In essence, sputtering is a physical vapor deposition (PVD) process that involves four primary stages: creating a vacuum and introducing a process gas, generating a plasma to create energetic ions, using those ions to bombard a target material and eject atoms, and finally, allowing those ejected atoms to deposit onto a substrate, forming a thin film.

Sputtering is best understood as a highly controlled, atomic-scale sandblasting process. Inside a vacuum, energized gas ions are accelerated into a source material, physically knocking atoms loose, which then travel and coat a nearby substrate one atom at a time.

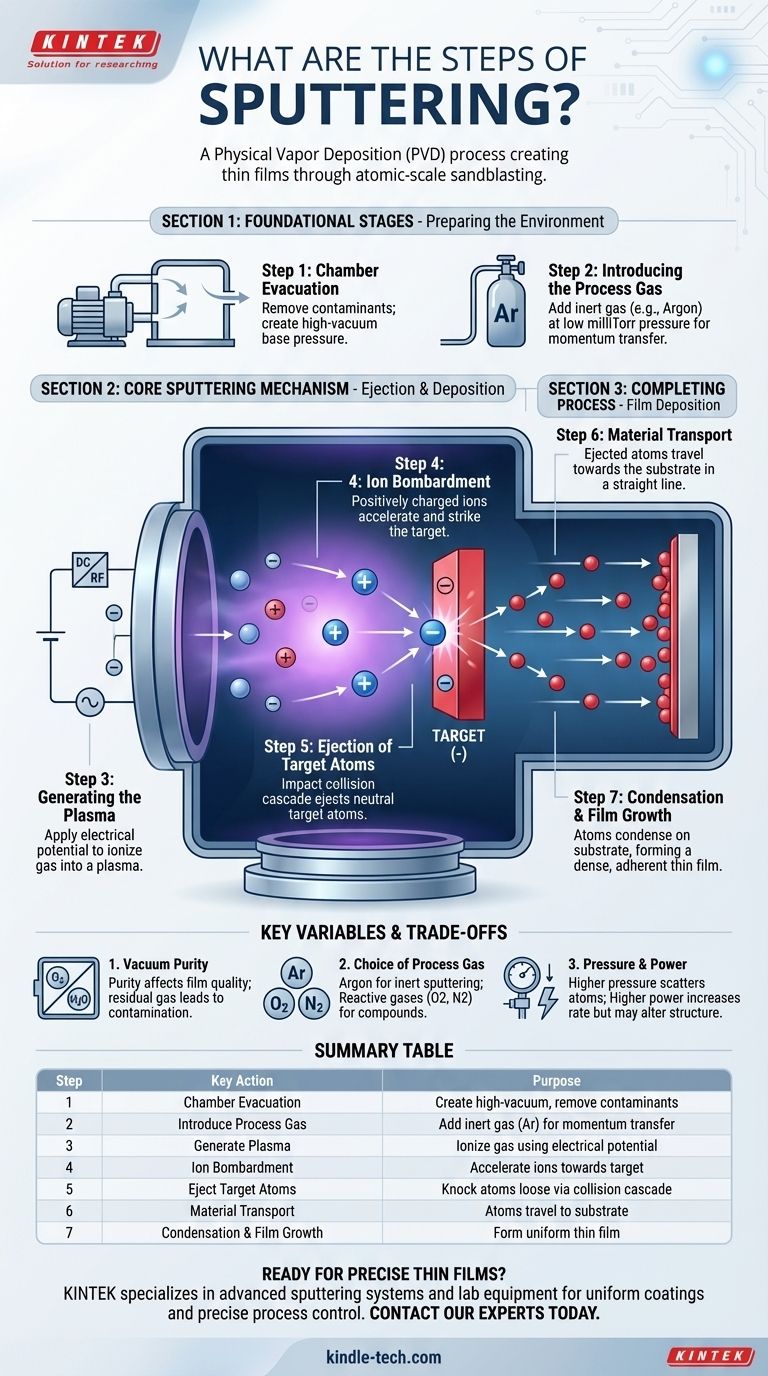

The Foundational Stages: Preparing the Environment

Before any material can be deposited, the system must be prepared to ensure the purity and quality of the final film. This setup is a critical, non-negotiable part of the process.

Step 1: Chamber Evacuation

The first step is to place the substrate (the object to be coated) and the target (the source material) inside a sealed chamber. This chamber is then evacuated by vacuum pumps.

The goal is to remove nearly all air and other contaminants like water vapor. This creates a high-vacuum environment, often referred to as the base pressure, which prevents unwanted molecules from being incorporated into the film and compromising its properties.

Step 2: Introducing the Process Gas

Once a sufficient vacuum is achieved, a high-purity process gas is introduced into the chamber.

This is most commonly an inert gas like Argon (Ar) because it is heavy enough for effective momentum transfer and does not chemically react with the target material. The pressure of this gas is carefully regulated, typically in the low-pressure milliTorr range.

The Core Sputtering Mechanism

With the environment prepared, the active process of ejecting and depositing material can begin. This is driven by the creation of a plasma.

Step 3: Generating the Plasma

A strong electrical potential (either DC or Radio Frequency) is applied within the chamber, energizing the process gas.

This high energy strips electrons from the gas atoms, creating a mixture of positively charged ions and free electrons. This ionized gas is known as a plasma.

Step 4: Ion Bombardment

The target material is given a negative electrical charge. Because opposites attract, the positively charged ions from the plasma are forcefully accelerated toward the negatively charged target.

These ions strike the surface of the target with significant kinetic energy.

Step 5: Ejection of Target Atoms

The impact of an ion on the target initiates a collision cascade, transferring momentum to the atoms within the target material.

If the energy transferred to a surface atom is greater than its binding energy, that atom is physically knocked loose, or "sputtered," from the target. These ejected particles are neutral atoms, not ions.

Completing the Process: Film Deposition

The final stages involve the transport of the sputtered material and the growth of the new film.

Step 6: Material Transport

The sputtered atoms travel in a straight line from the target through the low-pressure gas environment.

The vacuum is crucial here, as it minimizes the chance that the sputtered atoms will collide with other gas molecules before reaching their destination.

Step 7: Condensation and Film Growth

When the sputtered atoms reach the substrate, they condense on its surface.

Over time, millions of these arriving atoms build upon one another, forming a dense, uniform, and highly adherent thin film.

Understanding Key Variables and Trade-offs

The quality and characteristics of the sputtered film are not accidental; they are a direct result of controlling key process variables.

The Critical Role of Vacuum Purity

Any residual gas (like oxygen or water) in the chamber can react with the sputtered atoms or embed in the growing film as a contaminant. A poor vacuum leads directly to a contaminated, low-quality film.

The Choice of Process Gas

While Argon is common for its inertness, reactive gases like Oxygen (O2) or Nitrogen (N2) can be intentionally added. This allows for reactive sputtering, where the sputtered metal atoms react with the gas to form compounds like oxides or nitrides on the substrate.

The Impact of Pressure and Power

The gas pressure and the applied electrical power directly influence the outcome. Higher pressure can increase the number of collisions, potentially scattering the sputtered atoms and reducing uniformity. Higher power increases the ion energy, which in turn increases the deposition rate but can also affect the film's structure.

The Sputtering Process at a Glance

To apply this knowledge, think of the process in three distinct phases, each with a clear objective.

- If your focus is the Setup: The primary goal is creating an ultra-pure, low-pressure environment to prevent contamination and allow for unimpeded particle travel.

- If your focus is the Mechanism: The goal is to use an electric field to create and accelerate gas ions, turning them into precision tools for atomic-scale bombardment of a target.

- If your focus is the Result: The goal is the line-of-sight transport and condensation of ejected atoms onto a substrate, meticulously building a thin film from the ground up.

Ultimately, sputtering is a powerful and precise method for engineering materials with specific properties by controlling a physical chain reaction at the atomic level.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Chamber Evacuation | Remove contaminants by creating a high-vacuum base pressure |

| 2 | Introduce Process Gas | Add inert gas (e.g., Argon) for momentum transfer |

| 3 | Generate Plasma | Ionize gas using electrical potential (DC/RF) |

| 4 | Ion Bombardment | Accelerate ions toward the negatively charged target |

| 5 | Eject Target Atoms | Knock atoms loose via collision cascade |

| 6 | Material Transport | Sputtered atoms travel in a straight line to the substrate |

| 7 | Condensation & Film Growth | Atoms build up to form a uniform, adherent thin film |

Ready to achieve precise, high-quality thin films in your lab? KINTEK specializes in advanced sputtering systems and lab equipment designed for researchers and engineers. Our solutions deliver uniform coatings, precise process control, and reliable performance for your most demanding applications. Contact our experts today to discuss how we can optimize your deposition process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Evaporation Boat for Organic Matter

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- Why is high-speed wafer rotation necessary for vertical CVD? Master Flow Engineering for 4H-SiC Thin Films

- What is the difference between thin film coating and thick film coating? A Guide to Deposition Processes

- What is the process of ion beam deposition? Achieve Unmatched Precision in Thin-Film Coating

- How are carbon nanotubes synthesized? A Guide to Arc Discharge, Laser Ablation, and CVD Methods

- Which gases are used in CVD diamond process? Unlock the Secrets of Lab-Grown Diamond Creation

- What is the vapor deposition of metals? Build Superior, High-Purity Metal Coatings

- What is physical vapor deposition for jewelry? A Durable, High-Tech Finish for Modern Wear

- What is the principle of MOCVD? A Guide to High-Purity Thin Film Deposition