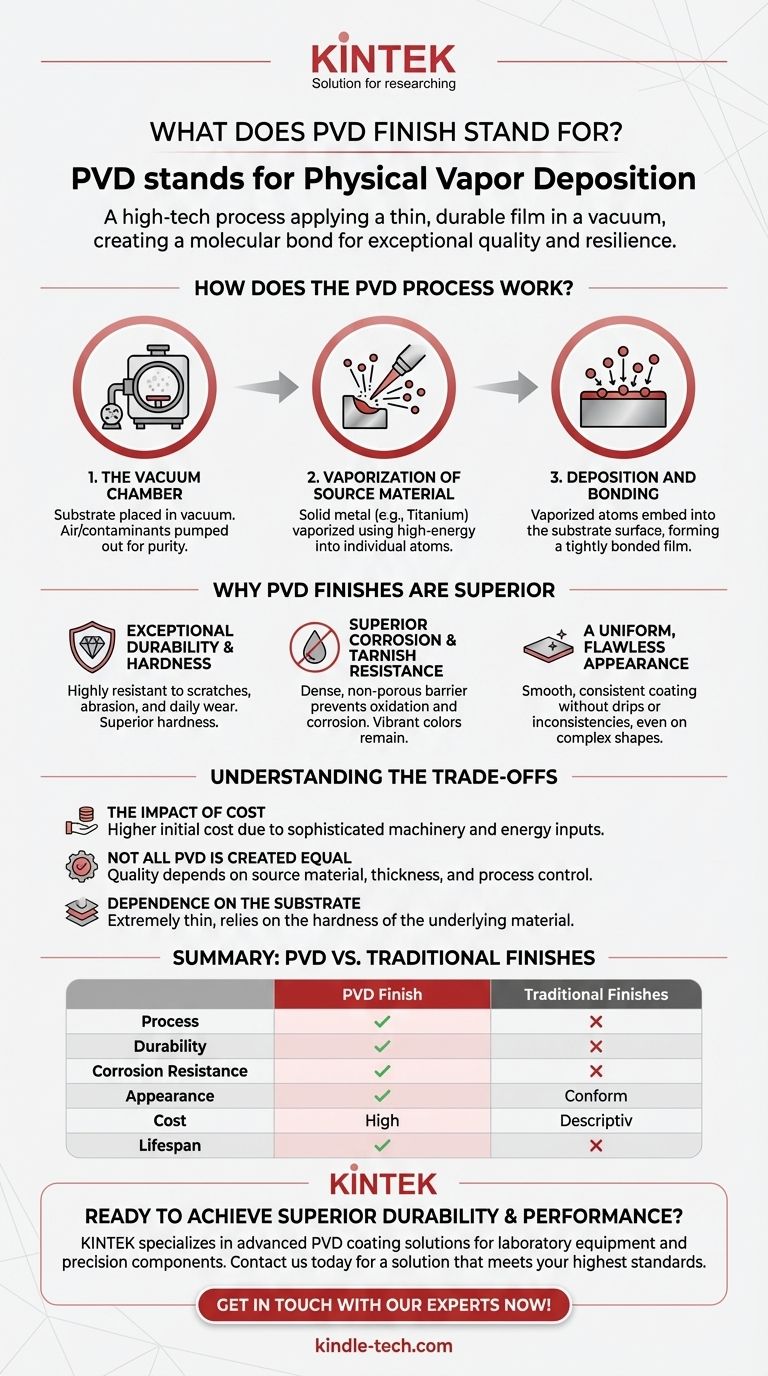

PVD stands for Physical Vapor Deposition. It is a state-of-the-art finishing process where a thin, durable film is applied to a surface in a high-tech vacuum environment. Unlike traditional plating or painting, PVD molecularly bonds the coating to the object, resulting in a finish of exceptional quality and resilience.

Physical Vapor Deposition is not a type of material but a sophisticated process. It transforms a solid metal into a vapor that bonds to a target object atom-by-atom, creating a surface finish that is significantly harder, more corrosion-resistant, and more durable than conventional coatings.

How Does the PVD Process Actually Work?

To understand why a PVD finish is superior, it’s helpful to understand the core principles of the process. It occurs in a highly controlled environment and involves three fundamental stages.

The Vacuum Chamber

First, the object to be coated (the substrate) is placed into a vacuum chamber. All the air and contaminants are pumped out, which is critical for ensuring the purity and adhesion of the final coating.

Vaporization of the Source Material

Next, a solid source material—often a durable metal like titanium, zirconium, or chromium—is vaporized. This is done using a high-energy source, such as an electron beam, that bombards the material and transforms it into a plasma or vapor of individual atoms.

Deposition and Bonding

Finally, these vaporized atoms are deposited onto the substrate. Because of the energy involved and the vacuum environment, the atoms embed themselves into the surface of the object, forming a new, thin, and tightly bonded film. This isn't a layer of paint sitting on top; it's an integrated part of the surface.

Why PVD Finishes Are Superior

The unique nature of the PVD process imparts qualities that traditional methods struggle to match. These benefits are why PVD is used on everything from luxury watches and kitchen faucets to industrial drill bits.

Exceptional Durability and Hardness

The primary advantage of a PVD finish is its hardness. The molecular bond creates a surface that is highly resistant to scratches, abrasion, and daily wear and tear. A PVD-coated faucet, for example, will resist minor scratches from cleaning far better than a simple chrome-plated one.

Superior Corrosion and Tarnish Resistance

The thin film created by PVD is dense and non-porous. This provides a robust barrier against oxidation and corrosion. Finishes like PVD brass or gold will not tarnish over time, and the underlying material is protected from moisture and chemicals.

A Uniform, Flawless Appearance

The atom-by-atom deposition process ensures a completely uniform and smooth coating, even on complex shapes. This results in a flawless aesthetic without the drips, inconsistencies, or weak spots that can occur with painting or dipping methods.

Understanding the Trade-offs

While PVD offers remarkable performance, it is important to understand its context. No technology is without its considerations.

The Impact of Cost

The PVD process requires sophisticated machinery, a vacuum environment, and high energy inputs. This makes it a more expensive finishing method compared to traditional electroplating or powder coating. The added cost is a direct trade-off for the dramatic increase in durability.

Not All PVD Is Created Equal

The final quality of a PVD finish depends on the source material used, the thickness of the coating, and the quality control of the process. A cheap PVD application may not offer the same longevity as one from a reputable manufacturer using high-grade materials.

Dependence on the Substrate

A PVD coating is incredibly thin—often only a few microns thick. While it is very hard, it relies on the hardness of the material underneath it. A PVD finish on a soft metal can still be dented, though the surface itself will resist scratching.

Choosing the Right Finish for Your Needs

Understanding PVD empowers you to look past marketing terms and evaluate a product based on its fundamental technology. Use these points to guide your decision.

- If your primary focus is maximum durability and longevity: A PVD finish is the clear choice for items in high-use environments like kitchens, bathrooms, or on tools.

- If your primary focus is resisting tarnish and corrosion: PVD is ideal for decorative items and fixtures, ensuring the color and shine remain vibrant for years without polishing.

- If your primary focus is the lowest possible cost: Traditional chrome plating or powder coating might be more budget-friendly, but you must accept the compromise in long-term durability and scratch resistance.

Ultimately, choosing a product with a PVD finish is an investment in superior performance and a longer lifespan.

Summary Table:

| Aspect | PVD Finish | Traditional Finishes (e.g., Chrome Plating) |

|---|---|---|

| Process | Atom-by-atom deposition in a vacuum | Electrochemical plating or painting |

| Durability | Extremely hard, scratch & abrasion resistant | Less durable, prone to scratching & wear |

| Corrosion Resistance | Excellent, non-porous barrier | Good, but can be porous and less effective |

| Appearance | Uniform, flawless, even on complex shapes | Can have inconsistencies, drips, or weak spots |

| Cost | Higher initial cost | Lower initial cost |

| Lifespan | Very long-lasting | Shorter lifespan |

Ready to achieve superior durability and performance for your products?

At KINTEK, we specialize in advanced PVD coating solutions for laboratory equipment and precision components. Our state-of-the-art PVD processes ensure your products are equipped with a finish that is exceptionally hard, corrosion-resistant, and long-lasting—enhancing both their performance and lifespan.

Contact us today to discuss how our PVD expertise can benefit your specific application. Let's create a coating solution that meets your highest standards for quality and durability.

Get in touch with our experts now!

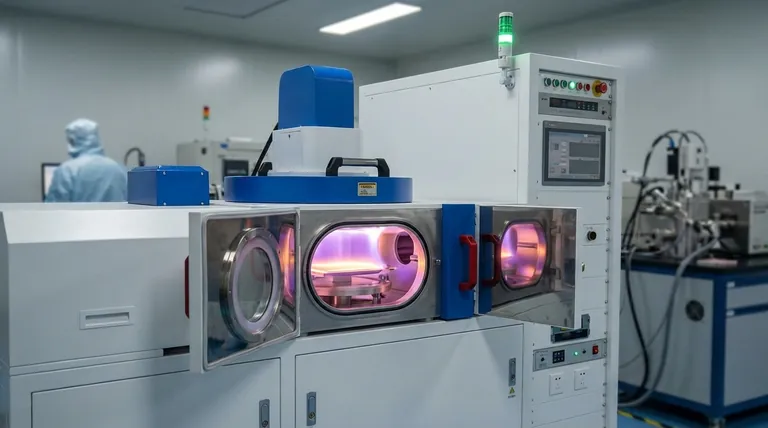

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition