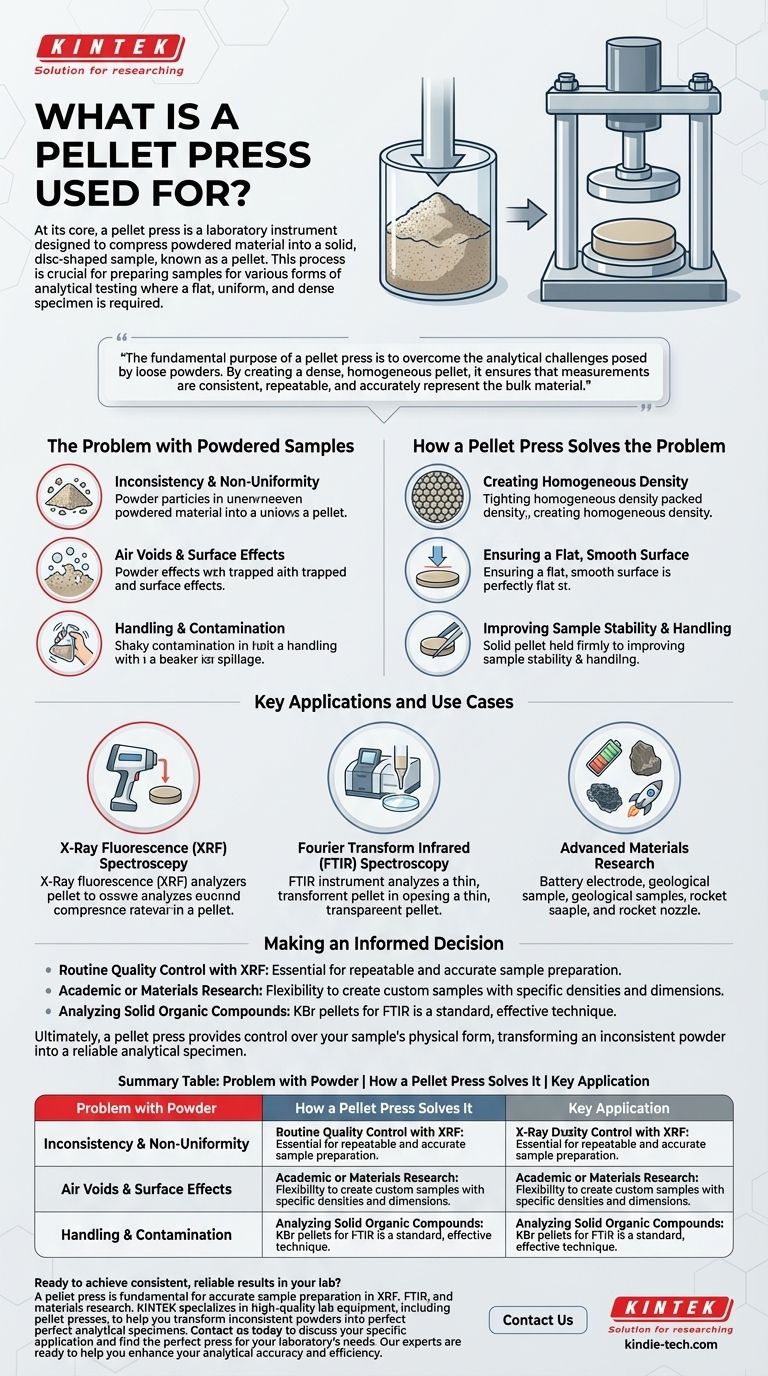

At its core, a pellet press is a laboratory instrument designed to compress powdered material into a solid, disc-shaped sample, known as a pellet. This process is crucial for preparing samples for various forms of analytical testing where a flat, uniform, and dense specimen is required. The press uses a die set and significant hydraulic force to transform loose powder into a cohesive, solid form suitable for analysis.

The fundamental purpose of a pellet press is to overcome the analytical challenges posed by loose powders. By creating a dense, homogeneous pellet, it ensures that measurements are consistent, repeatable, and accurately represent the bulk material.

The Problem with Powdered Samples

Inconsistency and Non-Uniformity

Loose powders have inconsistent density and an uneven surface. This variability makes it difficult to get a reliable reading with many analytical techniques, as the results can change depending on how the powder is packed.

Air Voids and Surface Effects

Air trapped between powder grains can interfere with measurements. Techniques that rely on surface interaction, like X-Ray Fluorescence (XRF), are particularly sensitive to these imperfections, leading to inaccurate results.

Handling and Contamination

Powdered samples are difficult to handle, transfer, and mount without loss or contamination. This creates practical challenges in a laboratory setting and can compromise the integrity of the analysis.

How a Pellet Press Solves the Problem

Creating Homogeneous Density

A pellet press applies immense, evenly distributed pressure (often measured in tons) to the powder within a hardened steel die. This force compacts the particles, eliminates air voids, and creates a solid sample with a uniform density throughout.

Ensuring a Flat, Smooth Surface

The polished surfaces of the die set impart a smooth, perfectly flat finish to the pellet. This ideal surface is essential for analytical methods that measure surface properties, as it minimizes scattering and ensures a consistent focal point for instrument beams.

Improving Sample Stability and Handling

Once pressed, the solid pellet is robust and easy to handle with tweezers. It can be stored, labeled, and placed into analytical instruments without the risk of spillage or changes to its composition, ensuring a stable and repeatable analytical process.

Key Applications and Use Cases

X-Ray Fluorescence (XRF) Spectroscopy

This is one of the most common applications. Pressing a powder into a pellet is a standard sample preparation method for XRF, as it provides the ideal dense, homogeneous sample required for accurate elemental analysis.

Fourier Transform Infrared (FTIR) Spectroscopy

For FTIR analysis of solid samples, a small amount of the powdered material is often mixed with potassium bromide (KBr) powder. This mixture is then pressed into a thin, transparent pellet, allowing the infrared beam to pass through for analysis.

Advanced Materials Research

Researchers use pellet presses to create samples for a wide range of studies. This includes fabricating geological samples for testing, forming battery electrodes, creating sputtering targets for thin-film deposition, and even developing specialized materials for applications like rocket nozzles.

Making an Informed Decision

- If your primary focus is routine quality control with XRF: A pellet press is an essential tool for ensuring your sample preparation is repeatable and accurate.

- If your primary focus is academic or materials research: The press provides the flexibility to create custom samples with specific densities and dimensions for experimental testing.

- If your primary focus is analyzing solid organic compounds: Using a press to create KBr pellets for FTIR spectroscopy is a standard, highly effective technique.

Ultimately, a pellet press provides control over your sample's physical form, transforming an inconsistent powder into a reliable analytical specimen.

Summary Table:

| Problem with Powder | How a Pellet Press Solves It | Key Application |

|---|---|---|

| Inconsistent Density & Non-Uniformity | Creates a homogeneous, solid sample | X-Ray Fluorescence (XRF) |

| Air Voids & Surface Imperfections | Eliminates voids for a flat, smooth surface | FTIR Spectroscopy (KBr Pellets) |

| Difficult Handling & Contamination | Produces a robust, easy-to-handle pellet | Advanced Materials Research |

Ready to achieve consistent, reliable results in your lab?

A pellet press is fundamental for accurate sample preparation in XRF, FTIR, and materials research. KINTEK specializes in high-quality lab equipment, including pellet presses, to help you transform inconsistent powders into perfect analytical specimens.

Contact us today to discuss your specific application and find the perfect press for your laboratory's needs. Our experts are ready to help you enhance your analytical accuracy and efficiency.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

People Also Ask

- What are the risks of a hydraulic press? Essential Safety and Operational Insights

- How do you make biomass pellets at home? A Step-by-Step Guide to DIY Fuel Production

- How do you prepare samples for infrared spectroscopy? Master Solid, Liquid & Gas Techniques

- Can a hydraulic press shatter a diamond? Yes, and here's why hardness isn't toughness.

- How many tons can a hydraulic press produce? From 1 to 50,000+ Tons Explained

- What is the mechanical press forging process? High-Speed Precision for Mass Production

- How do you prepare a sample for fluorescence spectroscopy? A Step-by-Step Guide for Accurate Results

- What function does a laboratory hydraulic press perform for sulfide electrolytes? Achieve 90%+ Densification Today