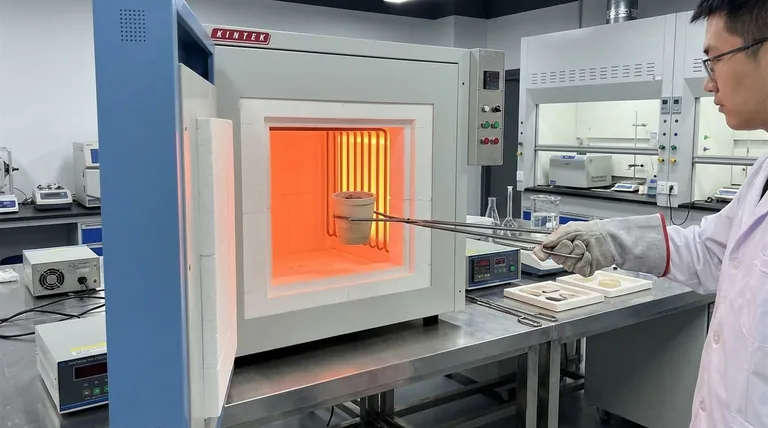

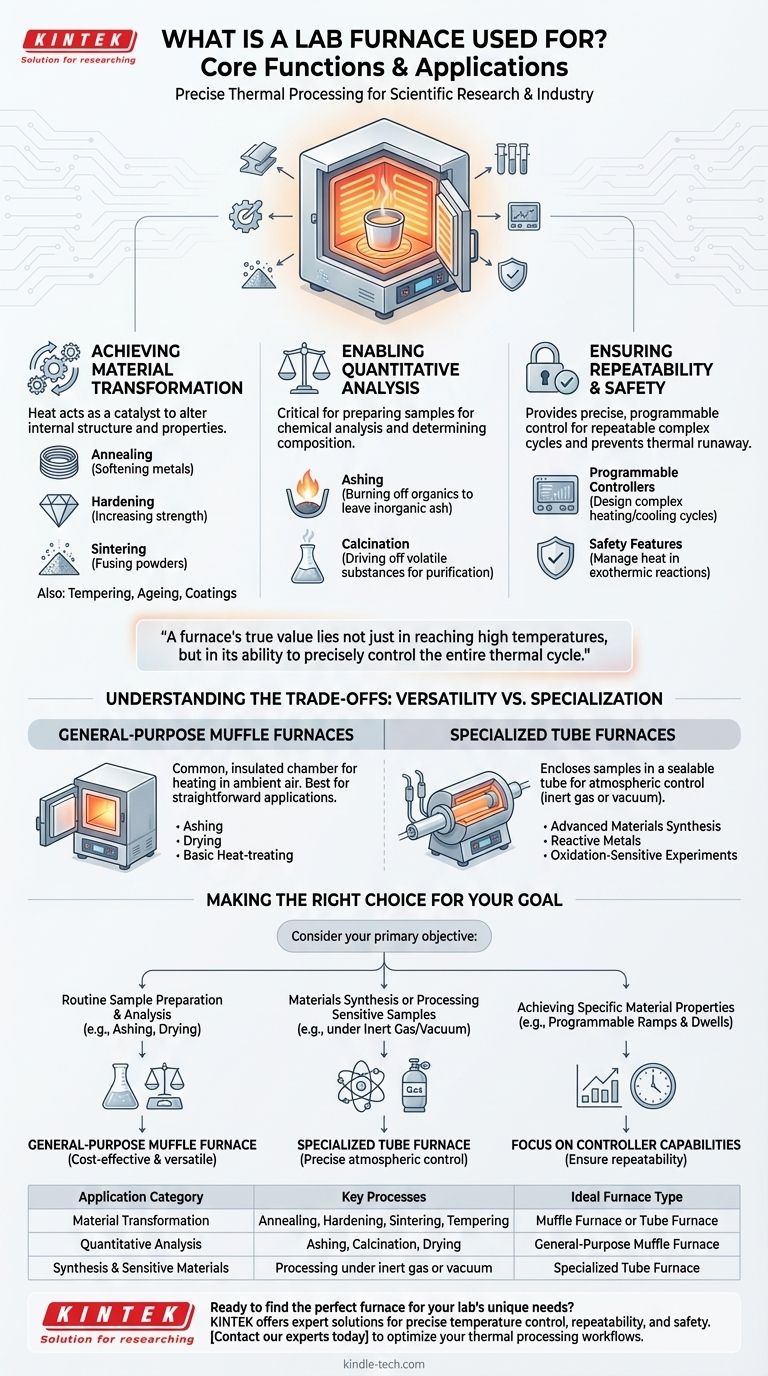

In essence, a laboratory furnace is a high-temperature chamber used to alter the physical and chemical properties of materials in a controlled thermal environment. Its applications are vast and critical for scientific research and industrial quality control, ranging from purifying compounds and preparing samples for analysis to synthesizing entirely new materials.

A furnace's true value lies not just in reaching high temperatures, but in its ability to precisely control the entire thermal cycle. This control is what enables researchers to reliably test, purify, and synthesize materials, making it an indispensable tool for discovery and quality control.

The Core Function: Precise Thermal Processing

A lab furnace applies controlled heat to a sample to achieve a specific, predictable outcome. This fundamental process can be broken down into three main objectives.

Achieving Material Transformation

Heat is a powerful catalyst for changing a material's internal structure and, therefore, its properties.

By precisely managing temperature, ramp rates, and dwell times, a furnace can execute processes like annealing (to soften metals), hardening (to increase strength), and sintering (to fuse powders into a solid mass).

Other common transformations include tempering, ageing, and applying durable coatings.

Enabling Quantitative Analysis

Furnaces are critical tools for preparing samples for chemical analysis. A primary example is determining the composition of a substance.

The process of ashing, for instance, involves heating a sample to burn away all organic matter, leaving only the inorganic ash. By weighing the sample before and after, researchers can accurately determine its non-combustible content.

Similarly, processes like calcination use heat to drive off volatile substances, purifying a material or preparing it for further analysis.

Ensuring Repeatability and Safety

Modern lab furnaces provide a degree of control that is impossible to achieve with a simple bunsen burner or hot plate.

Programmable controllers allow scientists to design and execute complex heating and cooling cycles automatically, ensuring that an experiment can be repeated with exact precision.

This control is also a critical safety feature, helping to prevent dangerous "thermal runaway" in exothermic chemical reactions by managing the rate at which heat is applied or dissipated.

Understanding the Trade-offs: Versatility vs. Specialization

While the term "lab furnace" is broad, the specific type of furnace dictates its capabilities. The choice involves a key trade-off between a general-purpose workhorse and a specialized instrument.

General-Purpose Muffle Furnaces

These are the most common type of lab furnace, featuring an insulated chamber that heats samples in ambient air.

They are excellent for straightforward applications like ashing, drying, and basic heat-treating of materials that are not sensitive to oxygen.

Specialized Tube Furnaces

For materials that would react with air at high temperatures, a tube furnace is required. These enclose the sample in a narrow tube, which can be sealed and filled with an inert gas (like argon) or put under a vacuum.

This atmospheric control is essential for synthesizing advanced materials, processing reactive metals, and conducting experiments where oxidation would compromise the results.

The Importance of Temperature and Control

Beyond the furnace type, the maximum operating temperature and the sophistication of its controller are critical factors.

Some processes require temperatures well over 1500°C, while others depend on the controller's ability to execute very slow temperature ramps or hold a specific temperature with pinpoint accuracy.

Making the Right Choice for Your Goal

Selecting the correct furnace is crucial for achieving accurate and repeatable results. Consider your primary objective to guide your decision.

- If your primary focus is routine sample preparation and analysis: A general-purpose muffle furnace is often the most cost-effective and versatile choice for applications like ashing or simple drying.

- If your primary focus is materials synthesis or processing sensitive samples: You will require a tube furnace that allows for precise atmospheric control (vacuum or inert gas) to prevent unwanted chemical reactions.

- If your primary focus is achieving specific material properties: Pay close attention to the furnace's temperature controller capabilities, including programmable ramp rates and dwell times, to ensure process repeatability.

Ultimately, understanding your specific material and desired outcome is the key to leveraging the transformative power of a laboratory furnace.

Summary Table:

| Application Category | Key Processes | Ideal Furnace Type |

|---|---|---|

| Material Transformation | Annealing, Hardening, Sintering, Tempering | Muffle Furnace or Tube Furnace |

| Quantitative Analysis | Ashing, Calcination, Drying | General-Purpose Muffle Furnace |

| Synthesis & Sensitive Materials | Processing under inert gas or vacuum | Specialized Tube Furnace |

Ready to find the perfect furnace for your lab's unique needs?

Whether your work requires the versatility of a muffle furnace for routine ashing or the precise atmospheric control of a tube furnace for advanced materials synthesis, KINTEK has the solution. Our expertise in lab equipment ensures you get the right tool for precise temperature control, repeatable results, and enhanced safety.

Let's discuss your application. Contact our experts today to optimize your thermal processing workflows.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vertical Laboratory Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the purpose of the molding machine? Your Guide to Efficient Mass Production

- Why is it necessary to configure drying equipment before TSA? Boost CO2 Capture Efficiency and Adsorbent Life

- How does a high-power adjustable speed mixer function in dynamic corrosion testing? Enhance Refractory Simulation

- What are the methods of thin film manufacturing? A Guide to Chemical vs. Physical Deposition

- What does the sputtering yield depend on? Master the Physics for Optimal Thin Film Deposition

- What are the two types of casting machines? Hot-Chamber vs. Cold-Chamber Die Casting

- Why is a powerful magnetic stirrer essential during photocatalytic degradation? Ensure Accurate Catalyst Performance

- What role do precision magnetic stirrers or homogenizers play in the synthesis of Cu-TiO2 sol-gel?