At its core, a wood pellet mill is a machine that transforms low-density biomass waste into highly-concentrated, uniform fuel pellets. It is not a grinder that breaks things down, but a press that combines and compresses fine materials, like sawdust or agricultural residue, into a larger, homogenous mass through intense pressure.

The fundamental purpose of a pellet mill is to dramatically increase the energy density and uniformity of raw biomass. It achieves this by using immense pressure and friction to activate the natural binders within the wood itself, creating a stable, easy-to-handle biofuel.

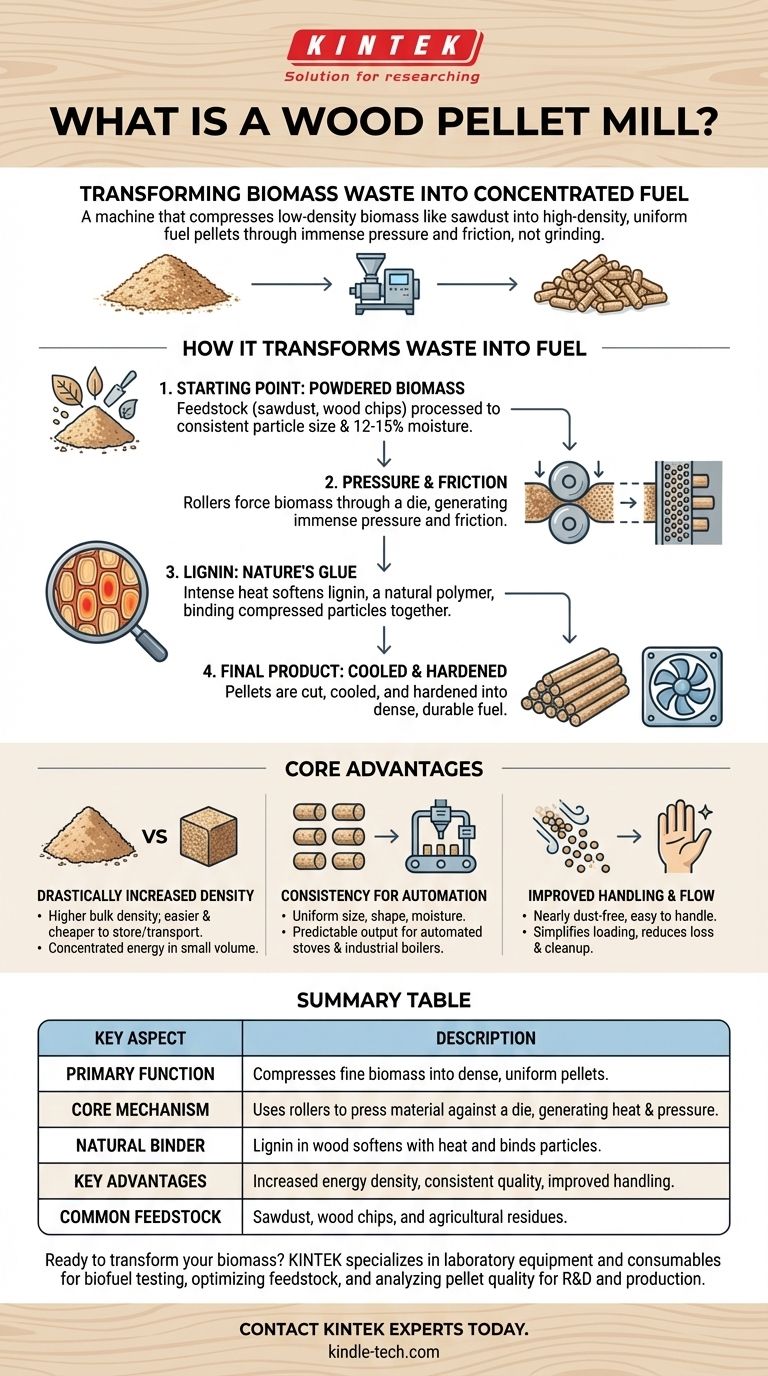

How a Pellet Mill Transforms Waste into Fuel

Understanding a pellet mill requires looking beyond its simple function of compression. The process is a careful balance of material preparation, pressure, and heat that fundamentally changes the nature of the raw material.

The Starting Point: Powdered Biomass

The process begins with a feedstock, typically wood waste like sawdust, wood chips, or even agricultural byproducts. This raw material must be processed to a consistent, fine particle size and have a specific moisture content, usually between 12-15%, for the process to work effectively.

The Power of Pressure and Friction

Inside the mill, rollers continuously press the prepared biomass against a perforated metal plate known as a die. This action forces the material through the small holes in the die, creating immense pressure and friction.

Lignin: Nature's Glue

The intense friction generates significant heat. This heat softens the lignin, a natural polymer found in wood's cell walls. The softened lignin acts as a natural glue, binding the compressed wood particles together as they are extruded through the die.

The Final Product: Cooled and Hardened Pellets

As the compressed material exits the die, a cutter slices it into uniform lengths, creating the familiar pellet shape. These newly formed pellets are extremely hot and soft. They are then cooled, which causes the lignin to harden, resulting in a dense, durable, and stable fuel pellet.

Understanding the Core Advantages

The reason for converting loose biomass into pellets comes down to three critical advantages that solve the inherent problems of using raw wood waste as fuel.

Drastically Increased Density

Pellets have a much higher bulk density than their source material. This makes them significantly easier and more cost-effective to store and transport, concentrating a large amount of energy potential into a small, manageable volume.

Consistency for Automated Systems

Because every pellet is nearly identical in size, shape, and moisture content, they provide a predictable and consistent energy output. This uniformity is essential for the reliable and efficient operation of automated pellet stoves and industrial boilers.

Improved Handling and Flow

Unlike sawdust or wood chips, which can be messy and difficult to handle, pellets flow easily and are nearly dust-free. This simplifies loading into hoppers and reduces material loss and cleanup.

Making the Right Choice for Your Goal

Whether a pellet mill is a viable solution depends entirely on your access to raw materials and your ultimate objective.

- If your primary focus is managing agricultural or forestry waste: A pellet mill is an excellent technology for converting a low-value byproduct into a marketable, high-density energy product.

- If your primary focus is producing fuel for personal use: A smaller, flat die mill can provide energy independence, but it requires a consistent and properly prepared supply of raw material to be practical.

- If your primary focus is large-scale commercial fuel production: An industrial ring die mill is necessary, representing a significant capital investment that must be supported by a robust and reliable biomass supply chain.

Ultimately, a pellet mill is a powerful tool for unlocking the stored energy in materials that would otherwise be considered waste.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Function | Compresses fine biomass into dense, uniform pellets. |

| Core Mechanism | Uses rollers to press material against a die, generating heat and pressure. |

| Natural Binder | Lignin in the wood softens with heat and binds the particles. |

| Key Advantages | Increased energy density, consistent fuel quality, and improved handling. |

| Common Feedstock | Sawdust, wood chips, and agricultural residues. |

Ready to transform your biomass into a valuable energy source?

KINTEK specializes in robust laboratory equipment and consumables for testing and developing biofuel processes. Whether you're in R&D or scaling up production, our solutions help you analyze pellet quality, optimize feedstock, and ensure efficiency.

Contact our experts today to discuss how KINTEK can support your biomass conversion and fuel pellet production goals.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy