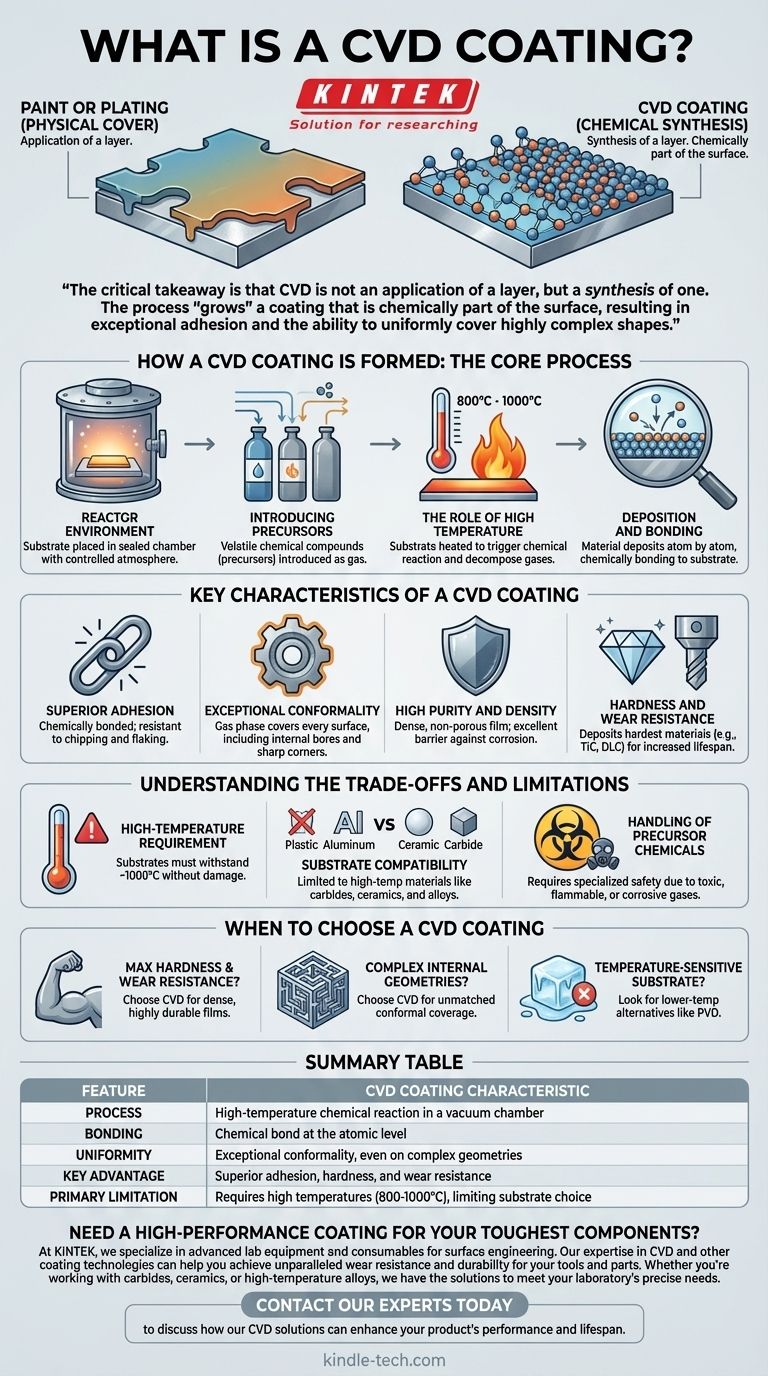

In essence, a CVD coating is a highly durable, thin film of material grown onto a surface through a high-temperature chemical process. Unlike a paint or plating that simply covers a surface, Chemical Vapor Deposition (CVD) involves introducing reactive gases into a vacuum chamber, where heat causes them to decompose and form a new, solid layer that chemically bonds directly to the substrate at an atomic level.

The critical takeaway is that CVD is not an application of a layer, but a synthesis of one. The process "grows" a coating that is chemically part of the surface, resulting in exceptional adhesion and the ability to uniformly cover highly complex shapes.

How a CVD Coating is Formed: The Core Process

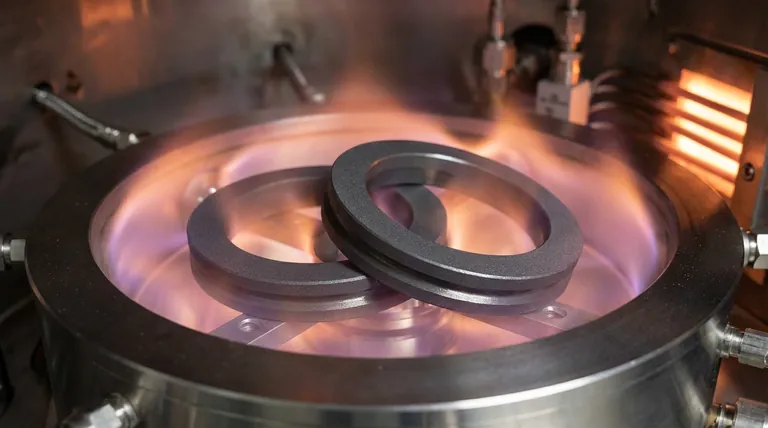

To understand a CVD coating's properties, you must first understand how it is created. The process occurs within a specialized piece of equipment called a CVD reactor.

The Reactor Environment

The process begins by placing the component, or substrate, inside a sealed chamber. The atmosphere is tightly controlled, often by creating a vacuum and then backfilling it with specific gases.

Introducing the Precursors

Volatile chemical compounds, known as precursors, are then introduced into the chamber in a gaseous state. These precursors are carefully selected to contain the atomic elements required for the final coating material. For example, to create Titanium Nitride (TiN), precursors like Titanium Tetrachloride (TiCl4) and Nitrogen (N2) are used.

The Role of High Temperature

The substrate is heated to extremely high temperatures, often between 800°C and 1000°C. This intense heat provides the energy needed to trigger a chemical reaction or break down the precursor gases.

Deposition and Bonding

As the precursor gases react near the hot substrate, they form the desired solid coating material. This material deposits atom by atom onto the surface, creating a thin, dense, and uniform film that is chemically bonded to the substrate itself.

Key Characteristics of a CVD Coating

The unique manufacturing process gives CVD coatings a distinct set of advantages that make them ideal for demanding applications.

Superior Adhesion

Because the coating is chemically bonded rather than physically layered, its adhesion to the substrate is exceptionally strong. This makes it highly resistant to chipping, flaking, or delamination.

Exceptional Conformality

Since the process relies on a gas phase, the precursor molecules can reach every exposed surface of a component before reacting. This allows CVD to create a perfectly uniform coating on complex geometries, including internal bores, threads, and sharp corners.

High Purity and Density

The controlled chemical reaction produces an extremely pure and dense film. Unlike some other methods, this process results in a non-porous coating that provides an excellent barrier against corrosion and wear.

Hardness and Wear Resistance

CVD is used to deposit some of the hardest known materials, such as Titanium Carbide (TiC) and Diamond-Like Carbon (DLC). These coatings dramatically increase the surface hardness and lifespan of tools and components subjected to friction and abrasion.

Understanding the Trade-offs and Limitations

While powerful, the CVD process is not universally applicable. Its primary limitations stem directly from the conditions required for deposition.

The High-Temperature Requirement

The single greatest constraint of CVD is heat. Substrates must be able to withstand temperatures up to 1000°C without melting, warping, or undergoing undesirable changes in their material properties (e.g., losing their temper).

Substrate Compatibility

This high-temperature requirement immediately rules out many materials, such as plastics, aluminum alloys, and many tempered steels. The process is typically reserved for materials like carbides, ceramics, and high-temperature steel alloys.

Handling of Precursor Chemicals

The gases used as precursors are often toxic, flammable, or corrosive. This necessitates specialized, high-cost facilities with advanced safety and handling protocols, distinguishing it from processes that can be run in a more standard industrial environment.

When to Choose a CVD Coating

Selecting the right coating technology requires aligning the process capabilities with your specific goal.

- If your primary focus is maximum hardness and wear resistance on a heat-tolerant part: CVD is an excellent choice for its dense, chemically bonded, and highly durable films.

- If you need to coat complex internal geometries or intricate parts uniformly: CVD's gas-phase nature provides unmatched conformal coverage where line-of-sight processes fail.

- If your substrate is temperature-sensitive or cannot be exposed to reactive chemicals: You must look for lower-temperature alternatives like Physical Vapor Deposition (PVD).

Understanding these core principles allows you to select a surface treatment not as a mere layer, but as an integral and engineered part of your component's design.

Summary Table:

| Feature | CVD Coating Characteristic |

|---|---|

| Process | High-temperature chemical reaction in a vacuum chamber |

| Bonding | Chemical bond at the atomic level |

| Uniformity | Exceptional conformality, even on complex geometries |

| Key Advantage | Superior adhesion, hardness, and wear resistance |

| Primary Limitation | Requires high temperatures (800-1000°C), limiting substrate choice |

Need a high-performance coating for your toughest components?

At KINTEK, we specialize in advanced lab equipment and consumables for surface engineering. Our expertise in CVD and other coating technologies can help you achieve unparalleled wear resistance and durability for your tools and parts. Whether you're working with carbides, ceramics, or high-temperature alloys, we have the solutions to meet your laboratory's precise needs.

Contact our experts today to discuss how our CVD solutions can enhance your product's performance and lifespan.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is a key advantage of using Silicon Carbide (SiC) as a substrate for CVD graphene growth? Achieve Free-Standing Graphene

- What is physical Vapour deposition techniques? A Guide to Sputtering, Evaporation & More

- What is CVD with example? A Guide to the Process Behind Lab-Grown Diamonds & Microchips

- How is diamond coating made? A Guide to CVD and PVD Methods

- What is step coverage of physical vapor deposition? Mastering Uniform Thin Films for Microfabrication

- What do you mean by physical vapor deposition and chemical vapor deposition? Choose the Right Thin-Film Process

- What is the primary function of a High Vacuum CVD Furnace? Master High-Quality Graphene Synthesis

- How does a high-precision carbon heating block contribute to the formation of hierarchical structures in an AACVD reactor?