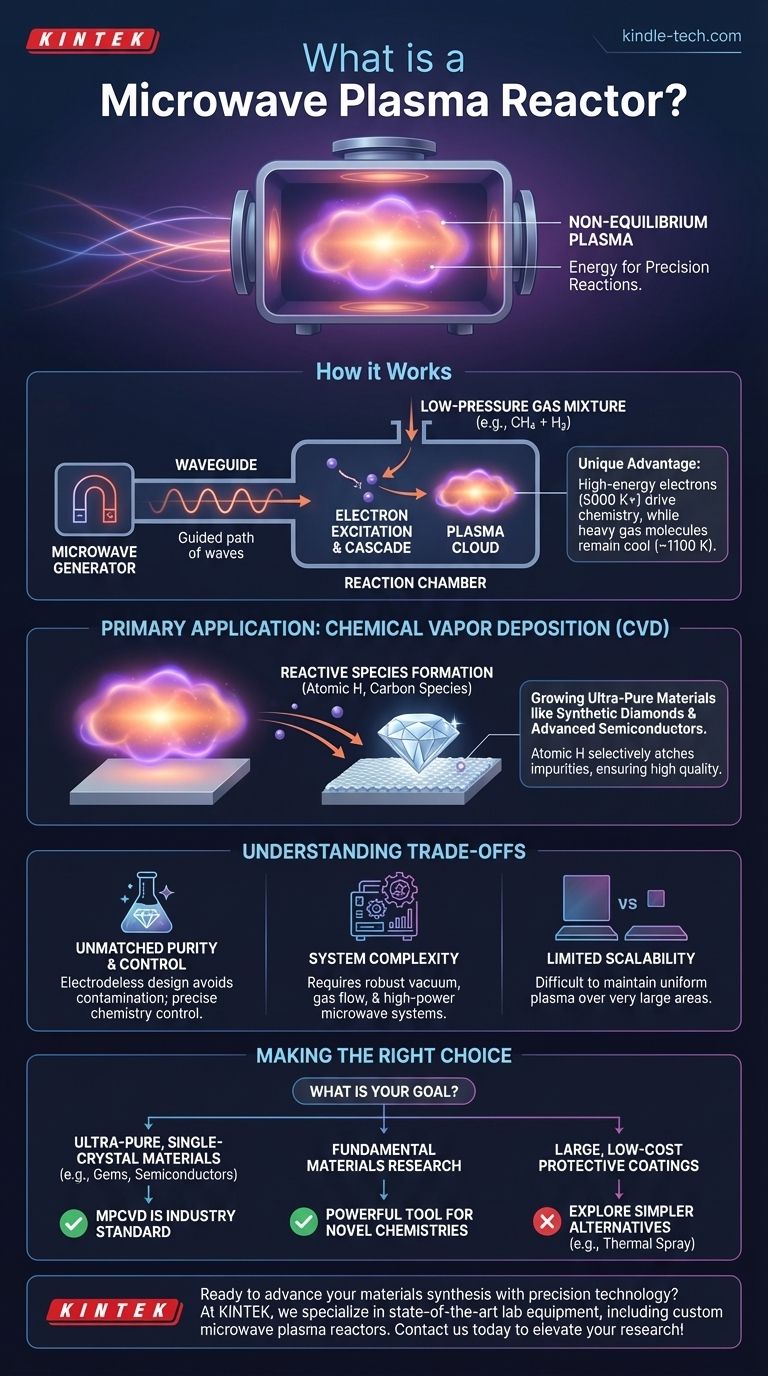

At its core, a microwave plasma reactor is a specialized chamber that uses microwave energy to excite gases into an energized state of matter known as plasma. This plasma is then used to drive chemical reactions that are difficult or impossible to achieve under normal conditions. The most common application is a process called Chemical Vapor Deposition (CVD), where the plasma helps create ultra-pure, high-performance materials like synthetic diamonds or advanced semiconductor films.

The true advantage of a microwave plasma reactor isn't just making plasma—it's creating a unique "non-equilibrium" environment. It generates hyper-energetic electrons to drive specific chemical reactions while keeping the overall gas temperature relatively low, offering unparalleled precision in materials synthesis.

How a Microwave Plasma Reactor Works

To understand the reactor, you must first understand its purpose: to create and sustain a controlled plasma. This is accomplished through a few key components and a distinct physical process.

The Core Components

A typical reactor is not a simple heated vessel. It consists of three essential parts working in concert.

- Microwave Generator: This is the power source, often a magnetron (similar to one in a home microwave, but far more powerful and precise), that produces the high-frequency microwave radiation.

- Waveguide: This is a set of metal tubes that carefully guides the microwaves from the generator into the reaction chamber, focusing the energy where it is needed.

- Reaction Chamber: This is a sealed, vacuum-tight chamber where the process occurs. It's filled with low-pressure gas and contains the substrate—the surface where the new material will be grown.

The Process of Plasma Generation

The process begins by pumping the air out of the reaction chamber and introducing a specific mixture of gases, such as methane (CH4) and hydrogen (H2) for diamond growth, at very low pressure.

Microwaves are then channeled into the chamber. The rapidly oscillating electric field of the microwaves energizes the few free electrons naturally present in the gas. These electrons accelerate to tremendous speeds and collide with neutral gas atoms, knocking off more electrons and creating a cascade of ionization.

This self-sustaining chain reaction results in a glowing cloud of electrons, ions, and highly reactive neutral fragments, which is the plasma.

The Unique Nature of Microwave Plasma

The defining characteristic of this technology is the creation of a non-equilibrium plasma.

The lightweight electrons absorb the microwave energy very efficiently, reaching extreme temperatures—often over 5,000 K. However, the much heavier gas molecules and ions do not heat up as quickly, remaining at a significantly lower temperature, perhaps around 1,100 K.

This massive temperature difference means you can have the chemical reactivity of an extremely hot environment without needing to heat the entire chamber and substrate to destructive levels.

Primary Application: Chemical Vapor Deposition (CVD)

The most prominent use for these reactors is Microwave Plasma Chemical Vapor Deposition (MPCVD), a technique for growing high-quality solid materials.

Creating the Chemical Building Blocks

The hyper-energetic electrons in the plasma are perfect for breaking apart stable gas molecules.

For example, in diamond synthesis, the plasma efficiently splits stable methane (CH4) and hydrogen (H2) molecules into reactive carbon species and atomic hydrogen (H). These are the fundamental building blocks for diamond.

Enabling High-Purity Growth

These reactive species then travel to the surface of a substrate (like a small diamond seed crystal). The carbon species stick to the surface and arrange themselves into the diamond crystal lattice.

Crucially, the atomic hydrogen plays a secondary role: it preferentially etches away any carbon that doesn't form a perfect diamond bond. This selective removal process is why MPCVD is renowned for producing diamonds of exceptionally high purity and quality.

Understanding the Trade-offs

While powerful, microwave plasma technology is not a universal solution. It involves specific advantages and challenges that dictate its use.

The Advantage: Unmatched Purity and Control

Because the plasma is generated by microwaves, there are no electrodes inside the chamber that could erode and contaminate the material being grown. This "electrodeless" nature, combined with the precise control over gas chemistry and energy, allows for the synthesis of ultra-pure materials.

The Challenge: System Complexity

MPCVD systems are sophisticated machines. They require robust vacuum systems, precise gas flow controllers, and stable high-power microwave electronics. Operating them effectively requires significant technical expertise.

The Limitation: Scalability

Achieving a perfectly uniform plasma over a very large area is a significant engineering challenge. This can limit the size of the substrate that can be coated uniformly, making it more suited for high-value, smaller-area applications than for bulk industrial coating of large surfaces.

Making the Right Choice for Your Goal

Deciding whether this technology fits your needs depends entirely on your final objective.

- If your primary focus is synthesizing ultra-pure, single-crystal materials like gem-quality diamonds or advanced semiconductors: The cleanliness and precise control of MPCVD are unparalleled and represent the industry standard.

- If your primary focus is fundamental materials research: The unique non-equilibrium plasma environment provides a powerful tool for exploring novel chemistries and growing exotic materials that cannot be made otherwise.

- If your primary focus is applying a simple, low-cost protective coating to a large object: You may find the complexity and scalability challenges of MPCVD prohibitive and should explore simpler alternatives like thermal spraying or atmospheric plasma.

Ultimately, mastering this technology comes from understanding its core principle: using targeted energy to create a unique reactive state for precision engineering at the atomic scale.

Summary Table:

| Feature | Description |

|---|---|

| Core Function | Uses microwave energy to create a non-equilibrium plasma for driving chemical reactions. |

| Primary Application | Chemical Vapor Deposition (CVD), especially for synthesizing high-purity materials like diamonds. |

| Key Advantage | Electrode-less design ensures ultra-pure synthesis; precise control over reactions. |

| Main Challenge | System complexity and limited scalability for large-area coatings. |

| Ideal For | Research and production of high-value, high-purity materials (e.g., semiconductors, synthetic diamonds). |

Ready to advance your materials synthesis with precision technology?

At KINTEK, we specialize in providing state-of-the-art lab equipment, including microwave plasma reactors tailored for Chemical Vapor Deposition (CVD) and other advanced applications. Whether you're growing ultra-pure diamonds, developing next-generation semiconductors, or pushing the boundaries of materials research, our solutions deliver the unmatched purity and control you need.

Let our experts help you harness the power of non-equilibrium plasma for your laboratory. Contact us today to discuss your specific requirements and discover how KINTEK can elevate your research and production capabilities!

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How long does it take to make lab grown diamonds? From Weeks to Months for Perfection

- What pressure is needed for chemical vapor deposition of diamonds? Master the Low-Pressure 'Sweet Spot'

- What are the applications of nano crystalline diamond films? Unlock Extreme Performance for Your Tech

- Can a jeweler distinguish a lab grown diamond? The Truth About Identifying Diamond Origin

- Do natural diamonds last longer? The Truth About Diamond Durability and Value

- What are diamond films used for? Enhancing Tools, Electronics, and Implants with Diamond Surfaces

- How does Microwave Plasma Chemical Vapour Deposition (MPCVD) work? Your Guide to High-Purity Diamond Film Growth

- Are lab-grown diamonds comparable to natural diamonds? Discover the Science Behind the Sparkle