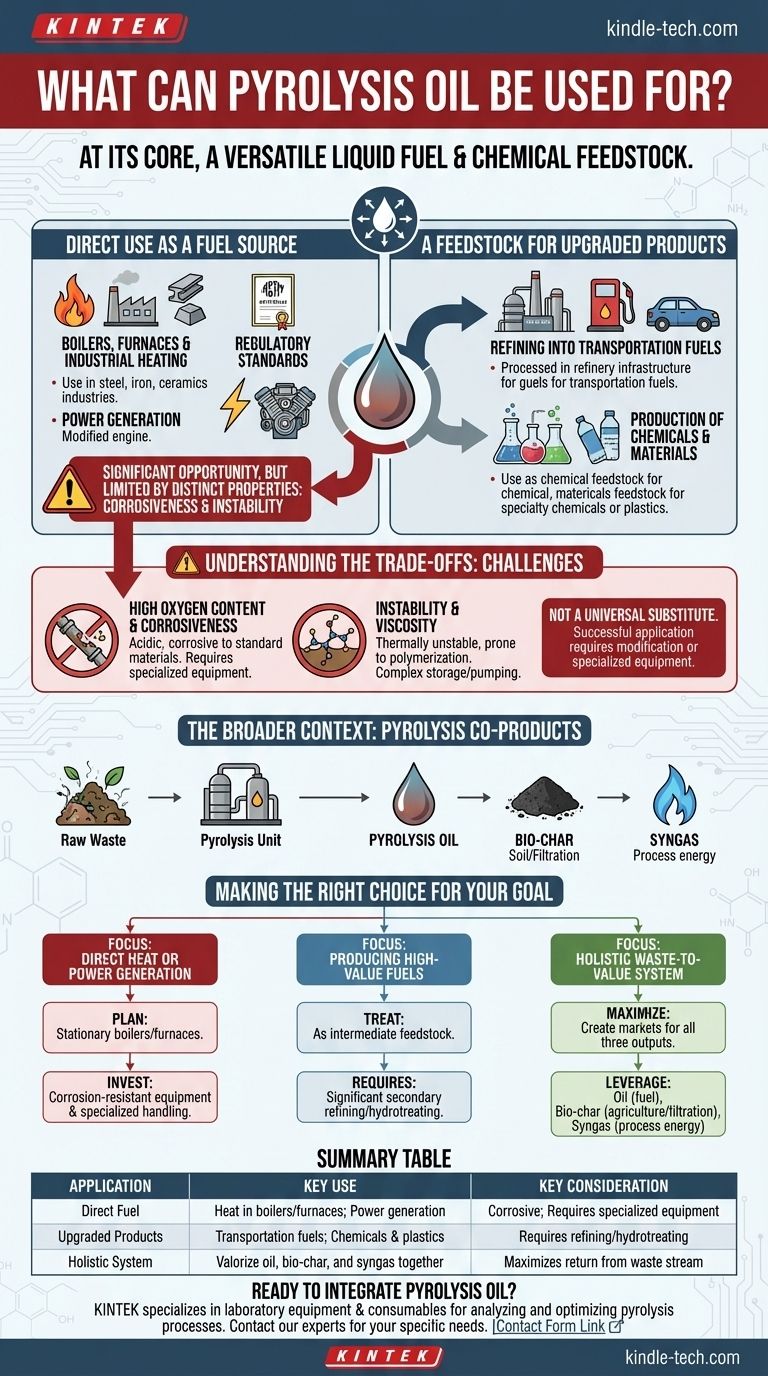

At its core, pyrolysis oil is a versatile liquid fuel and chemical feedstock. It can be used directly for heat and power in industrial settings like boilers and furnaces, or it can be upgraded through refining processes to produce higher-value transportation fuels, chemicals, and other materials.

While pyrolysis oil presents a significant opportunity to convert waste into energy, its direct use is limited by its distinct chemical properties. Understanding these properties—specifically its corrosiveness and instability—is the key to unlocking its true potential.

Direct Use as a Fuel Source

The most immediate application for pyrolysis oil is as a substitute for conventional fuel oil in stationary heat and power generation.

Boilers, Furnaces, and Industrial Heating

Pyrolysis oil can be burned directly for heat in industrial equipment.

Industries such as steel and iron manufacturing, boiler factories, and ceramics production can use it as a primary fuel source, often replacing heavy fuel oil.

Power Generation

The oil can be used as fuel in certain types of engines and power plants to generate electricity.

This includes applications in large power plants and some modified diesel engines or power generation units designed to handle its unique characteristics.

Regulatory Standards

The use of pyrolysis oil as a fuel is governed by established standards.

For example, ASTM D7544 is a standard specification that covers pyrolysis liquid biofuel for stationary applications like industrial burners, ensuring a level of quality and consistency.

A Feedstock for Upgraded Products

Beyond direct combustion, pyrolysis oil serves as a raw material that can be refined into more valuable products.

Refining into Transportation Fuels

While not a simple "drop-in" fuel, pyrolysis oil can be processed within existing refinery infrastructure.

This upgrading process can convert it into more conventional hydrocarbon fuels suitable for transportation.

Production of Chemicals and Materials

The chemical components of pyrolysis oil make it a valuable feedstock for the chemical industry.

It can be used to produce a range of specialty chemicals or as an additive in the creation of products like plastics.

Understanding the Trade-offs: The Challenges of Pyrolysis Oil

To apply pyrolysis oil effectively, you must understand its limitations. Its chemical makeup differs significantly from petroleum-based fuels, presenting several practical challenges.

High Oxygen Content and Corrosiveness

A key differentiator is its high oxygen content, which makes the oil acidic and corrosive to standard pipes and storage tanks.

This property means specialized, corrosion-resistant materials are often required for handling and combustion equipment.

Instability and Viscosity

Pyrolysis oil is thermally unstable and prone to polymerization—thickening and solidifying—when exposed to air or heat over time.

This high viscosity and its general immiscibility with fossil fuels make storage, pumping, and blending a complex engineering problem.

The Need for Specialization

These challenges collectively mean that pyrolysis oil is not a universal substitute for diesel or fuel oil. Its successful industrial application depends on either modifying the oil through upgrading or using specialized equipment designed to handle its properties.

The Broader Context: Pyrolysis Co-products

Pyrolysis oil is just one output of the pyrolysis process. A full understanding includes its valuable co-products.

More Than Just Oil: Bio-char and Syngas

The process also yields bio-char (a solid carbon material) and syngas (a mixture of combustible gases).

Bio-char can be used to amend soil or produce activated carbon, while syngas can be combusted for additional energy generation, contributing to the overall efficiency of the system.

Making the Right Choice for Your Goal

Your intended application will determine how you should approach pyrolysis oil.

- If your primary focus is direct heat or power generation: Plan to use the oil in stationary industrial boilers or furnaces, but be prepared to invest in corrosion-resistant equipment and specialized handling systems.

- If your primary focus is producing high-value fuels: Treat pyrolysis oil as an intermediate feedstock that requires a significant secondary step of hydrotreating or upgrading in a refinery.

- If your primary focus is a holistic waste-to-value system: Maximize your return by creating markets for all three outputs: the oil for fuel, the bio-char for agriculture or filtration, and the syngas for process energy.

By understanding both its potential and its inherent limitations, you can effectively leverage pyrolysis oil as a valuable resource in a circular economy.

Summary Table:

| Application | Key Use | Key Consideration |

|---|---|---|

| Direct Fuel | Heat in boilers/furnaces; Power generation | Corrosive; Requires specialized equipment |

| Upgraded Products | Transportation fuels; Chemicals & plastics | Requires refining/hydrotreating |

| Holistic System | Valorize oil, bio-char, and syngas together | Maximizes return from waste stream |

Ready to integrate pyrolysis oil into your operations? KINTEK specializes in laboratory equipment and consumables for analyzing and developing pyrolysis processes. Whether you are researching fuel properties, testing catalysts for upgrading, or characterizing bio-char, our solutions can help you optimize your waste-to-value system. Contact our experts today to discuss how we can support your specific laboratory needs.

Visual Guide

Related Products

- Customizable Fuel Cell Stack Components for Diverse Applications

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- FS Electrochemical Hydrogen Fuel Cells for Diverse Applications

- High Purity Zinc Foil for Battery Lab Applications

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

People Also Ask

- What are the uses of calcination process? A Guide to Material Transformation

- What equipment is used for calcination? Choosing the Right System for Your Process

- How does pyrolysis help the environment? Transform Waste into Renewable Energy and Carbon Sequestration

- What is the process of pyrolysis waste management? Turn Waste into Valuable Resources

- What is the composition of pyrolysis oil from plastic waste? Unlocking the Potential of Chemical Recycling

- What are the byproducts of biomass gasification? Unlocking Syngas, Biochar, and More

- How is combustion similar to pyrolysis? Unlocking the Thermal Decomposition Pathways

- Is calcination bad for the environment? The Truth About Its Major Carbon Footprint