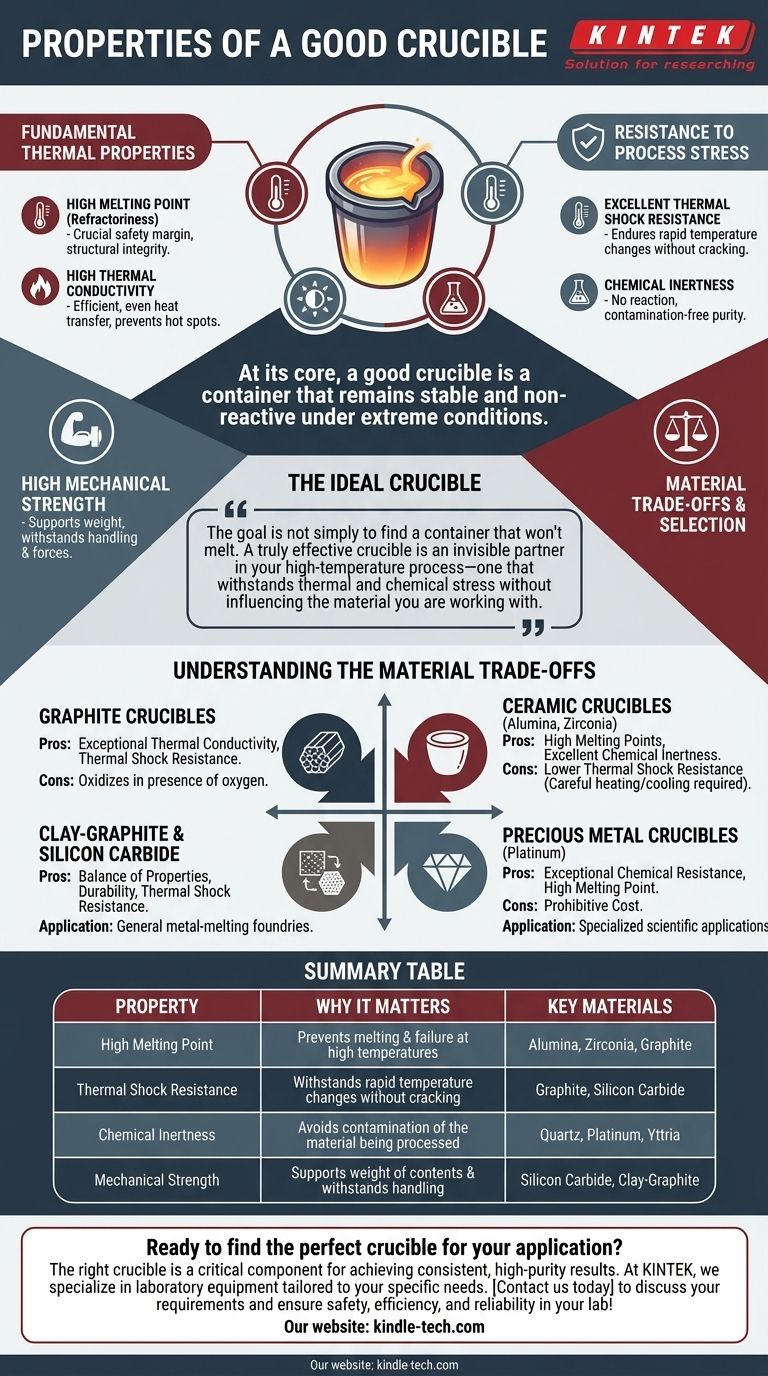

At its core, a good crucible is a container that remains stable and non-reactive under extreme conditions. The ideal crucible possesses four primary properties: a very high melting point (refractoriness), the ability to withstand rapid temperature changes without cracking (thermal shock resistance), chemical inertness to avoid contaminating its contents, and sufficient mechanical strength to hold molten material safely.

The goal is not simply to find a container that won't melt. A truly effective crucible is an invisible partner in your high-temperature process—one that withstands thermal and chemical stress without influencing the material you are working with.

Fundamental Thermal Properties

The most basic function of a crucible is to contain material at extreme temperatures. Its thermal properties are therefore the first and most critical consideration.

High Melting Point (Refractoriness)

A crucible's melting point must be significantly higher than the working temperature of your process. This property, known as refractoriness, is the absolute minimum requirement for any crucible.

This provides a crucial safety margin, ensuring the crucible maintains its structural integrity without softening or failing.

High Thermal Conductivity

Good thermal conductivity allows heat to transfer efficiently and evenly from the furnace to the material inside.

This prevents "hot spots" on the crucible's surface, reducing internal stresses. It also ensures the charge melts uniformly, leading to a more consistent and predictable process.

Low Coefficient of Thermal Expansion

This property measures how much a material expands when heated and contracts when cooled. A low coefficient of thermal expansion is highly desirable.

Materials that expand and contract less under temperature changes are far more resistant to cracking, a phenomenon known as thermal shock.

Resistance to Process Stress

Beyond simply enduring heat, a crucible must survive the dynamic stresses of the heating and cooling cycle while protecting the purity of its contents.

Excellent Thermal Shock Resistance

Thermal shock is the stress induced in a material by a rapid change in temperature. It is a primary cause of crucible failure.

Imagine pouring boiling water into a cold, thick glass—it can crack. A crucible with excellent thermal shock resistance, a result of high thermal conductivity and low thermal expansion, can endure these rapid changes without fracturing.

Chemical Inertness

A crucible must not react with, dissolve into, or otherwise contaminate the material it holds. This property is known as chemical inertness.

This is critical for applications in metallurgy and chemistry, where even trace amounts of contamination from the crucible can ruin the final product or invalidate experimental results.

High Mechanical Strength

The crucible must be strong enough to support the weight of its contents, especially when at peak temperature where some materials can lose strength.

It also needs to withstand the physical stress of being handled with tongs, loaded with raw materials, and enduring the forces of a bubbling or churning melt.

Understanding the Material Trade-offs

No single crucible material is perfect for every application. The choice always involves balancing properties, costs, and the specific demands of your process.

Graphite Crucibles

Graphite offers exceptional thermal conductivity and near-unmatched thermal shock resistance. However, it will oxidize (burn away) in the presence of oxygen at high temperatures, requiring a protective atmosphere or a limited lifespan.

Ceramic Crucibles (Alumina, Zirconia)

Ceramics like alumina and zirconia offer extremely high melting points and excellent chemical inertness, making them ideal for high-purity applications. Their primary drawback is lower thermal shock resistance, meaning they must be heated and cooled slowly and carefully to prevent cracking.

Clay-Graphite and Silicon Carbide

These are composite materials designed to offer a balance of properties. They combine the thermal shock resistance of graphite with the durability and strength of a ceramic or carbide matrix. They are often the workhorses of general metal-melting foundries.

Precious Metal Crucibles (Platinum)

For the most demanding laboratory analyses where ultimate purity is required, platinum crucibles are used. They offer exceptional chemical resistance and a high melting point, but their prohibitive cost limits them to specialized scientific applications.

Selecting the Right Crucible for Your Application

Your final choice depends entirely on the material you are working with and your primary goal.

- If your primary focus is melting common non-ferrous metals like aluminum, brass, or silver: A clay-graphite or silicon carbide crucible provides the best balance of cost, durability, and thermal performance.

- If your primary focus is high-purity laboratory work or melting glass: An alumina, quartz, or zirconia crucible is necessary to prevent contamination, but requires careful heating and cooling protocols.

- If your primary focus is working with highly reactive or corrosive materials: You must select a crucible specifically known for its inertness to that substance, such as yttria or a specially glazed ceramic.

By understanding these core properties, you can choose a crucible that is not just a container, but a reliable and effective tool for your work.

Summary Table:

| Property | Why It Matters | Key Materials |

|---|---|---|

| High Melting Point (Refractoriness) | Prevents melting and failure at high temperatures | Alumina, Zirconia, Graphite |

| Thermal Shock Resistance | Withstands rapid temperature changes without cracking | Graphite, Silicon Carbide |

| Chemical Inertness | Avoids contamination of the material being processed | Quartz, Platinum, Yttria |

| Mechanical Strength | Supports weight of contents and withstands handling | Silicon Carbide, Clay-Graphite |

Ready to find the perfect crucible for your application? The right crucible is more than just a container—it's a critical component for achieving consistent, high-purity results in your high-temperature processes. At KINTEK, we specialize in providing laboratory equipment and consumables tailored to your specific needs, whether you're working with common non-ferrous metals, conducting high-purity research, or handling reactive materials.

Contact us today to discuss your requirements and let our experts help you select a crucible that ensures safety, efficiency, and reliability in your lab!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

People Also Ask

- Why use ceramic combustion boats for T91 steel corrosion testing? Ensure Data Accuracy and Chemical Inertness

- Why do crucibles not melt? The Science of Refractory Materials for High-Temperature Use

- Why are corrosion-resistant alloy crucibles required? Ensure Purity in Molten Salt Electrodeposition

- Why are corundum crucibles preferred for magnesium evaporation? Ensure Purity in High-Temperature Reduction

- Can a crucible crack? Prevent Thermal Shock and Extend Crucible Life

- What materials can be used as a crucible? Select the Right Material for Your High-Temperature Application

- What functions do steel crucibles and protective atmospheres serve? Ensure Purity in Mg-Ag Alloy Melting

- Why is a high-purity alumina crucible required for LLTO calcination? Ensure Material Purity and Stoichiometry