For melting gold, the best and most widely used crucibles are made from either high-density graphite or a silicon carbide composite. Graphite is favored for its excellent thermal conductivity and resistance to thermal shock, making it ideal for most small-to-medium scale operations. Silicon carbide offers superior durability and a longer lifespan, making it the preferred choice for larger, more industrial applications.

The "best" crucible is not a single material, but one that correctly balances chemical inertness, resistance to extreme temperature changes, and compatibility with your specific heating method. Understanding these principles is key to preventing gold loss and contamination.

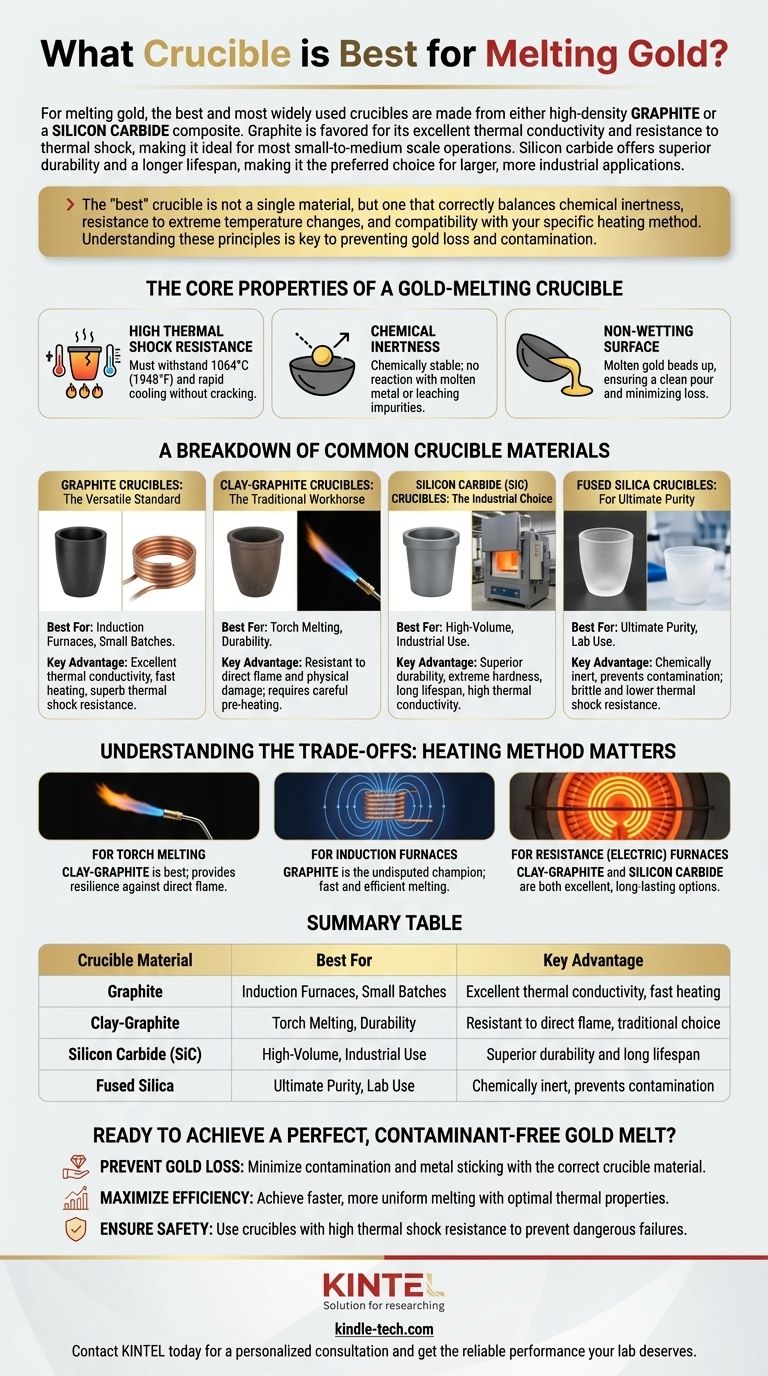

The Core Properties of a Gold-Melting Crucible

To select the right tool, you must first understand the demands of the job. Melting gold subjects a crucible to extreme stress, and only materials with specific properties will succeed.

High Thermal Shock Resistance

A crucible must withstand being heated to over 1064°C (1948°F) and then cooled back down, often rapidly. Materials with poor thermal shock resistance will crack and fail, leading to a dangerous and costly spill of molten metal.

Chemical Inertness

Gold is relatively non-reactive, but at high temperatures, the risk of it leaching impurities from the crucible—or the crucible itself absorbing the gold—increases. A high-quality crucible must be chemically stable and not react with the molten metal.

Non-Wetting Surface

This is a critical property for precious metals. A "non-wetting" surface means the molten gold beads up and does not stick to the crucible walls. This ensures a clean pour and minimizes the amount of valuable metal lost. This is often achieved through a dense material structure or a specialized glaze.

A Breakdown of Common Crucible Materials

While many materials can hold molten metal, only a few are suited for the specific demands of gold.

Graphite Crucibles: The Versatile Standard

High-density, isostatically pressed graphite crucibles are the most common choice for jewelers and small-scale refiners.

Their primary advantage is excellent thermal conductivity, allowing for fast and even heating. This makes them especially effective in induction furnaces, which use magnetic fields to heat the graphite directly. They also have superb resistance to thermal shock.

Clay-Graphite Crucibles: The Traditional Workhorse

These crucibles blend clay (as a binder) with graphite. They are exceptionally durable and more resistant to physical damage and oxidation from direct torch flames than pure graphite.

This makes them a reliable choice for use in gas-fired furnaces or for direct heating with a torch, though they often require a careful pre-heating process to drive out any moisture.

Silicon Carbide (SiC) Crucibles: The Industrial Choice

Silicon carbide is a ceramic composite known for its extreme hardness, strength, and longevity. SiC crucibles can last significantly longer than graphite crucibles under heavy use.

They have high thermal conductivity and excellent resistance to chemical erosion. Their higher cost makes them an investment best suited for larger, high-frequency melting operations where durability is paramount.

Fused Silica Crucibles: For Ultimate Purity

Made from high-purity quartz, these ceramic crucibles are used when avoiding any potential contamination is the absolute top priority.

However, they are more brittle and have lower thermal shock resistance than graphite. They must be heated and cooled very slowly and carefully to prevent cracking, making them better for specific, small-scale laboratory applications rather than general melting.

Understanding the Trade-offs: Heating Method Matters

The way you heat the crucible is as important as the crucible material itself.

For Torch Melting

Using a direct flame puts immense, localized stress on a crucible. A clay-graphite crucible is often the best choice here, as the clay binder provides greater resilience against the oxidizing nature of a direct flame compared to pure graphite. If using pure graphite, ensure it has a protective glaze.

For Induction Furnaces

Graphite crucibles are the undisputed champion for induction heating. The graphite itself becomes the heating element as it interacts with the furnace's magnetic field, leading to extremely fast and efficient melting. Silicon carbide is also effective.

For Resistance (Electric) Furnaces

Most crucible types work well in a resistance furnace, which radiates heat evenly. Your choice will depend more on your budget and the scale of your melts. Clay-graphite and silicon carbide are both excellent, long-lasting options in this environment.

Making the Right Choice for Your Application

There is no single "best" crucible, only the best one for your specific goal. Use this guide to make an informed decision.

- If your primary focus is small-batch melting with a torch: Choose a glazed clay-graphite crucible for its durability and resistance to direct flame.

- If your primary focus is efficiency in an induction furnace: A high-density graphite crucible is the ideal choice for its superior thermal conductivity.

- If your primary focus is longevity and high-volume melting: Invest in a silicon carbide crucible for its exceptional lifespan and strength.

- If your primary focus is achieving the absolute highest purity: Use a fused silica crucible, but be prepared to handle it with extreme care.

Choosing the correct crucible is the foundation of a clean, efficient, and successful melt.

Summary Table:

| Crucible Material | Best For | Key Advantage |

|---|---|---|

| Graphite | Induction Furnaces, Small Batches | Excellent thermal conductivity, fast heating |

| Clay-Graphite | Torch Melting, Durability | Resistant to direct flame, traditional choice |

| Silicon Carbide (SiC) | High-Volume, Industrial Use | Superior durability and long lifespan |

| Fused Silica | Ultimate Purity, Lab Use | Chemically inert, prevents contamination |

Ready to achieve a perfect, contaminant-free gold melt?

The right crucible is critical for protecting your valuable materials and ensuring process efficiency. KINTEK specializes in high-performance lab equipment and consumables, including a full range of crucibles designed for precise melting applications.

We provide the right tools for your specific needs, helping you:

- Prevent Gold Loss: Minimize contamination and metal sticking with the correct crucible material.

- Maximize Efficiency: Achieve faster, more uniform melting with optimal thermal properties.

- Ensure Safety: Use crucibles with high thermal shock resistance to prevent dangerous failures.

Let our experts help you select the ideal crucible for your furnace and application.

Contact KINTEL today for a personalized consultation and get the reliable performance your lab deserves.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- High Purity Pure Graphite Crucible for Evaporation

- Evaporation Crucible for Organic Matter

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

People Also Ask

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What are the disadvantages of DC magnetron sputtering? Key Limitations for Your Lab

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- What is sputtering in plasma treatment? A Guide to High-Purity Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition