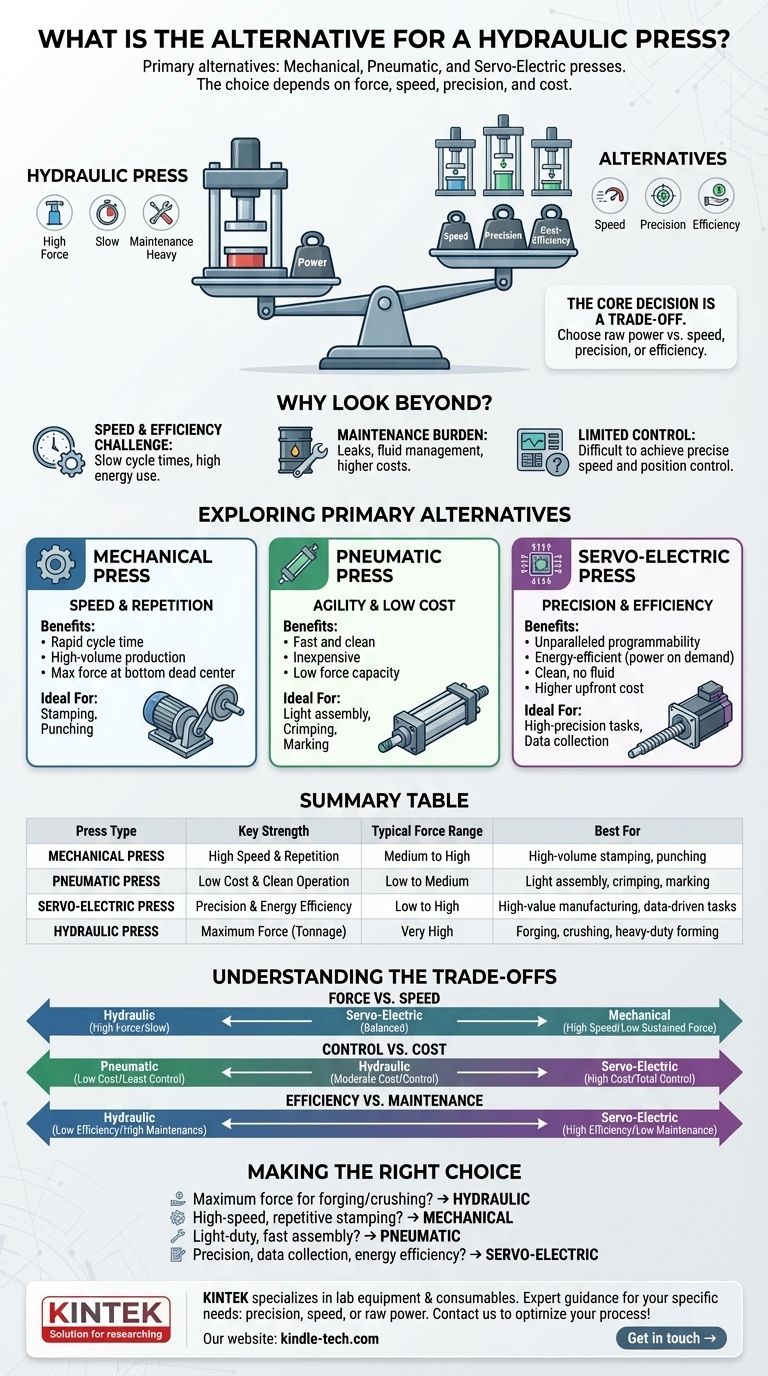

The primary alternatives to a hydraulic press are mechanical, pneumatic, and servo-electric presses. While hydraulic systems are renowned for generating immense force, they come with significant trade-offs in speed, efficiency, and maintenance. The best alternative depends entirely on the specific application's requirements for force, speed, precision, and operational cost.

The core decision is a trade-off. You must choose between the raw, high-tonnage power of a hydraulic press and the speed, precision, or cost-efficiency offered by mechanical, pneumatic, and servo-electric alternatives.

Why Look Beyond the Hydraulic Press?

A hydraulic press uses fluid pressure to generate force, making it ideal for high-tonnage applications like crushing cars or forging metal. However, its operational characteristics present several challenges that drive the need for alternatives.

The Challenge of Speed and Efficiency

Hydraulic presses are often slow. The time it takes for the hydraulic pump to build pressure and move the cylinder can limit production throughput. They also tend to have high energy consumption, as the pump must often run continuously to maintain pressure.

The Burden of Maintenance

These systems require significant upkeep. Hydraulic fluid can leak, creating safety hazards and a messy work environment, and some fluids are flammable. This potential for leakage and the need to manage fluid levels and quality contribute to higher maintenance costs.

The Need for Better Control

While powerful, traditional hydraulic presses offer limited control over the pressing operation. Achieving precise, repeatable control over speed and position throughout the stroke can be difficult, which is a critical requirement in modern manufacturing.

Exploring the Primary Alternatives

Each alternative press technology excels in different areas, directly addressing the weaknesses of a hydraulic system.

The Mechanical Press: Speed and Repetition

A mechanical press generates force through a motor-driven flywheel and a crank mechanism. This design is built for speed and is the backbone of high-volume stamping and punching operations.

Its key advantage is its rapid cycle time. However, it only delivers its maximum rated force at the very bottom of the stroke, making it less versatile for applications requiring sustained force.

The Pneumatic Press: Agility and Low Cost

A pneumatic press, or air press, uses compressed air to drive a cylinder. These presses are extremely fast, clean, and relatively inexpensive to purchase and operate.

They are ideal for light-duty applications like assembly, crimping, or marking where high force is not a requirement. Their main limitation is the lower force capacity and the difficulty of maintaining precise force control due to the compressibility of air.

The Servo-Electric Press: Precision and Efficiency

The servo-electric press is the most modern alternative. It uses a high-torque servomotor and a ball screw to precisely control the ram's position, speed, and force throughout the entire stroke.

This technology offers unparalleled programmability, is exceptionally energy-efficient (using power only on demand), and is very clean, with no risk of fluid leaks. While their upfront cost is higher and they typically don't reach the extreme tonnage of hydraulics, they are the superior choice for high-precision tasks.

Understanding the Trade-offs

Choosing the right press involves balancing four key factors: force, speed, control, and cost. No single technology is superior in all categories.

Force vs. Speed

A hydraulic press offers the highest force potential but generally operates at the slowest speeds. A mechanical press offers the highest speed for repetitive tasks, while a servo-electric press provides a strong balance of both high speed and controlled force.

Control vs. Cost

Pneumatic presses offer the lowest initial cost but the least control. Hydraulic presses offer moderate cost and control, while servo-electric presses provide total, programmable control at the highest initial investment.

Efficiency vs. Maintenance

Servo-electric presses are the most energy-efficient and have very low maintenance needs. In contrast, hydraulic presses are the least efficient and demand the most maintenance due to their fluid-based systems and potential for leaks.

Making the Right Choice for Your Application

Your final decision should be guided by the single most important requirement of your specific task.

- If your primary focus is maximum force for forging or crushing: A hydraulic press often remains the most cost-effective solution for ultra-high tonnage.

- If your primary focus is high-speed, repetitive stamping: A mechanical press is the unmatched industry standard for throughput and efficiency.

- If your primary focus is light-duty, fast assembly: A pneumatic press provides a simple, clean, and inexpensive solution.

- If your primary focus is precision, data collection, and energy efficiency: A servo-electric press is the modern choice for high-value manufacturing and assembly.

By clearly defining your application's core need, you can confidently select the press technology that will deliver the best performance and value for your operation.

Summary Table:

| Press Type | Key Strength | Typical Force Range | Best For |

|---|---|---|---|

| Mechanical Press | High Speed & Repetition | Medium to High | High-volume stamping, punching |

| Pneumatic Press | Low Cost & Clean Operation | Low to Medium | Light assembly, crimping, marking |

| Servo-Electric Press | Precision & Energy Efficiency | Low to High | High-value manufacturing, data-driven tasks |

| Hydraulic Press | Maximum Force (Tonnage) | Very High | Forging, crushing, heavy-duty forming |

Still unsure which press technology is right for your lab or production line?

KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the perfect press for your specific needs—whether you prioritize precision, speed, or raw power. Our team can help you optimize your process for efficiency and reliability.

Contact us today to discuss your application and get a personalized recommendation. Let's find the ideal solution together! Get in touch →

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Double Plate Heating Press Mold for Lab

- Heated Hydraulic Press Machine with Integrated Manual Heated Plates for Lab Use

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples