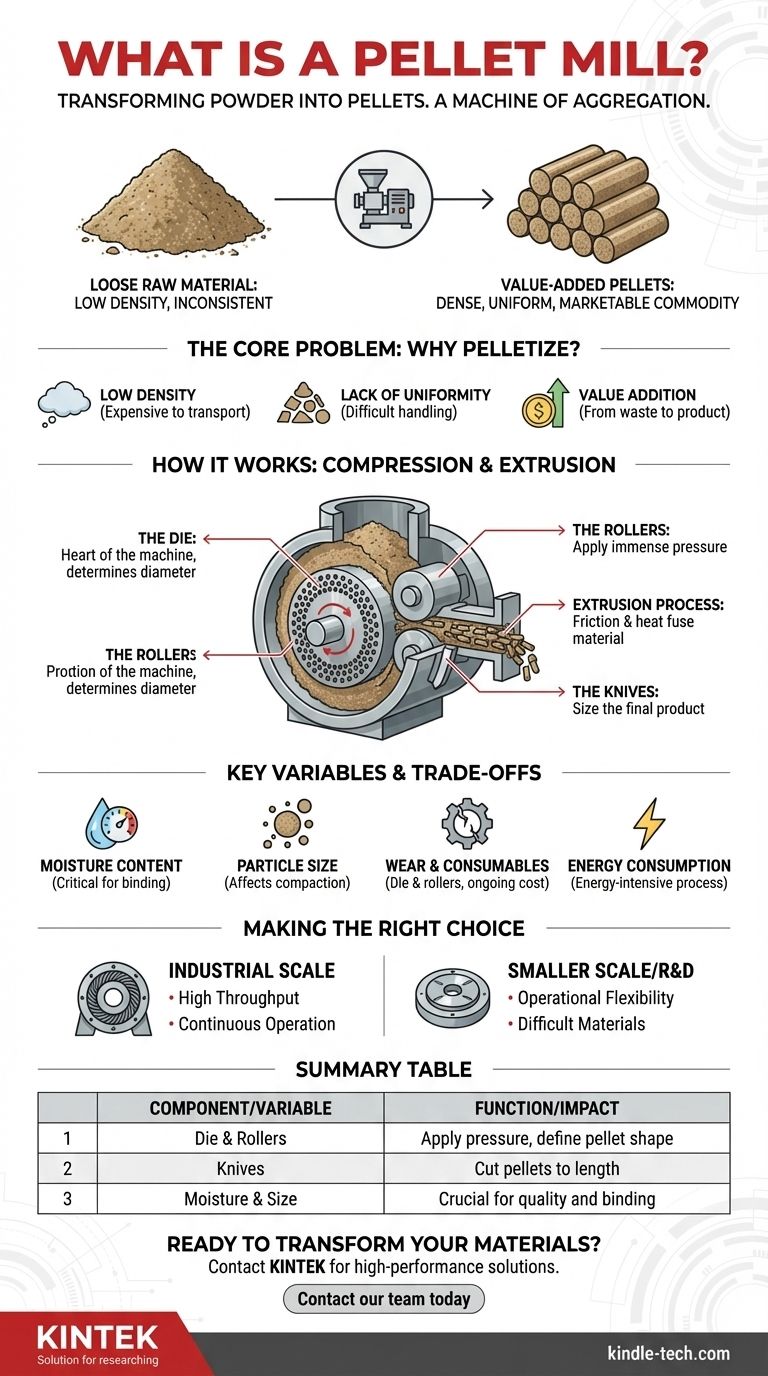

In short, a pellet mill is a machine that transforms powder into pellets. Unlike a grinding mill that breaks large materials down, a pellet press is a machine of aggregation. It takes loose, low-density raw material and uses immense pressure and friction to compact it into a dense, uniform, and more valuable final product.

The core function of a pellet mill is to solve the logistical and economic problems of handling bulk materials. By increasing density and creating uniformity, it makes materials like biomass or animal feed vastly easier to store, transport, and use efficiently.

The Core Problem: Why Pelletize Material?

Before understanding how a pellet mill works, it's crucial to understand the problem it solves. Raw materials like sawdust, agricultural residue, or feed ingredients present significant challenges in their natural state.

The Challenge of Low Density

Loose biomass or powdered material is mostly air. This low bulk density makes it incredibly expensive and inefficient to transport and store, requiring massive volumes for relatively little mass.

The Need for Uniformity

Raw materials are inconsistent in size, shape, and moisture. This lack of uniformity makes them difficult to handle in automated systems, and it leads to inconsistent outcomes, whether in a furnace for energy or as feed for livestock.

The Goal of Value Addition

By converting a difficult-to-handle byproduct or raw material into a standardized, flowable pellet, the process unlocks significant economic value. It creates a marketable commodity from what might otherwise be considered waste.

How a Pellet Mill Achieves Compression

The transformation from powder to pellet happens through a process of intense mechanical pressure and friction within the mill's core components.

The Die: The Heart of the Machine

The central component is the die, a thick, hardened steel plate or ring perforated with hundreds of precisely drilled holes. The diameter of these holes determines the final diameter of the pellet.

The Rollers: The Source of Pressure

Inside the mill, one or more rollers rotate against the inner surface of the die. As raw material is fed into the chamber, it gets caught between the rollers and the die.

The Extrusion Process

The immense pressure generated by the rollers forces the material through the holes in the die. This compression generates significant heat from friction, which helps to soften natural binders within the material (like lignin in wood), allowing it to fuse into a solid mass.

The Knives: Sizing the Final Product

As the dense, compacted material is extruded out the other side of the die, a set of adjustable knives cuts it to a predetermined length, creating the final, uniform pellets.

Understanding the Trade-offs and Key Variables

While the concept is straightforward, successful pellet production is a precise science with critical operational considerations.

Material Preparation is Paramount

A pellet mill is not a magic box. The incoming raw material must be prepared to strict specifications. Moisture content and particle size are the two most critical variables; failure to control them results in poor-quality pellets or can even damage the machine.

Wear is an Inevitable Cost

The process of forcing abrasive material through steel holes under extreme pressure is highly aggressive. The die and rollers are consumable parts that will wear out over time and represent a significant ongoing operational expense.

Energy Consumption

Generating the required pressure is an energy-intensive process. The energy cost per ton of production is a key factor in the economic viability of any pelleting operation.

Making the Right Choice for Your Goal

The type of mill and operational focus depend entirely on your intended application and scale.

- If your primary focus is large-scale industrial production (e.g., fuel pellets, commercial animal feed): You will require an industrial ring die pellet mill, which is designed for high throughput and continuous operation.

- If your primary focus is smaller-scale or specialty production (e.g., R&D, pilot plants, high-fiber materials): A flat die pellet mill can offer more operational flexibility and may perform better with difficult-to-pelletize materials.

- If your primary focus is maximizing efficiency and quality: Your attention must be on the pre-processing system—drying and grinding—as the quality of the material entering the mill dictates the quality of the pellets coming out.

Ultimately, a pellet mill is a powerful tool of transformation, engineered to convert a low-value bulk substance into a high-value, standardized commodity.

Summary Table:

| Key Component | Function |

|---|---|

| Die | A hardened steel plate with holes that determines the pellet's diameter. |

| Rollers | Apply immense pressure to force material through the die holes. |

| Knives | Cut the extruded material into uniform pellet lengths. |

| Critical Variables | Impact on Production |

| Material Moisture | Must be controlled precisely for proper binding and pellet quality. |

| Particle Size | Affects how well the material compacts and flows through the die. |

Ready to transform your raw materials into a valuable, marketable product?

Whether you're scaling up industrial production or optimizing a pilot plant, the right equipment is critical to your success. KINTEK specializes in high-performance lab equipment and consumables, including robust pellet mills designed for reliability and efficiency.

We understand that successful pelleting depends on more than just the machine—it's about the entire process, from material preparation to final product quality. Our experts can help you select the ideal solution for your specific material and production goals.

Contact our team today to discuss how KINTEK's solutions can enhance your pelleting operation and add significant value to your materials.

Visual Guide

Related Products

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- kbr pellet press 2t

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why is a hydraulic press used for vacuum carbothermic magnesium reduction pellets? Protect Systems & Enhance Gas Flow

- What is the ratio of KBr and sample in IR? Achieve Perfect Sample Concentration for Clear IR Spectra

- Why is a laboratory hydraulic press essential for Ca3Co4O9 pelletizing? Optimize Pre-Sintering Mass Transport

- Why is KBr used as a mulling agent in IR? Achieve Clear, Accurate Solid Sample Analysis