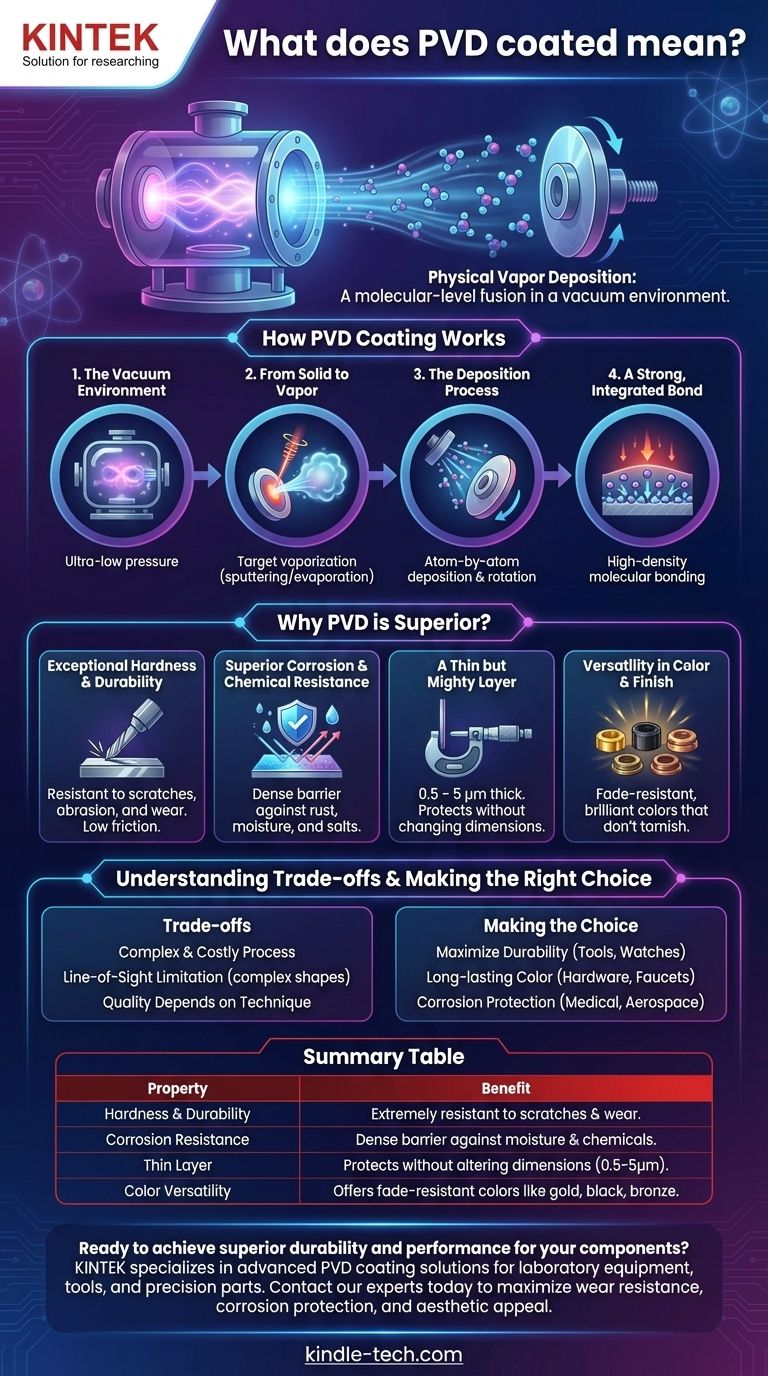

To say a product is PVD coated means it has been treated with Physical Vapor Deposition, a high-tech process performed in a vacuum. During this process, a solid coating material is vaporized into individual atoms or molecules, which then deposit onto the product's surface. This creates an extremely thin, hard, and durable layer that is molecularly bonded to the base material, fundamentally enhancing its properties.

The critical takeaway is that PVD is not like painting or plating; it's a molecular-level fusion. It transforms the surface of an object, giving it superior hardness, wear resistance, and corrosion protection far beyond what traditional coating methods can offer.

How Does PVD Coating Actually Work?

Understanding the process reveals why this coating is so effective. It is a precise, multi-stage operation conducted within a highly controlled environment.

The Vacuum Environment

The entire process must occur in a vacuum chamber at very low pressure. This is essential to remove any air or other particles that could contaminate the coating or interfere with the vaporized atoms as they travel.

From Solid to Vapor

The "Physical Vapor" part of the name refers to how the coating material is prepared. A solid block of the desired material, called a target, is vaporized using methods like sputtering (bombarding it with ions) or evaporation (heating it with an electron beam or electric arc).

The Deposition Process

Once vaporized, these atoms travel through the vacuum chamber and condense onto the object being coated. The object is often carefully rotated to ensure an even, comprehensive layer is deposited across all necessary surfaces, atom by atom.

A Strong, Integrated Bond

This is not a simple layer sitting on top of the surface. Through ion bombardment and high temperatures (often 250°C to 750°C), the coating atoms are embedded into the substrate. This creates a powerful, high-density bond that is exceptionally difficult to chip or flake away.

What Makes a PVD Coating Superior?

The result of this sophisticated process is a finish with a unique combination of desirable properties that are often impossible to achieve with other methods.

Exceptional Hardness and Durability

PVD coatings are extremely hard and have a low coefficient of friction. This makes them incredibly resistant to scratches, abrasion, and daily wear and tear, which is why they are used on everything from cutting tools to luxury watches.

Superior Corrosion and Chemical Resistance

The deposited film is dense and chemically stable. This creates an effective barrier that seals the base material from moisture, salts, and other corrosive agents, preventing rust and tarnish.

A Thin but Mighty Layer

A typical PVD coating is only a few micrometers thick (0.5 – 5 μm). This means it can provide immense protection without changing the dimensions or fine details of the underlying part.

Versatility in Color and Finish

By introducing reactive gases like nitrogen or acetylene into the vacuum chamber, a wide range of compound coatings can be created. This allows for a variety of long-lasting, brilliant colors—such as gold, black, and bronze—that will not fade or tarnish over time.

Understanding the Trade-offs

While highly effective, PVD technology involves certain constraints and complexities that are important to recognize.

The Process is Complex and Costly

PVD requires expensive, specialized vacuum chambers, high-energy sources, and precise controls. This makes it a more premium finishing process compared to simpler methods like painting or electroplating.

It's a Line-of-Sight Process

The vaporized atoms travel in a straight line from the source to the substrate. Coating complex, intricate shapes with hidden surfaces can be challenging and requires sophisticated rotation and positioning of the parts to ensure complete coverage.

Not All PVD is Created Equal

The final quality of the coating depends heavily on the specific PVD technique used, the choice of coating materials, the preparation of the substrate, and the skill of the operator. A poorly executed PVD process will not deliver the expected durability.

Making the Right Choice for Your Goal

When you see "PVD coated" on a product specification, its value depends entirely on your priority.

- If your primary focus is maximum durability and scratch resistance (e.g., tools, high-end watches): PVD is the superior choice, offering a surface hardness that drastically extends the product's pristine appearance and functional life.

- If your primary focus is a specific, long-lasting color finish (e.g., decorative faucets, door hardware): PVD provides vibrant, fade-resistant colors that are bonded to the material, ensuring they won't chip or wear away like paint.

- If your primary focus is corrosion protection in harsh environments (e.g., medical implants, aerospace parts): The dense, chemically inert nature of a PVD coating offers an excellent and reliable protective barrier against chemical attack.

Ultimately, understanding PVD coating moves it from a simple product feature to a clear indicator of superior engineering and long-term value.

Summary Table:

| Property | Benefit |

|---|---|

| Hardness & Durability | Extremely resistant to scratches, abrasion, and wear. |

| Corrosion Resistance | Provides a dense barrier against moisture and chemicals. |

| Thin Layer | Protects without altering the part's dimensions (0.5 – 5 μm). |

| Color Versatility | Offers fade-resistant colors like gold, black, and bronze. |

Ready to achieve superior durability and performance for your components? KINTEK specializes in advanced PVD coating solutions for laboratory equipment, tools, and precision parts. Our expertise ensures a molecular-level bond that maximizes wear resistance, corrosion protection, and aesthetic appeal. Contact our experts today to discuss how our PVD coatings can add long-term value to your products.

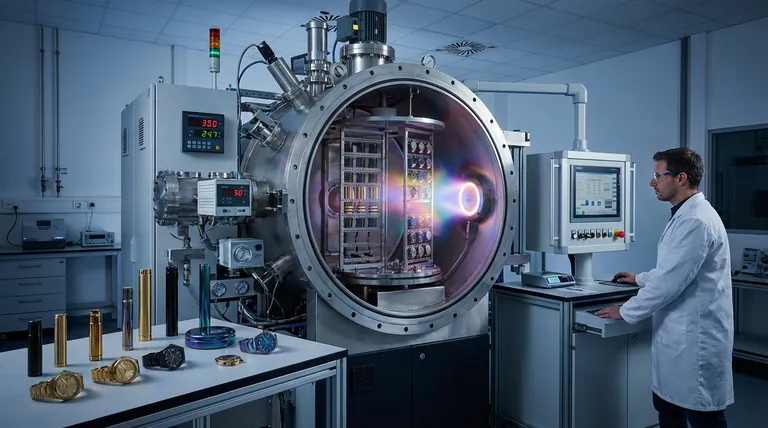

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages and disadvantages of hot stamping? Unlock Ultra-High Strength for Automotive Parts

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is the main function of hot press forming? Achieve Superior Strength & Precision in Manufacturing