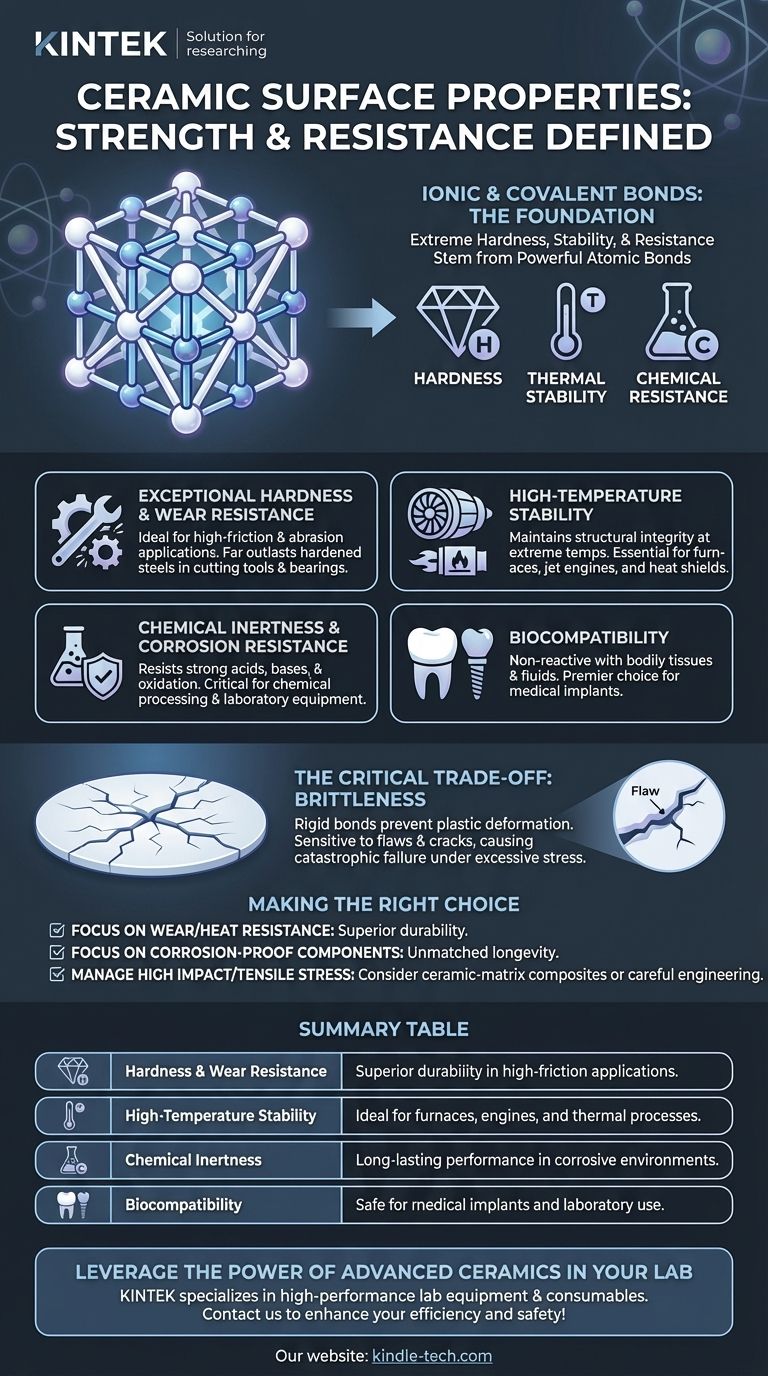

In essence, ceramic surfaces are defined by their extreme hardness, stability, and resistance. These characteristics stem from the powerful atomic bonds—ionic and covalent—that hold the material together, making them exceptionally durable in harsh mechanical, thermal, and chemical environments.

The core principle to understand is that the very same rigid atomic structure that gives ceramics their exceptional strength and resistance is also the source of their primary weakness: brittleness.

The Foundation: Why Atomic Bonds Define Everything

The properties of a material are a direct reflection of how its atoms are joined together. For advanced ceramics, this foundation is built on incredibly strong and stable bonds.

Understanding Ionic and Covalent Bonds

Unlike metals where electrons flow freely, the atoms in ceramics are locked into a rigid lattice by either ionic bonds (where electrons are transferred) or covalent bonds (where electrons are shared).

Think of these bonds as a form of atomic "super glue." This rigid, tightly-packed structure is incredibly difficult to disrupt.

The Impact on Hardness and Strength

Because these bonds are so strong, it takes a tremendous amount of force to displace the atoms. This directly translates into high compressive strength and exceptional hardness, making ceramic surfaces highly resistant to scratching and surface deformation.

The Source of Thermal and Chemical Resistance

Breaking these powerful bonds also requires a massive amount of energy. This is why ceramics exhibit very high temperature resistance and are chemically inert; they simply don't have the weak points that allow heat or corrosive agents to easily break the material down.

Key Properties of Ceramic Surfaces Explained

This unique atomic structure gives rise to a set of highly desirable engineering properties.

Exceptional Hardness & Wear Resistance

Ceramic surfaces are among the hardest materials known. This makes them ideal for applications involving friction and abrasion, such as cutting tools, industrial bearings, and protective coatings, where they can far outlast hardened steels.

High-Temperature Stability

Most ceramics can maintain their structural integrity and strength at temperatures that would cause metals to soften and fail. This makes them essential for components inside furnaces, jet engines, and heat shields.

Chemical Inertness & Corrosion Resistance

Ceramics are highly resistant to almost all forms of chemical attack, including strong acids, bases, and oxidation (rust). This property is critical for equipment used in chemical processing, laboratory settings, and even within the human body.

Biocompatibility

Because they are so stable and chemically inert, many ceramics are biocompatible. They do not react with bodily tissues or fluids, making them a premier choice for medical implants like dental crowns and hip joint replacements.

Understanding the Critical Trade-off: Brittleness

The defining strength of ceramics is inextricably linked to their most significant limitation.

The Inflexibility of Strong Bonds

The same rigid bonds that provide strength also prevent the material from deforming under stress. Unlike a metal that will bend or dent, a ceramic material has no mechanism for plastic deformation.

Sensitivity to Flaws and Cracks

When a ceramic is subjected to excessive tensile stress, its energy has nowhere to go. Any microscopic surface flaw or internal defect can become a concentration point for this stress, causing a crack to propagate almost instantly and lead to catastrophic failure. This is why a ceramic plate shatters when dropped.

Making the Right Choice for Your Application

Selecting a ceramic requires balancing its unparalleled durability against its inherent brittleness.

- If your primary focus is extreme wear or heat resistance: The hardness and thermal stability of ceramics make them the ideal choice, far superior to metals or polymers.

- If your primary focus is corrosion-proof components: The chemical inertness of ceramics provides unmatched longevity in environments that would rapidly degrade other materials.

- If your application involves high impact or tensile stress: You must manage the inherent brittleness through careful engineering design or by considering ceramic-matrix composites that incorporate reinforcing fibers.

Understanding this fundamental trade-off is the key to successfully leveraging the power of advanced ceramics in your work.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Hardness & Wear Resistance | Extreme resistance to scratching and abrasion. | Superior durability in high-friction applications. |

| High-Temperature Stability | Maintains integrity at extreme temperatures. | Ideal for furnaces, engines, and thermal processes. |

| Chemical Inertness | Resists acids, bases, and oxidation. | Long-lasting performance in corrosive environments. |

| Biocompatibility | Non-reactive with biological tissues. | Safe for medical implants and laboratory use. |

Leverage the power of advanced ceramics in your lab. KINTEK specializes in high-performance lab equipment and consumables designed to withstand harsh conditions. Whether you need durable furnace components, corrosion-resistant tools, or biocompatible materials, our solutions are engineered for reliability and precision. Contact us today to discuss how our ceramics can enhance your laboratory's efficiency and safety!

Visual Guide

Related Products

- Advanced Engineering Fine Ceramics Aluminum Nitride (AlN) Ceramic Sheet

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Aluminum Oxide Al2O3 Heat Sink for Insulation

- High Temperature Aluminum Oxide (Al2O3) Protective Tube for Engineering Advanced Fine Ceramics

- Boron Nitride (BN) Ceramic Tube

People Also Ask

- What is the alternative to CNT? Master React Form State Management with the Right Approach

- What are alloys in simple words? Unlock the Power of Engineered Materials

- Which of the following is used in furnace to withstand high temperature? Key Materials for Extreme Heat

- What is the maximum temperature for ceramics? Find the Right Material for Your High-Temp Application

- Does nanomaterials have potential hazards to human health? Understanding the Risks and Safe Handling