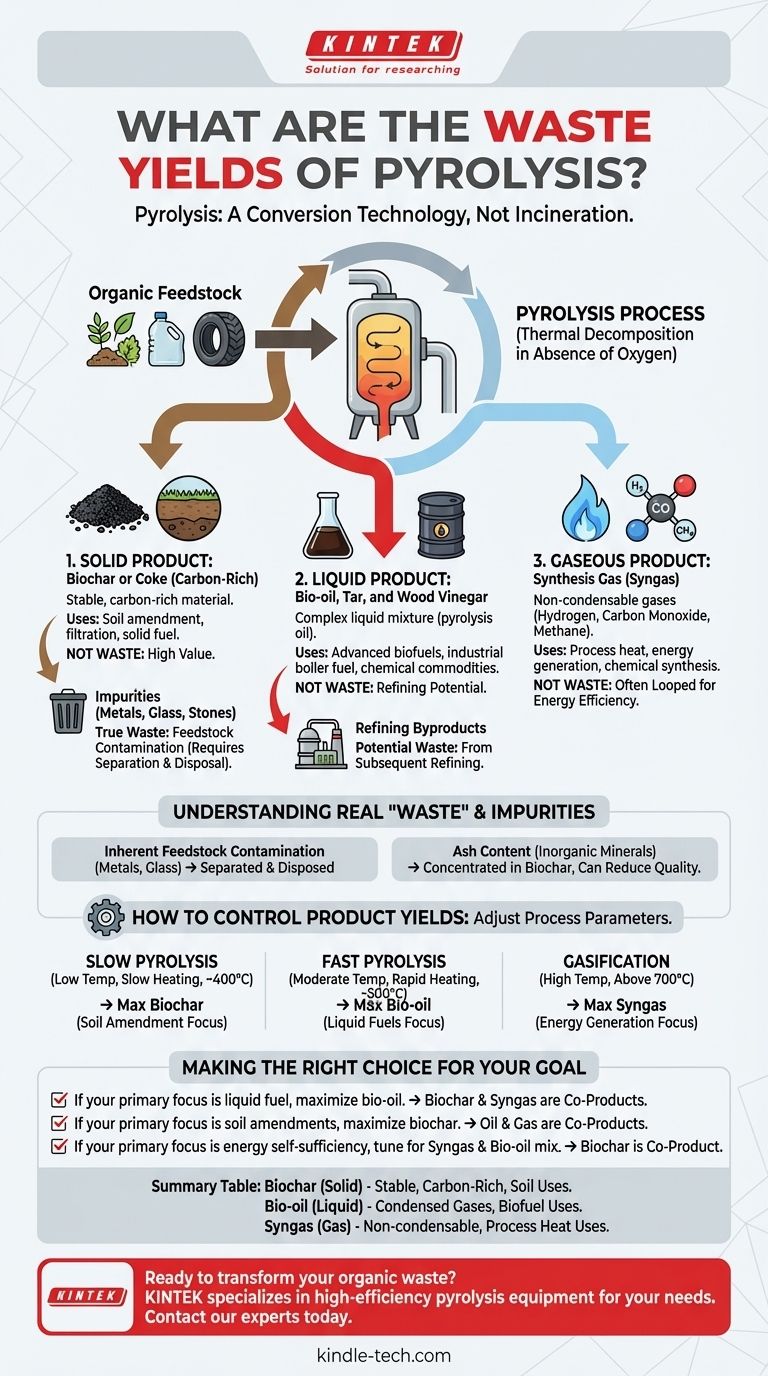

In principle, a well-run pyrolysis system generates very little true "waste." The process is designed to convert nearly 100% of a feedstock into three valuable product streams: a solid (biochar), a liquid (bio-oil), and a non-condensable gas (syngas). What is often mislabeled as "waste" is simply one of these co-products that may not be the primary target for a specific operation.

The core concept to understand is that pyrolysis is a conversion technology, not an incineration or disposal method. Its primary function is to transform organic material into valuable solids, liquids, and gases, with the proportions of each being highly controllable.

The Three Primary Product Streams

Pyrolysis thermally decomposes organic material in the absence of oxygen. This controlled process ensures the material doesn't combust, but rather breaks down into new, commercially viable substances.

Solid Product: Biochar or Coke

The solid residue left after pyrolysis is a stable, carbon-rich material known as biochar (from biomass) or coke (from other materials like plastics or tires).

This is not waste; it has significant value. It is often used in agriculture to improve soil health, as a sorbent for filtration and remediation, or as a solid fuel similar to charcoal.

Liquid Product: Bio-oil, Tar, and Wood Vinegar

As the process gases cool, a complex liquid mixture condenses. This is broadly referred to as pyrolysis oil or bio-oil.

This liquid can be refined into advanced biofuels for engines and turbines or used directly as an industrial boiler fuel. It also serves as a source for valuable chemical commodities, offering a sustainable alternative to petroleum-based products.

Gaseous Product: Synthesis Gas (Syngas)

The non-condensable gases that remain after the liquid has been extracted form a mixture called synthesis gas, or syngas.

This gas is rich in components like hydrogen (H₂), carbon monoxide (CO), and methane (CH₄). Critically, this syngas is often looped back to provide the heat required for the pyrolysis reaction, making the entire process highly energy-efficient and potentially self-sustaining.

Understanding the Real "Waste" and Impurities

While the core process is highly efficient, impurities in the feedstock or inefficiencies in the system can create outputs that are accurately described as waste.

Inherent Feedstock Contamination

The most significant source of true waste is non-organic contamination present in the initial feedstock. Materials like metals, glass, stones, and dirt cannot be converted by pyrolysis.

These materials will remain in the solid char product, from which they must be separated. This separated inorganic material is a true waste stream that requires disposal.

Ash Content

Organic feedstocks naturally contain a small percentage of inorganic minerals. During pyrolysis, these minerals are concentrated in the biochar as ash.

While a small amount of ash can be beneficial for agricultural applications, high ash content can reduce the quality and value of the biochar, limiting its use cases.

Incomplete Conversion or Refining Byproducts

An inefficiently run process may lead to incomplete conversion, leaving behind unreacted feedstock. Furthermore, if the bio-oil is refined into higher-grade fuels, that refining process can create its own secondary byproducts and waste streams that need to be managed.

How to Control Product Yields

You can control the output of a pyrolysis unit by adjusting the process parameters. The "yield" is not fixed; it is a function of your operational goal.

Slow Pyrolysis for Maximizing Biochar

Using lower temperatures (around 400°C) and a slow heating rate maximizes the production of the solid biochar. This is the preferred method when the primary goal is soil amendment or carbon sequestration.

Fast Pyrolysis for Maximizing Bio-oil

Using moderate temperatures (around 500°C) and extremely rapid heating rates favors the production of the liquid bio-oil. This is the focus for operators who want to produce liquid fuels or chemical feedstocks.

Gasification for Maximizing Syngas

At much higher temperatures (above 700°C), the process shifts toward gasification. This breaks down the material even further, maximizing the yield of syngas for energy generation or the synthesis of chemicals like hydrogen.

Making the Right Choice for Your Goal

The "waste" from pyrolysis is determined entirely by your objective. Define what you consider the primary product, and the other outputs become co-products to be utilized.

- If your primary focus is producing liquid fuel: Use fast pyrolysis and plan to either use the resulting biochar and syngas on-site or sell them as secondary products.

- If your primary focus is creating high-quality soil amendments: Use slow pyrolysis to maximize biochar yield and use the co-produced oil and gas to power your operation.

- If your primary focus is energy self-sufficiency: Tune the process to produce the optimal mix of syngas and bio-oil needed to power your facility and equipment.

Ultimately, pyrolysis transforms a potential waste problem into a set of valuable solutions.

Summary Table:

| Product Stream | Description | Common Uses |

|---|---|---|

| Biochar (Solid) | Stable, carbon-rich solid residue | Soil amendment, filtration, solid fuel |

| Bio-oil (Liquid) | Condensed liquid from process gases | Biofuel, industrial fuel, chemical feedstock |

| Syngas (Gas) | Non-condensable gas mixture (H₂, CO, CH₄) | Process heat, energy generation, chemical synthesis |

Ready to transform your organic waste streams into valuable products? KINTEK specializes in high-efficiency pyrolysis equipment and consumables tailored to your laboratory or pilot-scale needs. Whether your goal is to maximize biochar for research, produce bio-oil for fuel analysis, or optimize syngas for energy studies, our solutions ensure precise control and reliable performance. Contact our experts today to discuss how we can help you achieve your resource recovery goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success