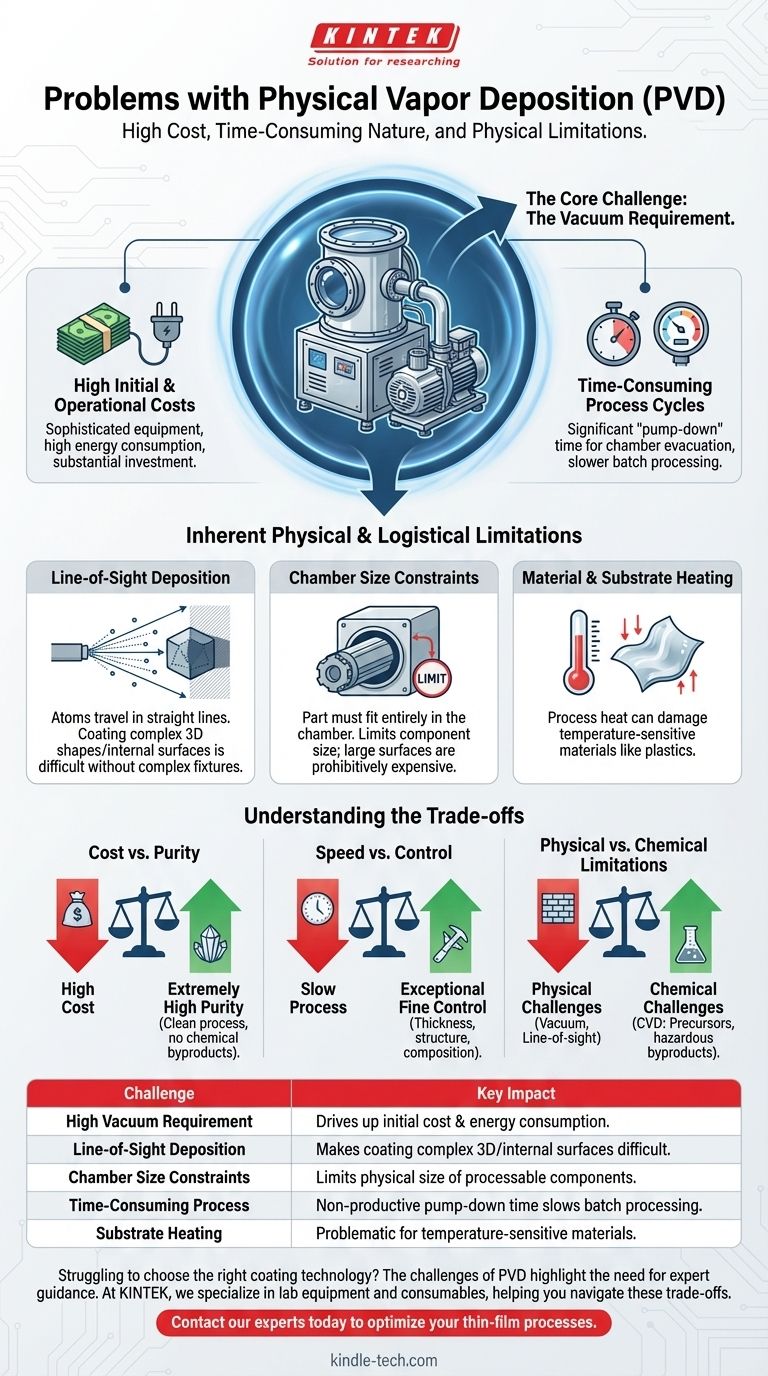

The primary problems with Physical Vapor Deposition (PVD) are its high cost and time-consuming nature, both of which stem directly from its fundamental requirement for a high-vacuum environment. These factors, combined with physical limitations like "line-of-sight" deposition, create significant barriers for certain applications.

While PVD is renowned for producing exceptionally pure and high-quality thin films, its core challenges are economic and logistical. The process is inherently expensive, relatively slow, and physically constrained by the size of the vacuum chamber and the straight-line path atoms travel from the source to the substrate.

The Core Challenge: The Vacuum Requirement

The need to operate in a vacuum is the source of PVD's most significant drawbacks. Creating and maintaining this environment is a complex and resource-intensive task.

High Initial and Operational Costs

PVD systems require sophisticated and expensive equipment, including high-power vacuum pumps, sealed chambers, and precise monitoring tools. This makes the initial capital investment substantial.

Furthermore, the process is energy-intensive, contributing to high ongoing operational costs.

Time-Consuming Process Cycles

A significant portion of any PVD process cycle is dedicated to "pump-down"—the time it takes to evacuate the chamber to the required vacuum level.

This non-productive time makes PVD inherently slower for batch processing compared to methods that operate at or near atmospheric pressure.

Inherent Physical and Logistical Limitations

Beyond the vacuum, the physical nature of how PVD works imposes practical constraints on its use.

"Line-of-Sight" Deposition

In PVD processes like sputtering and evaporation, atoms travel in a straight line from the source material to the target surface.

This means any area not in the direct line of sight of the source will receive little to no coating. Coating complex 3D shapes or the internal surfaces of a component is extremely difficult and often requires complex, rotating fixtures to achieve uniformity.

Chamber Size Constraints

The part being coated must fit entirely within the vacuum chamber. This creates a hard limit on the size of components that can be processed.

Coating very large surfaces can be prohibitively expensive or physically impossible, as it requires an equally large and costly vacuum chamber.

Material and Substrate Heating

Many PVD processes generate significant heat or require the substrate to be heated to achieve the desired film properties.

This can be problematic when working with temperature-sensitive materials, such as certain plastics or polymers, which may warp or degrade under these conditions.

Understanding the Trade-offs

Choosing a coating technology requires weighing its disadvantages against its unique strengths. The problems with PVD are the necessary trade-offs for its benefits.

Cost vs. Purity

PVD is expensive, but the vacuum environment ensures an extremely clean process. This results in coatings with very high purity, free from the chemical byproducts that can be present in methods like Chemical Vapor Deposition (CVD).

Speed vs. Control

While the overall process is time-consuming, PVD offers exceptionally fine control over the film's thickness, structure, and composition. For applications in optics and semiconductors, this level of precision is non-negotiable.

Physical vs. Chemical Limitations

PVD's challenges are primarily physical (line-of-sight, vacuum). In contrast, CVD often faces chemical challenges, such as finding stable, non-toxic precursor chemicals and dealing with potentially hazardous byproducts.

Making the Right Choice for Your Application

Your final decision must be guided by the primary goal of your project.

- If your primary focus is coating complex 3D geometries uniformly: You must carefully engineer a solution for PVD's line-of-sight limitation or investigate alternative methods.

- If your primary focus is cost-effectiveness for large-scale production: The high cost and slower cycle times of PVD may be a significant barrier.

- If your primary focus is achieving the highest film purity and precise thickness control: The challenges of PVD are often a necessary and worthwhile trade-off for achieving superior results.

Understanding these inherent limitations is the first step toward effectively leveraging PVD's powerful capabilities for your specific goals.

Summary Table:

| Challenge | Key Impact |

|---|---|

| High Vacuum Requirement | Drives up initial equipment cost and ongoing energy consumption. |

| Line-of-Sight Deposition | Makes coating complex 3D shapes and internal surfaces difficult. |

| Chamber Size Constraints | Limits the physical size of components that can be processed. |

| Time-Consuming Process | Non-productive pump-down time slows batch processing. |

| Substrate Heating | Can be problematic for temperature-sensitive materials like plastics. |

Struggling to choose the right coating technology for your lab's unique needs? The challenges of PVD—like high cost and line-of-sight limitations—highlight the importance of expert guidance. At KINTEK, we specialize in lab equipment and consumables, helping you navigate these trade-offs to select the perfect solution for your application, whether it's for superior purity or complex geometries. Contact our experts today to optimize your thin-film processes and achieve your project goals with confidence.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the process capabilities of ICPCVD systems? Achieve Low-Damage Film Deposition at Ultra-Low Temperatures

- Why is a Matching Network Indispensable in RF-PECVD for Siloxane Films? Ensure Stable Plasma and Uniform Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application