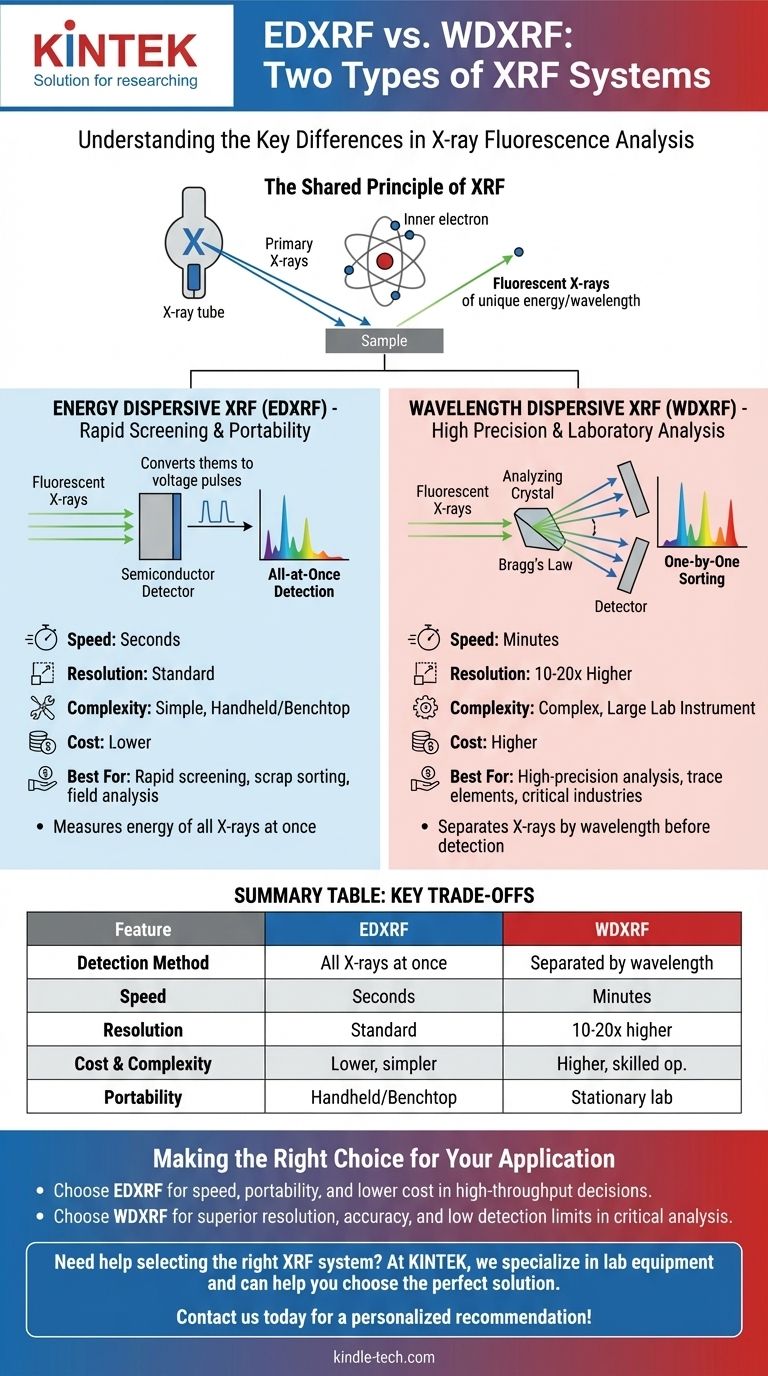

In X-ray Fluorescence (XRF) analysis, the two fundamental types of systems are Energy Dispersive XRF (EDXRF) and Wavelength Dispersive XRF (WDXRF). The core difference between them is not the X-rays themselves, but the method used to separate and measure the characteristic fluorescent X-rays emitted from the sample. EDXRF detectors measure the energy of all X-rays at once, while WDXRF systems physically separate the X-rays by their specific wavelengths before measuring them.

The choice between these two technologies presents a classic trade-off. EDXRF provides speed, simplicity, and portability for rapid screening applications. WDXRF delivers superior resolution, precision, and sensitivity for demanding laboratory analysis where accuracy is paramount.

How XRF Works: The Shared Principle

Before comparing the two system types, it's crucial to understand the process they both share. All XRF analysis is a two-step process.

The Excitation Process

First, a primary X-ray beam from a source (typically an X-ray tube) is directed at the material being analyzed. This high-energy beam strikes the atoms within the sample.

The Fluorescence Event

The energy from the primary beam is absorbed by an atom, causing an electron from an inner orbital shell to be ejected. This creates an unstable vacancy, which is immediately filled by an electron from a higher-energy outer shell.

As this electron drops to the lower energy level, the atom releases the excess energy by emitting a secondary X-ray. This emitted X-ray is called a "fluorescent" X-ray, and its energy (and corresponding wavelength) is unique to the element it came from.

The Point of Divergence

Both EDXRF and WDXRF rely on this same fluorescence principle. The divergence occurs in how they collect, sort, and count these secondary X-rays to generate a compositional analysis.

Understanding Energy Dispersive XRF (EDXRF)

EDXRF is the more common and accessible of the two technologies, forming the basis for nearly all portable and benchtop XRF analyzers.

The "All-at-Once" Detection Method

In an EDXRF system, the fluorescent X-rays emitted from the sample travel directly to a semiconductor detector. This detector is designed to absorb the energy of each incoming X-ray and convert it into a proportional voltage pulse.

The system processes thousands of these events per second, sorting the pulses by their voltage to build a spectrum. Think of it like a microphone that captures all the notes of a chord at once and a computer that then identifies the individual notes based on their frequencies.

Key Characteristics

EDXRF systems are known for their speed, as they simultaneously collect data for all elements from Sodium (Na) to Uranium (U). Their design is mechanically simple, resulting in lower costs, smaller footprints, and the possibility of handheld, battery-powered devices.

Understanding Wavelength Dispersive XRF (WDXRF)

WDXRF is a more complex, high-performance laboratory technique used when the highest levels of accuracy and resolution are required.

The "One-by-One" Sorting Method

Instead of detecting all X-rays at once, a WDXRF system physically separates the X-rays based on their wavelength before they reach the detector.

This is achieved using an analyzing crystal. Based on a principle called Bragg's Law, the crystal is set to a specific angle that will only diffract X-rays of a single, precise wavelength toward the detector. Think of it like a prism that can be tuned to only pass red light, then green light, then blue light, one at a time.

Key Characteristics

By scanning through different crystal angles, the system builds an extremely high-resolution spectrum, wavelength by wavelength. This physical separation prevents the common issue of spectral peak overlap that can affect EDXRF, especially in complex metal alloys.

Understanding the Trade-offs

Choosing between EDXRF and WDXRF is not about which is "better" overall, but which is the right tool for a specific analytical job.

Resolution and Precision vs. Speed

The primary trade-off is between resolution and speed. WDXRF offers 10-20 times better spectral resolution than EDXRF. This allows it to easily distinguish between elements with very close energy lines (e.g., Tantalum and Tungsten), which can be challenging for EDXRF.

However, this precision comes at the cost of speed. A WDXRF scan can take several minutes, whereas an EDXRF can provide a comprehensive analysis in seconds.

Sensitivity and Detection Limits

Because of its superior peak-to-background ratio, WDXRF generally offers lower detection limits. It is particularly superior for light elements (like Sodium, Magnesium, and Aluminum) where EDXRF systems often struggle.

Cost and Operational Complexity

There is a massive difference in cost and complexity. EDXRF systems are significantly less expensive, easier to operate, and require less maintenance. Handheld units bring the analysis directly to the field.

WDXRF systems are large, stationary laboratory instruments that cost several times more than their EDXRF counterparts. They require a controlled environment, more extensive user training, and regular maintenance by skilled technicians.

Making the Right Choice for Your Application

Your analytical goal should be the sole driver of your technology choice. There is very little overlap in their ideal use cases.

- If your primary focus is rapid screening, scrap metal sorting, or general product quality control: Choose EDXRF. Its unmatched speed, portability, and lower cost of ownership are ideal for high-throughput decision-making.

- If your primary focus is high-precision chemical analysis, materials research, or contract laboratory services: Choose WDXRF. Its superior resolution, accuracy, and low detection limits are necessary for certification, process control in critical industries (like cement or petroleum), and advanced research.

- If your primary focus is quantifying light elements or trace elements in a complex matrix: Choose WDXRF. It is the technically superior and more reliable choice for these demanding applications.

Ultimately, selecting the right XRF system depends on a clear understanding of your required analytical precision, speed, and operational environment.

Summary Table:

| Feature | EDXRF | WDXRF |

|---|---|---|

| Detection Method | Measures energy of all X-rays at once | Separates X-rays by wavelength before detection |

| Best For | Rapid screening, field analysis, scrap sorting | High-precision lab analysis, trace element detection |

| Speed | Seconds per analysis | Minutes per analysis |

| Resolution | Standard | 10-20x higher |

| Cost & Complexity | Lower cost, simpler operation | Higher cost, requires skilled operation |

| Portability | Handheld and benchtop options available | Large, stationary lab instrument |

Need help selecting the right XRF system for your laboratory?

At KINTEK, we specialize in lab equipment and consumables, serving all your laboratory needs. Whether you require the rapid screening capabilities of EDXRF or the high-precision analysis of WDXRF, our experts can help you choose the perfect solution for your material analysis requirements.

Contact us today to discuss your specific application and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Optical Window Glass Substrate Wafer CaF2 Substrate Window Lens

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- What function does a sieving system perform during HPS powder pretreatment? Ensure Uniform Particle Size Distribution