At its core, a planetary ball mill is a high-energy grinding tool used to reduce a wide variety of materials into extremely fine powders. This size-reduction process, known as comminution, works on hard, soft, brittle, and even moist samples. The machine achieves this through the intense impact and friction forces generated by grinding balls moving inside rotating jars.

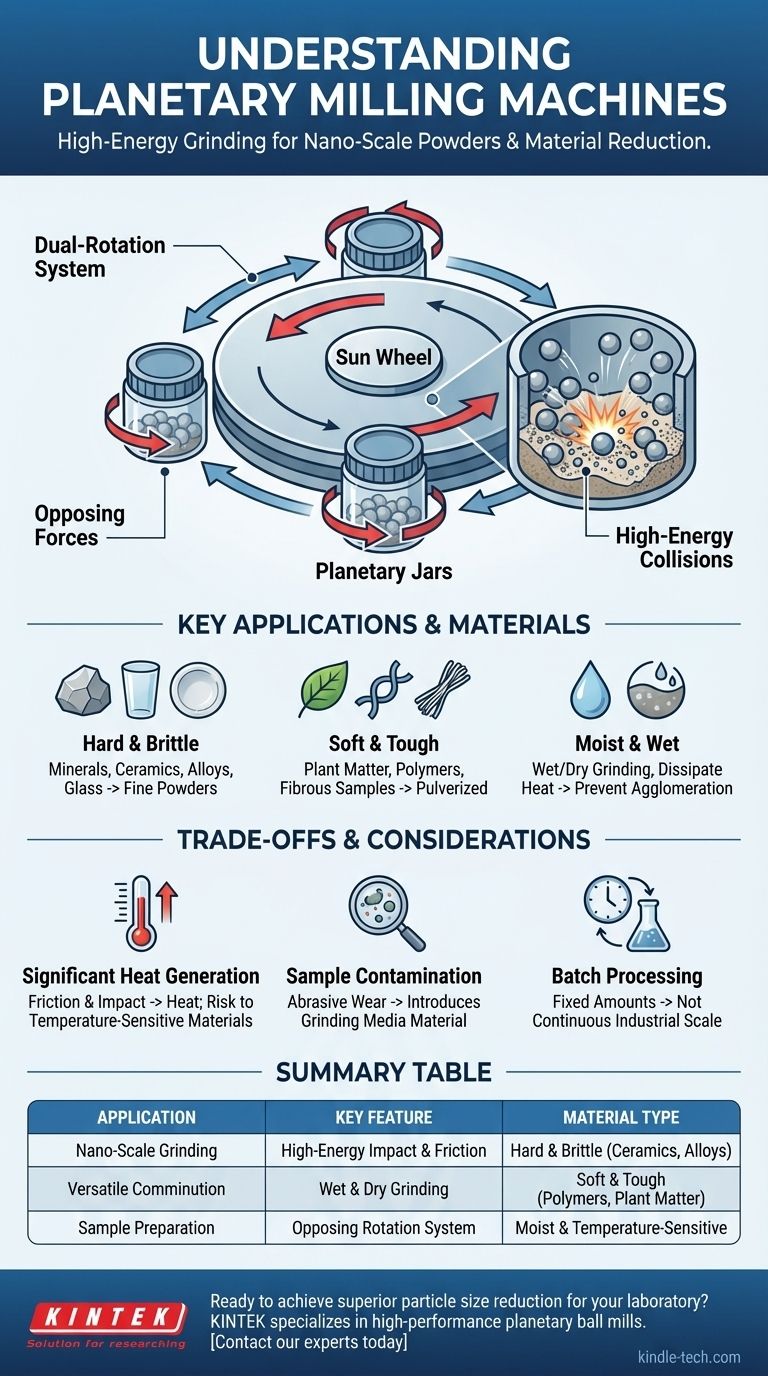

A planetary mill's effectiveness comes from its unique dual-rotation system. Grinding jars, mounted on a larger rotating disk, spin in the opposite direction of the disk itself. This opposing motion creates exceptionally high-energy collisions, making it a superior choice for producing nano-scale particles.

The Mechanics of High-Energy Grinding

To understand what a planetary mill is used for, you must first understand how its forces are generated. The design is elegant but creates a powerful, and sometimes violent, grinding environment.

The "Planetary" System

The machine gets its name from its resemblance to a planetary system. A large primary disk, the "sun wheel," rotates in one direction.

Mounted on this sun wheel are smaller grinding jars, the "planets." These jars contain the material to be ground along with the grinding media (typically balls).

Opposing Rotational Forces

The critical feature is that the grinding jars rotate on their own axes in the opposite direction of the sun wheel.

This counter-rotation causes the grinding balls inside the jars to separate from and repeatedly crash against the inner wall of the jar with tremendous force.

The Role of Grinding Media

The comminution, or particle size reduction, happens primarily through this high-energy impact.

The grinding balls pulverize the sample material trapped between them and the jar wall. This process generates not only impact but also significant friction, further breaking down the particles.

Key Applications and Material Types

The high forces generated by a planetary mill make it exceptionally versatile, capable of handling materials that are difficult to process with other methods.

Grinding Hard and Brittle Materials

This is a primary application. Planetary mills excel at pulverizing hard minerals, ceramics, alloys, and glass down to very fine powders.

Processing Soft and Tough Materials

The combination of impact and friction is also effective for softer materials. This includes plant matter, polymers, and other fibrous or tough samples that might resist other grinding methods.

Handling Moist Samples

Planetary mills can be used for both wet and dry grinding. Wet grinding with a suitable solvent can help dissipate heat, prevent particle agglomeration, and achieve even finer results.

Understanding the Trade-offs and Considerations

While powerful, a planetary mill is not the right tool for every situation. Its high-energy nature introduces specific challenges that must be managed.

Significant Heat Generation

The immense friction and impact generate considerable heat within the grinding jars. This can be detrimental to temperature-sensitive materials, potentially altering their chemical or physical structure.

Potential Sample Contamination

The grinding process is abrasive by nature. Over time, the grinding balls and the inner walls of the jars will wear, introducing microscopic amounts of their own material into your sample. For high-purity applications, this is a critical factor.

Batch Processing Limitations

Most laboratory-scale planetary mills are batch-processing instruments. This means they can only process a fixed amount of material at a time, which may not be suitable for large-scale, continuous industrial production.

Making the Right Choice for Your Goal

Selecting a planetary mill depends entirely on your end goal and the nature of your sample material.

- If your primary focus is achieving the smallest possible particle size (nanoscale): A planetary mill is one of the most effective tools available due to its unmatched high-energy grinding principle.

- If your primary focus is processing temperature-sensitive materials: You must account for the significant heat generation, which may require you to run shorter cycles, use cooling systems, or perform wet grinding.

- If your primary focus is maintaining absolute sample purity: Carefully select the material of your grinding jars and balls (e.g., agate, zirconia) to minimize contamination from abrasion.

Ultimately, a planetary mill is a powerful and versatile instrument when its operational principles are correctly matched to the material and the desired outcome.

Summary Table:

| Application | Key Feature | Material Type |

|---|---|---|

| Nano-Scale Grinding | High-Energy Impact & Friction | Hard & Brittle Materials (Ceramics, Alloys) |

| Versatile Comminution | Wet & Dry Grinding Capability | Soft & Tough Materials (Polymers, Plant Matter) |

| Sample Preparation | Opposing Rotation System | Moist & Temperature-Sensitive Samples |

Ready to achieve superior particle size reduction for your laboratory? KINTEK specializes in high-performance planetary ball mills and lab equipment, offering precise solutions for grinding hard, soft, and brittle materials into nano-scale powders. Contact our experts today to find the perfect milling solution for your specific application and material needs!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary purpose of using WC milling jars and balls? Achieve Ultra-Pure W-TiC Composite Alloying

- What is the purpose of the wet ball milling process? Optimize Li8/7Ti2/7V4/7O2 Cathode Synthesis Quality

- Why are stainless steel jars and quenched steel balls preferred for Fe3Si? Optimize Purity and Efficiency

- What is the primary function of a high-energy planetary ball mill? Powering Sulfide Solid-State Electrolyte Synthesis

- How does a high-energy ball mill enhance the catalytic activity of biomass carbon materials? Boost Surface Reactivity

- What is the primary function of ball milling in the preparation of Al2O3/ZrO2 gradient ceramic tool materials? Key Mixing

- What is the function of a high-energy ball mill in the post-treatment of calcium-based adsorbents? Enhance CO2 Capture

- What is the primary function of a high-speed ball mill? Master UHMWPE/Nano-HAP Dispersion