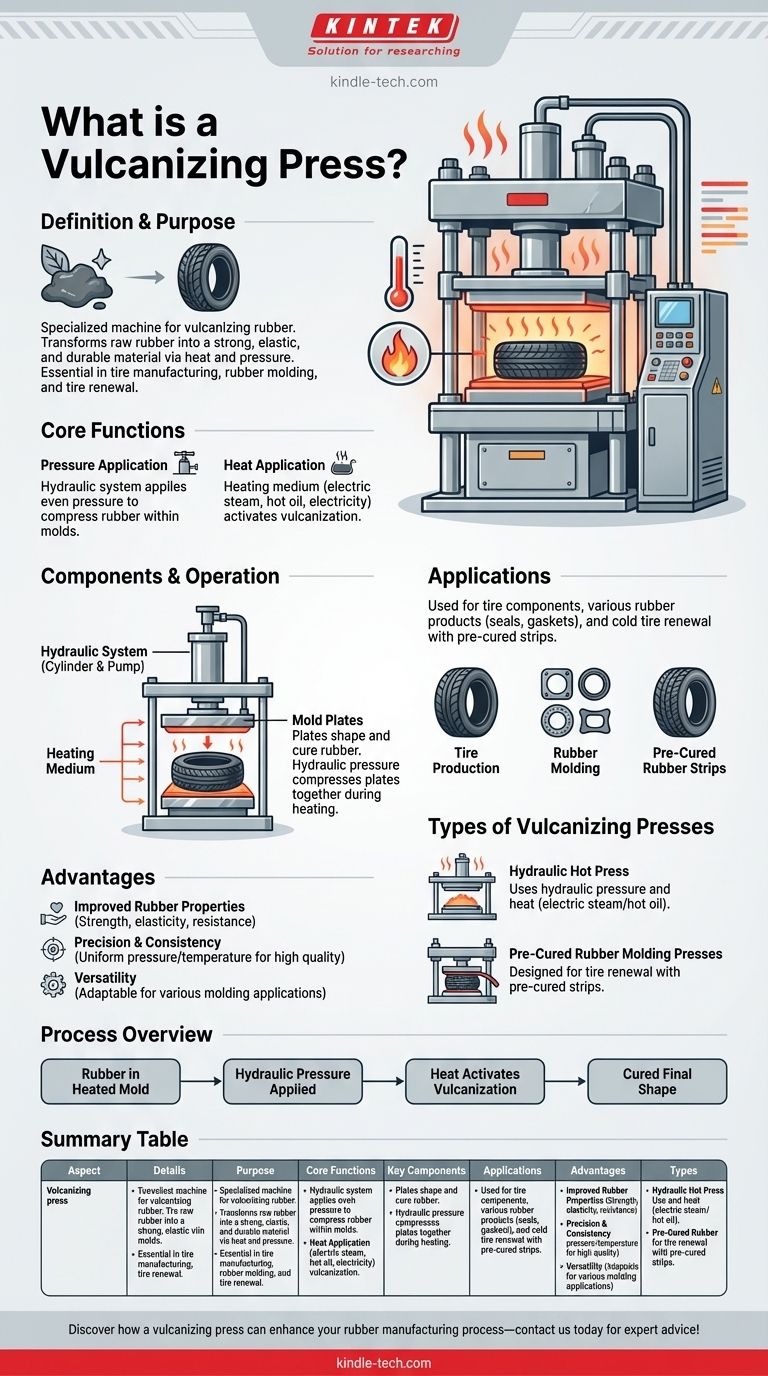

A vulcanizing press is a specialized machine used in the rubber manufacturing industry to vulcanize rubber compounds. Vulcanization is a chemical process that involves heating rubber under pressure to improve its strength, elasticity, and durability. The press provides the necessary pressure and temperature for this process, typically using a hydraulic system to generate pressure and a heating medium (such as electric steam or hot oil) to supply heat. The rubber compound is placed between heated mold plates, which are pressed together to shape and cure the rubber into the desired form. Vulcanizing presses are widely used in applications such as tire production, rubber molding, and the renewal of pre-cured rubber strips for tires.

Key Points Explained:

-

Definition and Purpose of a Vulcanizing Press:

- A vulcanizing press is a machine designed to vulcanize rubber, a process that transforms raw rubber into a more durable and elastic material.

- It is essential in industries like tire manufacturing, rubber molding, and tire renewal processes.

-

Core Functions:

- Pressure Application: The press uses a hydraulic system to apply pressure, ensuring the rubber compound is evenly compressed within the mold.

- Heat Application: A heating medium (electric steam, hot oil, or electricity) provides the necessary temperature to activate the vulcanization process.

-

Components and Operation:

- Hydraulic System: Generates the pressure required to compress the rubber compound. This system typically includes a hydraulic cylinder and pump.

- Heating Medium: Supplies heat to the mold plates, which transfer the heat to the rubber compound.

- Mold Plates: These are metal plates with cavities that shape the rubber into the desired finished product. The plates are pressed together hydraulically during the vulcanization process.

-

Applications:

- Tire Production: Vulcanizing presses are used to mold and cure rubber into tire components, ensuring durability and performance.

- Pre-Cured Rubber Strips: These presses are also used in the cold renewal process of tires, where pre-cured rubber strips are bonded to worn tire treads.

- Rubber Molding: The presses are employed to create various rubber products, such as seals, gaskets, and industrial components.

-

Advantages of Vulcanizing Presses:

- Improved Rubber Properties: Vulcanization enhances the rubber's strength, elasticity, and resistance to wear and tear.

- Precision and Consistency: The press ensures uniform pressure and temperature, resulting in high-quality, consistent products.

- Versatility: These machines can be adapted for various rubber molding and curing applications.

-

Types of Vulcanizing Presses:

- Hydraulic Hot Press: Uses hydraulic pressure and heat (via electric steam or hot oil) to vulcanize rubber.

- Pre-Cured Rubber Molding Presses: Specifically designed for tire renewal processes, allowing for the application of pre-cured rubber strips to worn tires.

-

Process Overview:

- The rubber compound is placed between the heated mold plates.

- The hydraulic system applies pressure, compressing the rubber into the mold cavities.

- Heat from the plates activates the vulcanization process, curing the rubber into its final shape.

By combining pressure and heat, a vulcanizing press ensures the efficient and effective transformation of raw rubber into durable, high-performance products. Its versatility and precision make it an indispensable tool in the rubber manufacturing industry.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Vulcanizes rubber to enhance strength, elasticity, and durability. |

| Core Functions | Applies pressure (hydraulic system) and heat (electric steam, hot oil). |

| Key Components | Hydraulic system, heating medium, mold plates. |

| Applications | Tire production, rubber molding, pre-cured rubber strip renewal. |

| Advantages | Improves rubber properties, ensures precision, and offers versatility. |

| Types | Hydraulic hot press, pre-cured rubber molding press. |

Discover how a vulcanizing press can enhance your rubber manufacturing process—contact us today for expert advice!

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Double Plate Heating Press Mold for Lab

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the use of two roll mill? Essential for Polymer Mixing, R&D, and Quality Control

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability

- What is the main purpose of vulcanization? Transform Rubber into a Durable, Elastic Material

- What is a calendering machine? Transform Material Surfaces with Precision

- What is the importance of injection moulding machine? Unlocking High-Volume, Precision Manufacturing

- What are the three 3 basic types of mixers? Find Your Perfect Match for Baking & Production

- What is the working principle of rolling mill? It Depends on Your Material Processing Goal

- What is the principle of mixing on open two roll mill? Master Shear, Compression & Heat for Uniform Blending