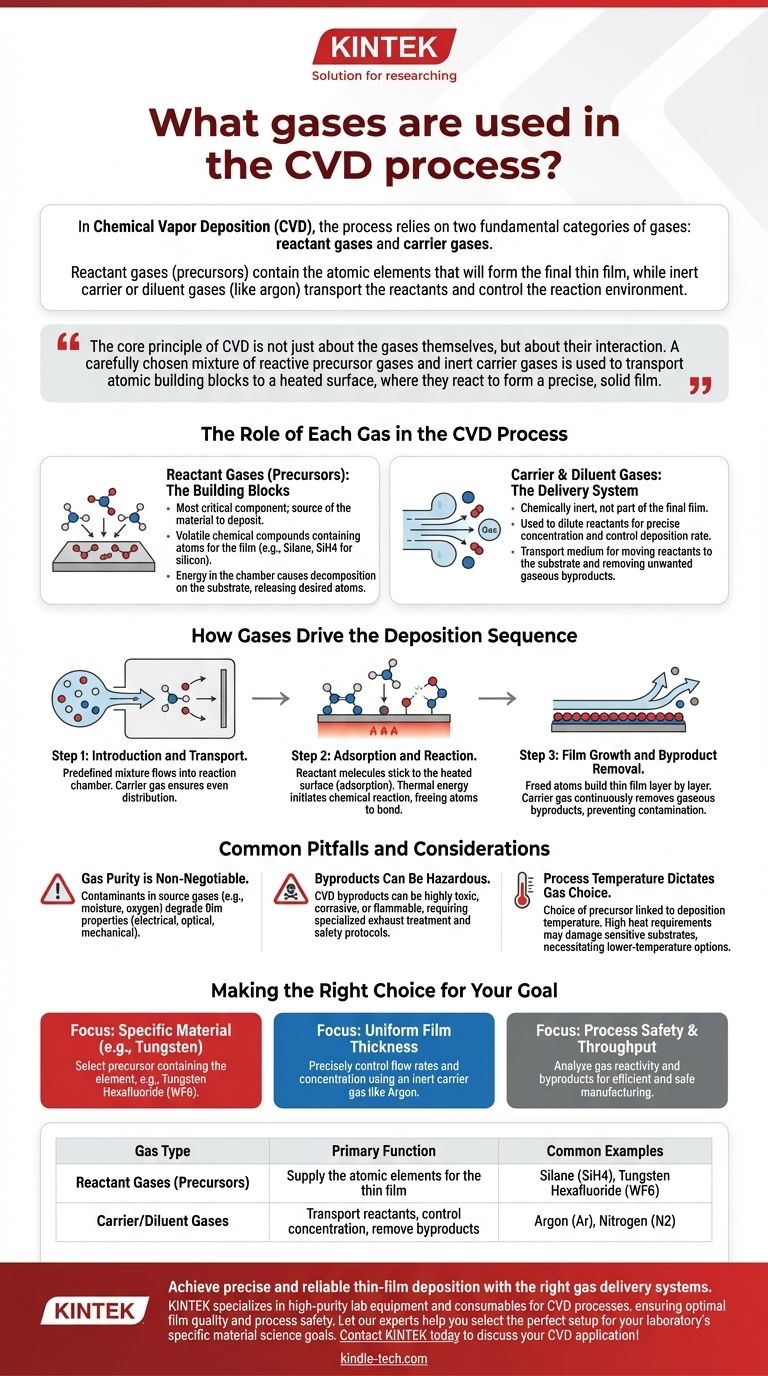

In Chemical Vapor Deposition (CVD), the process relies on two fundamental categories of gases: reactant gases and carrier gases. Reactant gases, often called precursors, contain the atomic elements that will form the final thin film, while inert carrier or diluent gases, like argon, are used to transport the reactants and control the reaction environment.

The core principle of CVD is not just about the gases themselves, but about their interaction. A carefully chosen mixture of reactive precursor gases and inert carrier gases is used to transport atomic building blocks to a heated surface, where they react to form a precise, solid film.

The Role of Each Gas in the CVD Process

To understand CVD, you must see the gases as performing distinct, cooperative jobs. The process is akin to an automated assembly line where one set of gases delivers the raw materials and another facilitates the entire operation.

Reactant Gases (Precursors): The Building Blocks

The reactant gas is the most critical component, as it is the source of the material you intend to deposit.

These gases are chemical compounds that are volatile (easily evaporated) and contain the atoms that will form the film. For example, to deposit a silicon film, Silane (SiH4) is a common reactant gas.

When introduced into the high-temperature reaction chamber, the energy causes these precursor molecules to decompose or react on the substrate surface, releasing the desired atoms.

Carrier & Diluent Gases: The Delivery System

Carrier gases are chemically inert and do not become part of the final film. Their primary role is to manage the process.

These gases, such as Argon (Ar) or Nitrogen (N2), are used to dilute the reactant gases to a precise concentration. This is essential for controlling the deposition rate.

They also act as the transport medium, creating the gas flow that moves the reactant molecules to the substrate and, just as importantly, carries away the unwanted gaseous byproducts from the chemical reaction.

How Gases Drive the Deposition Sequence

The references outline a clear, multi-step process. The gas mixture is the engine that drives every single step.

Step 1: Introduction and Transport

A predefined mixture of reactant and carrier gases flows into the reaction chamber. The carrier gas ensures the reactants are distributed evenly as they approach the substrate.

Step 2: Adsorption and Reaction

Once the gas molecules reach the heated substrate, the reactant molecules stick to the surface (a process called adsorption). The thermal energy of the substrate breaks their chemical bonds.

This initiates the chemical reaction on the surface, freeing the desired atoms (e.g., silicon from silane) to bond with the substrate.

Step 3: Film Growth and Byproduct Removal

The freed atoms arrange themselves into a crystalline or amorphous solid layer, building the thin film one atomic layer at a time.

Simultaneously, the other atoms from the original reactant gas form gaseous byproducts (e.g., hydrogen gas from silane). The continuous flow of the carrier gas efficiently removes these byproducts from the chamber, preventing contamination of the film.

Common Pitfalls and Considerations

Selecting the right gases involves critical trade-offs that directly impact the quality of the film and the safety of the operation.

Gas Purity is Non-Negotiable

The references mention contaminants. Even minuscule impurities in the source gases, like moisture or oxygen, can be incorporated into the growing film, severely degrading its electrical, optical, or mechanical properties.

Byproducts Can Be Hazardous

Careful consideration must be given to the reaction byproducts. Many CVD processes produce highly toxic, corrosive, or flammable gases that require specialized exhaust treatment and safety protocols.

Process Temperature Dictates Gas Choice

The choice of precursor gas is fundamentally linked to the required deposition temperature. Some precursors require very high heat to react, which can damage sensitive substrates. This creates a constant search for lower-temperature precursors that still yield high-quality films.

Making the Right Choice for Your Goal

Your selection of gases must be directly tied to the specific outcome you need to achieve for your material or device.

- If your primary focus is depositing a specific material (e.g., Tungsten): You must select a reactant precursor gas that contains that element, such as Tungsten Hexafluoride (WF6).

- If your primary focus is achieving a uniform film thickness: You need to precisely control the flow rates and concentration using an inert carrier gas like Argon to ensure even delivery of the reactant.

- If your primary focus is process safety and throughput: You must analyze the reactivity of your chosen gases and the nature of their byproducts to design an efficient and safe manufacturing environment.

Ultimately, the deliberate and precise control of these gases is what transforms a simple chemical reaction into a powerful tool for engineering materials at the atomic scale.

Summary Table:

| Gas Type | Primary Function | Common Examples |

|---|---|---|

| Reactant Gases (Precursors) | Supply the atomic elements for the thin film | Silane (SiH4), Tungsten Hexafluoride (WF6) |

| Carrier/Diluent Gases | Transport reactants, control concentration, remove byproducts | Argon (Ar), Nitrogen (N2) |

Achieve precise and reliable thin-film deposition with the right gas delivery systems. KINTEK specializes in high-purity lab equipment and consumables for CVD processes, ensuring optimal film quality and process safety. Let our experts help you select the perfect setup for your laboratory's specific material science goals. Contact KINTEK today to discuss your CVD application!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries