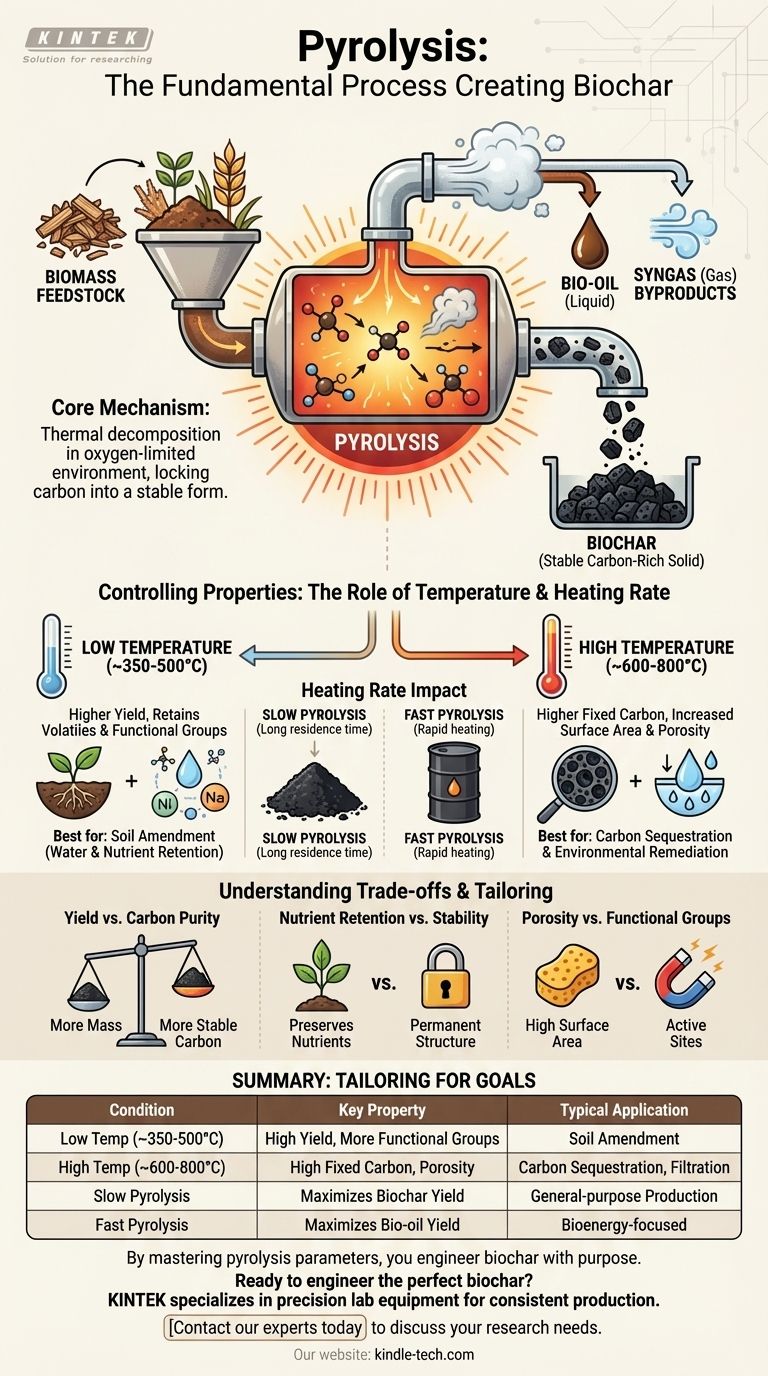

To be precise, pyrolysis is not a process that does something to biochar; it is the fundamental process that creates biochar. It involves heating organic materials, known as biomass, to high temperatures in an environment with little to no oxygen. This controlled thermal decomposition breaks down the complex structures of the biomass into a stable, carbon-rich solid (biochar), along with liquid (bio-oil) and gas (syngas) byproducts.

The core concept to understand is that pyrolysis isn't just a switch you flip to make biochar. Instead, the specific conditions of the pyrolysis process—primarily temperature and heating rate—are the control knobs that determine the final physical and chemical properties of the biochar itself.

The Core Mechanism: From Biomass to Biochar

To understand the product, you must first understand the process. Pyrolysis systematically deconstructs organic matter, locking carbon into a new, stable form.

What is Pyrolysis?

Pyrolysis is thermal decomposition in an oxygen-limited environment. By preventing the biomass from combusting (burning), the process breaks down large organic molecules into smaller, more stable components instead of turning them into ash and carbon dioxide.

The Starting Material: Biomass

The process begins with biomass, which is any organic material such as wood chips, crop residues, manure, or even food waste. The type of biomass used, or feedstock, has a significant influence on the mineral and nutrient content of the final biochar.

The Chemical Transformation

As biomass is heated, its main components—cellulose, hemicellulose, and lignin—break down. Water and volatile compounds are driven off, and the remaining carbon atoms rearrange into stable aromatic structures. This is what concentrates the carbon and creates the skeletal structure of biochar.

How Pyrolysis Conditions Define Biochar's Properties

Controlling the pyrolysis process is how you engineer biochar for a specific purpose. Temperature is the single most important variable.

The Critical Role of Temperature

The final temperature reached during pyrolysis directly dictates the biochar's characteristics. There is a clear relationship between temperature and the resulting properties.

Low-Temperature Biochar (~350-500°C)

Biochar produced at lower temperatures generally has a higher yield (more of the original biomass mass is retained). It also retains more volatile matter and oxygen-containing functional groups on its surface, which can be beneficial for holding nutrients and water in soil.

High-Temperature Biochar (~600-800°C)

As pyrolysis temperature increases, the biochar yield decreases, but the resulting product becomes more refined. High-temperature biochar has a higher percentage of fixed carbon, greater surface area, and increased porosity. This makes it more stable for long-term carbon sequestration and more effective for applications like water filtration.

The Impact of Heating Rate

The speed at which the biomass is heated also changes the outcome.

- Slow Pyrolysis: A slow heating rate with a long residence time maximizes the yield of the solid biochar.

- Fast Pyrolysis: A very rapid heating rate maximizes the production of the liquid bio-oil, with biochar being a secondary product.

Understanding the Trade-offs

Choosing pyrolysis parameters always involves balancing competing priorities. There is no single "best" biochar, only the best biochar for a specific application.

Yield vs. Carbon Purity

Low-temperature pyrolysis gives you more biochar by mass, but it contains less pure, stable carbon. High-temperature pyrolysis creates a more carbon-dense and stable product, but you get less of it from the same amount of starting biomass.

Nutrient Retention vs. Stability

Lower temperatures are better at preserving some of the nutrient-holding chemical structures from the original biomass. Higher temperatures create a more permanent structure for carbon sequestration but can volatilize some nutrients like nitrogen and sulfur.

Porosity vs. Functional Groups

High-temperature biochar is highly porous, making it like a physical sponge for water and microbes. Low-temperature biochar has more chemically active sites (functional groups) on its surface, making it more like a chemical magnet for certain nutrients.

Tailoring Pyrolysis for Your Specific Goal

By understanding these principles, you can select or produce biochar with the right characteristics for your needs.

- If your primary focus is agricultural soil amendment: Choose a biochar made via slow pyrolysis at lower temperatures (350-550°C) to maximize water retention and nutrient-holding capacity.

- If your primary focus is long-term carbon sequestration: Use biochar produced at high temperatures (>600°C) to ensure the carbon is in its most stable form and will resist decomposition for centuries.

- If your primary focus is environmental remediation (e.g., filtering contaminants): Opt for high-temperature biochar for its high surface area and porosity, which are ideal for adsorbing pollutants.

By mastering the parameters of pyrolysis, you move from simply making biochar to engineering it with purpose.

Summary Table:

| Pyrolysis Condition | Key Biochar Property | Typical Application |

|---|---|---|

| Low Temperature (~350-500°C) | Higher yield, more functional groups | Soil amendment for nutrient/water retention |

| High Temperature (~600-800°C) | Higher fixed carbon, greater surface area/porosity | Carbon sequestration, water filtration |

| Slow Pyrolysis | Maximizes solid biochar yield | General-purpose biochar production |

| Fast Pyrolysis | Maximizes liquid bio-oil yield | Bioenergy-focused production |

Ready to engineer the perfect biochar for your application?

KINTEK specializes in precision lab equipment, including pyrolysis reactors, to help you control temperature and heating rate for consistent, high-quality biochar production. Whether your goal is soil enhancement, carbon sequestration, or environmental remediation, our solutions are designed for your laboratory's needs.

Contact our experts today to discuss how we can support your biochar research and development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds