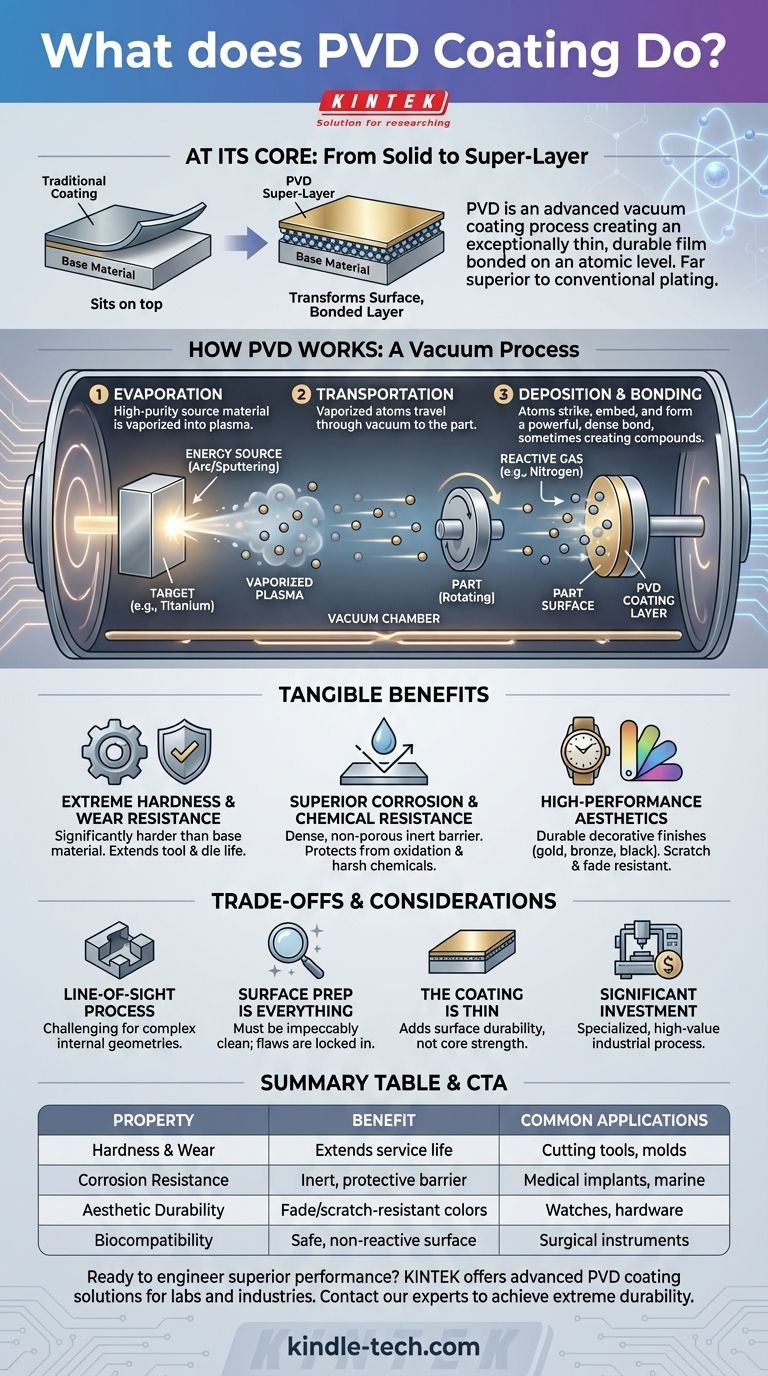

At its core, Physical Vapor Deposition (PVD) is an advanced vacuum coating process used to apply an exceptionally thin but extremely durable film onto a material's surface. This process fundamentally enhances the part's properties—making it harder, more resistant to wear and corrosion, or giving it a specific color—by bonding a new layer of metal or ceramic to it on an atomic level.

While traditional coatings simply sit on top of a surface, PVD transforms the surface itself. It uses a high-energy, atom-by-atom deposition in a vacuum to create a bonded layer that is far superior in durability and performance compared to conventional plating or painting.

How PVD Works: From Solid to Super-Layer

The PVD process might sound complex, but it's based on a logical sequence of physical principles. It all takes place inside a sealed, high-vacuum chamber to ensure absolute purity and control.

The Critical Vacuum Environment

The entire process is performed under a vacuum for two key reasons. First, it removes all other atoms and contaminants that could interfere with the coating. Second, it allows atoms from the coating material to travel directly to the part without colliding with air molecules.

Step 1: Evaporation

A solid, high-purity source material—known as a "target"—is placed inside the chamber. This target can be a metal like titanium, zirconium, or chromium. Using a high-energy method like a high-voltage arc or sputtering, this solid material is vaporized into a plasma of its own atoms.

Step 2: Transportation

These vaporized atoms travel through the vacuum chamber and toward the part to be coated. The components are carefully positioned and often rotated on fixtures to ensure the vapor stream reaches all necessary surfaces evenly.

Step 3: Deposition and Bonding

When the high-energy vapor atoms strike the part's surface, they don't just stick; they embed and form a powerful, dense bond with the substrate. This happens atom by atom, building a thin film that is an integral part of the surface.

To create specific coating types (like the common gold-colored Titanium Nitride), a reactive gas like nitrogen is introduced into the chamber. This gas reacts with the metal vapor (titanium) as it deposits, forming a new ceramic compound on the part's surface.

The Tangible Benefits of a PVD Coating

Applying a layer that is often thinner than a human hair results in dramatic improvements to the underlying part.

Extreme Hardness and Wear Resistance

PVD coatings are exceptionally hard, often significantly harder than the base material. This makes them the standard for protecting cutting tools, dies, and molds from the friction and abrasion of industrial use, vastly extending their service life.

Superior Corrosion and Chemical Resistance

The deposited film is dense and non-porous, creating an inert barrier that protects the substrate from oxidation, salt spray, and chemical attack. This is critical for parts used in harsh environments or for medical implants.

High-Performance Aesthetics

Beyond its functional benefits, PVD is a premier process for creating durable decorative finishes. It can produce a wide spectrum of colors (black, graphite, gold, bronze) that are far more resistant to scratching and fading than traditional electroplating or paint.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Line-of-Sight Process

The vaporized atoms travel in a straight line. This means that coating complex internal geometries or deep, narrow holes can be challenging. Proper fixturing and part rotation are essential to achieve uniform coverage.

Surface Preparation is Everything

A PVD coating is only as good as the surface it is applied to. The underlying part must be impeccably clean and free of any oils, oxides, or imperfections. Any surface flaw will be locked in—and potentially amplified—by the coating process.

The Coating is Thin

PVD adds incredible surface durability, but it does not change the core strength of the part. A deep gouge or a heavy impact that deforms the underlying material can still breach the thin PVD layer.

It Requires Significant Investment

PVD coating equipment is highly specialized and operates under precise conditions. This makes it a high-value industrial process rather than a simple workshop technique, reflected in its cost and suitability for high-performance or high-volume applications.

Is PVD the Right Choice for Your Application?

To decide if PVD is the correct approach, consider your primary goal for the component.

- If your primary focus is extending tool life and performance: PVD is the industry standard for creating hard, low-friction surfaces on cutting tools, punches, and molds.

- If your primary focus is a decorative finish with maximum durability: PVD offers a range of rich, stable colors for items like watches, faucets, and hardware that far outlasts traditional plating.

- If your primary focus is biocompatibility and chemical resistance: PVD creates an inert, protective layer essential for medical implants and components exposed to harsh environments.

Ultimately, PVD coating provides a way to engineer a material's surface for performance that the bulk material alone could never achieve.

Summary Table:

| Key Property | PVD Coating Benefit | Common Applications |

|---|---|---|

| Hardness & Wear | Extends service life significantly | Cutting tools, molds, industrial parts |

| Corrosion Resistance | Creates an inert, protective barrier | Medical implants, marine components |

| Aesthetic Durability | Provides fade and scratch-resistant colors | Watches, architectural hardware, faucets |

| Biocompatibility | Forms a safe, non-reactive surface | Surgical instruments, medical devices |

Ready to engineer superior performance into your components?

KINTEK's advanced PVD coating solutions are designed for laboratories and industries that demand the highest standards in material science. Whether you're developing longer-lasting cutting tools, biocompatible medical implants, or durable decorative finishes, our expertise ensures a coating that transforms your material's surface properties.

We specialize in providing the lab equipment and consumables needed for precise, high-quality PVD processes. Contact our experts today to discuss how we can help you achieve extreme durability and performance for your specific application.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process