The choice of grinding media is fundamental to the performance of a ball mill. The materials used range from high-density metals to inert ceramics, including steel balls, tungsten carbide, various ceramics like zirconium oxide, and natural stones such as agate and flint pebbles. Each material is selected based on the specific requirements of the grinding process.

The selection of a grinding medium is not arbitrary; it is a critical decision that balances the need for grinding efficiency against concerns about cost and product contamination. The ideal medium is harder than the material being ground, dense enough to provide sufficient impact energy, and chemically inert for the specific application.

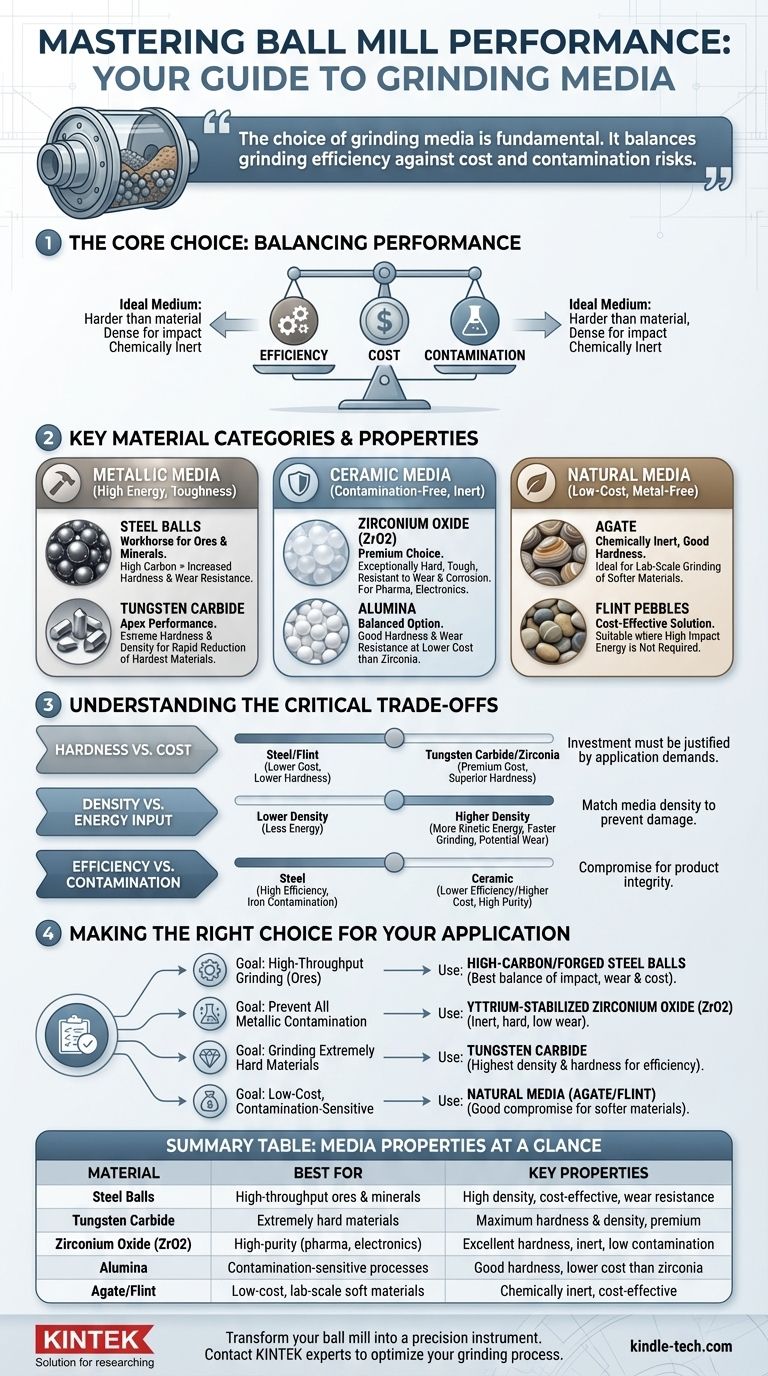

Key Material Categories and Their Properties

The function of grinding media is to crush material through impact and attrition. This is achieved by lifting the media along the wall of the rotating mill drum and then allowing it to fall onto the material below. The characteristics of the media directly dictate the efficiency and outcome of this process.

Metallic Media (Steel & Tungsten Carbide)

Metallic media is prized for its high density and toughness, making it ideal for high-energy applications.

Steel balls, typically made from high-carbon or forged steel alloys, are the workhorse for grinding tough, abrasive materials like ores and minerals. Increasing the carbon content enhances both hardness and wear resistance, prolonging the media's life.

Tungsten carbide represents the apex of metallic media in terms of performance. Its extreme hardness and density—significantly higher than steel—provide maximum impact energy, enabling the rapid size reduction of even the hardest materials.

Ceramic Media (Zirconia & Alumina)

Ceramic media is the solution when preventing metallic contamination is a top priority.

Yttrium-stabilized Zirconium Oxide (ZrO2) is a premium ceramic medium. It is exceptionally hard, tough, and highly resistant to wear and corrosion. These properties make it the preferred choice for wet grinding and for applications in electronics, pharmaceuticals, and advanced materials where purity is paramount.

Alumina (Aluminum Oxide) is another common ceramic that offers good hardness and wear resistance at a lower cost than zirconia, providing a balanced option for many contamination-sensitive processes.

Natural Media (Agate & Flint)

Natural stones offer a low-cost, metal-free grinding solution.

Agate is a form of microcrystalline quartz that is chemically inert and has good hardness. It is often used in laboratory-scale mills to prevent contamination when grinding relatively soft materials.

Flint pebbles have been used for centuries as a cost-effective grinding medium. While less dense and durable than steel or advanced ceramics, they are suitable for applications where cost is a primary driver and high impact energy is not required.

Understanding the Trade-offs

Choosing the right media involves navigating a series of critical trade-offs. An incorrect choice can lead to inefficient grinding, damage to the equipment, or contamination of the final product.

Hardness vs. Cost

The hardness of the media must be greater than that of the material being milled. While materials like tungsten carbide and zirconia offer superior hardness and wear resistance, their cost is significantly higher than steel or flint. The investment must be justified by the application's demands.

Density vs. Energy Input

Higher density media delivers more kinetic energy upon impact, resulting in faster and more efficient grinding. However, this high energy can also fracture delicate materials or cause excessive wear on the mill jar itself. A proper match between media density and the application is essential.

Efficiency vs. Contamination

Steel balls are highly efficient and cost-effective but will inevitably introduce small amounts of iron into the milled product. For bulk processes like ore grinding, this is acceptable. For high-purity applications, the lower efficiency or higher cost of a ceramic medium is a necessary compromise to ensure product integrity.

Making the Right Choice for Your Application

Your selection should be guided by a clear understanding of your material, your process, and your desired outcome.

- If your primary focus is high-throughput grinding of hard materials (like ores): High-carbon or forged steel balls offer the best balance of impact, wear resistance, and cost.

- If your primary focus is preventing all metallic contamination: Yttrium-stabilized Zirconium Oxide (ZrO2) is the superior choice due to its inertness, hardness, and low wear rate.

- If your primary focus is grinding extremely hard or tough materials: Tungsten carbide provides the highest density and hardness, enabling the most efficient size reduction, albeit at a premium cost.

- If your primary focus is a low-cost, contamination-sensitive application: Natural media like agate or flint pebbles provide a good compromise when the performance of advanced ceramics isn't necessary.

Ultimately, selecting the right grinding media transforms your ball mill from a simple machine into a precision instrument tailored to your specific goal.

Summary Table:

| Material | Best For | Key Properties |

|---|---|---|

| Steel Balls | High-throughput grinding of ores & minerals | High density, cost-effective, high wear resistance |

| Tungsten Carbide | Grinding extremely hard materials | Maximum hardness & density, premium performance |

| Zirconium Oxide (ZrO2) | High-purity applications (pharma, electronics) | Excellent hardness, inert, low contamination |

| Alumina | Contamination-sensitive processes | Good hardness, lower cost than zirconia |

| Agate/Flint | Low-cost, lab-scale grinding of soft materials | Chemically inert, cost-effective |

Transform your ball mill into a precision instrument. Selecting the perfect grinding media is critical for your lab's efficiency and product purity. KINTEK specializes in high-performance lab equipment and consumables, providing expert guidance to match your specific application needs.

Contact our experts today to discuss your grinding media requirements and ensure optimal results for your laboratory processes.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab