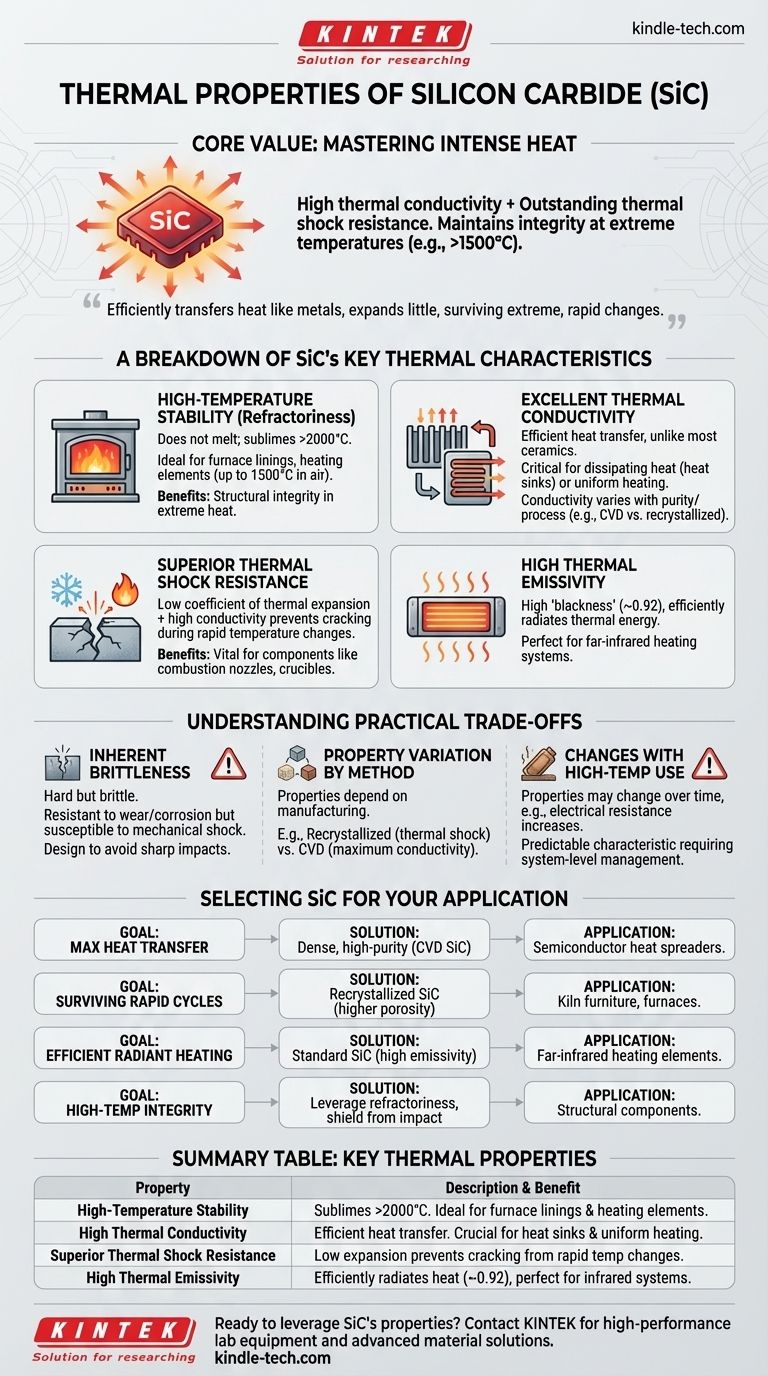

In short, silicon carbide is defined by its exceptional ability to manage intense heat. It combines high thermal conductivity with outstanding resistance to thermal shock and can maintain its integrity at extremely high temperatures. This unique combination makes it a critical material for applications ranging from industrial furnaces to advanced semiconductors.

The core value of silicon carbide lies in a rare pairing of properties: it transfers heat as efficiently as many metals while expanding and contracting very little. This allows it to survive extreme, rapid temperature changes that would cause most other materials to fail.

A Breakdown of SiC's Key Thermal Characteristics

To understand why silicon carbide (SiC) is chosen for such demanding roles, we must look at its individual thermal properties. Each one solves a specific engineering challenge related to heat.

High-Temperature Stability (Refractoriness)

Silicon carbide does not melt at atmospheric pressure; it sublimes at very high temperatures. Its refractoriness, or ability to withstand heat without deforming, is exceptional, often cited as being over 2000°C.

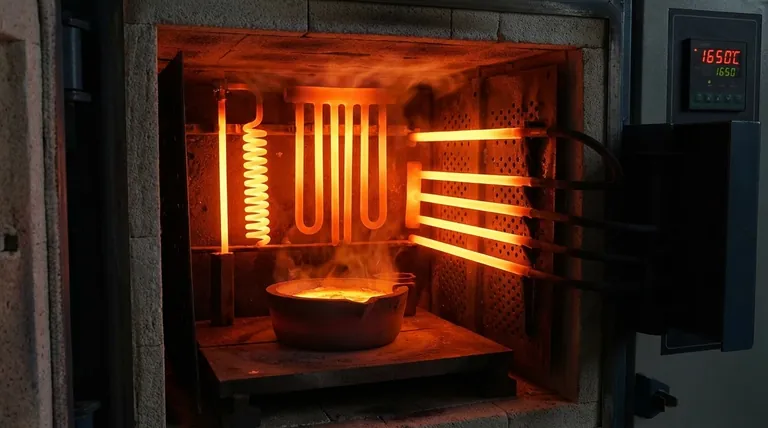

For practical applications, such as SiC heating elements, it can operate in air at temperatures up to 1500°C, far exceeding the limits of most metals. This makes it ideal for furnace linings, kiln furniture, and guide rails in high-temperature environments.

Excellent Thermal Conductivity

Unlike most ceramics, which are thermal insulators, silicon carbide has a high thermal conductivity. This means it transfers heat very efficiently.

This property is critical for two opposing goals: either to dissipate heat quickly (like in semiconductor heat sinks) or to transfer heat uniformly (as in heat exchangers and furnace muffles). The purity and density of the SiC, often determined by the manufacturing process (e.g., CVD vs. recrystallized), can significantly influence this conductivity.

Superior Thermal Shock Resistance

Thermal shock is the stress a material endures when its temperature changes rapidly, causing it to crack. SiC has a very low coefficient of thermal expansion, meaning it expands and contracts very little when heated or cooled.

Combined with its high thermal conductivity, this low expansion gives SiC excellent resistance to thermal shock. It can withstand rapid heating and cooling cycles without fracturing, a vital trait for components like combustion nozzles and crucibles.

High Thermal Emissivity

Silicon carbide has a high emissivity, or "blackness," of around 0.92. This means it is extremely efficient at radiating thermal energy.

This property is intentionally leveraged in applications like far-infrared heating plates. The material effectively converts electrical energy into radiant heat, making it an excellent choice for efficient, non-contact heating systems.

Understanding the Practical Trade-offs

While its thermal properties are elite, silicon carbide is not a universally perfect material. Acknowledging its trade-offs is key to successful implementation.

Inherent Brittleness

Silicon carbide is a very hard but also brittle material. While it is exceptionally resistant to wear, corrosion, and thermal stress, it is susceptible to failure from mechanical shock or impact.

Designs using SiC must account for this brittleness, ensuring components are not subjected to sharp impacts or tensile loads they cannot handle.

Property Variation by Manufacturing Method

"Silicon carbide" refers to a family of materials, not a single substance. Its properties depend heavily on the manufacturing process.

For example, recrystallized SiC often has higher porosity, which enhances its thermal shock resistance, making it ideal for kiln furniture. In contrast, CVD (Chemical Vapor Deposition) SiC is theoretically dense and intrinsically pure, offering maximum thermal conductivity for semiconductor applications.

Changes with High-Temperature Use

In some applications, SiC's properties can gradually change over its service life. For instance, SiC resistors used at very high temperatures will slowly increase their electrical resistance.

This is not a failure but a predictable characteristic that must be managed at the system level. For heating circuits, this may require an auto-transformer with multiple taps to adjust the voltage and maintain consistent power output over time.

Selecting SiC for Your Application

Your choice of silicon carbide should be directly guided by your primary engineering goal.

- If your primary focus is maximum heat transfer: Seek out dense, high-purity forms like CVD SiC for applications such as semiconductor heat spreaders.

- If your primary focus is surviving rapid temperature cycles: A recrystallized SiC is often ideal for its superior thermal shock resistance in kilns and furnaces.

- If your primary focus is efficient radiant heating: Utilize standard SiC for its high emissivity, making it perfect for far-infrared heating elements.

- If your primary focus is high-temperature structural integrity: Leverage SiC's refractoriness but be mindful of its brittleness, designing to shield it from mechanical impact.

By understanding these distinct thermal characteristics and their trade-offs, you can effectively leverage silicon carbide's power in the most demanding thermal management applications.

Summary Table:

| Key Thermal Property | Description & Benefit |

|---|---|

| High-Temperature Stability | Does not melt; sublimes above 2000°C. Ideal for furnace linings and heating elements. |

| High Thermal Conductivity | Transfers heat efficiently like a metal. Crucial for heat sinks and uniform heating. |

| Superior Thermal Shock Resistance | Low expansion and high conductivity prevent cracking from rapid temperature changes. |

| High Thermal Emissivity | Efficiently radiates heat (emissivity ~0.92), perfect for infrared heating systems. |

Ready to leverage silicon carbide's exceptional thermal properties in your lab or production process? KINTEK specializes in high-performance lab equipment and consumables, including solutions built with advanced materials like SiC. Whether you need components for a high-temperature furnace, a custom heating element, or expert advice on material selection for thermal management, our team is here to help. Contact us today to discuss how we can provide the right SiC-based solution for your demanding application.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

People Also Ask

- What are the drawbacks of tungsten carbide? Understanding the Brittleness vs. Hardness Trade-off

- Why is sintering necessary for ceramic processing? Transform Powder into High-Performance Components

- What is the effect of sintering temperature on density and hardness? Optimize Your Material's Properties

- What is the thermal resistance of SiC? Understanding Its High Thermal Conductivity for Superior Performance

- Where are ceramics used in the body? Key Applications in Orthopedics, Dentistry & Bone Repair

- Can ceramics withstand high temperatures? Discover Their Exceptional Heat Resistance

- What is the material used in high temperature furnace? Selecting the Right Ceramic for Extreme Heat

- Why is Silicon Carbide high-conductivity ceramic used in reactors? Create a Protective Slag Layer for Biomass Systems