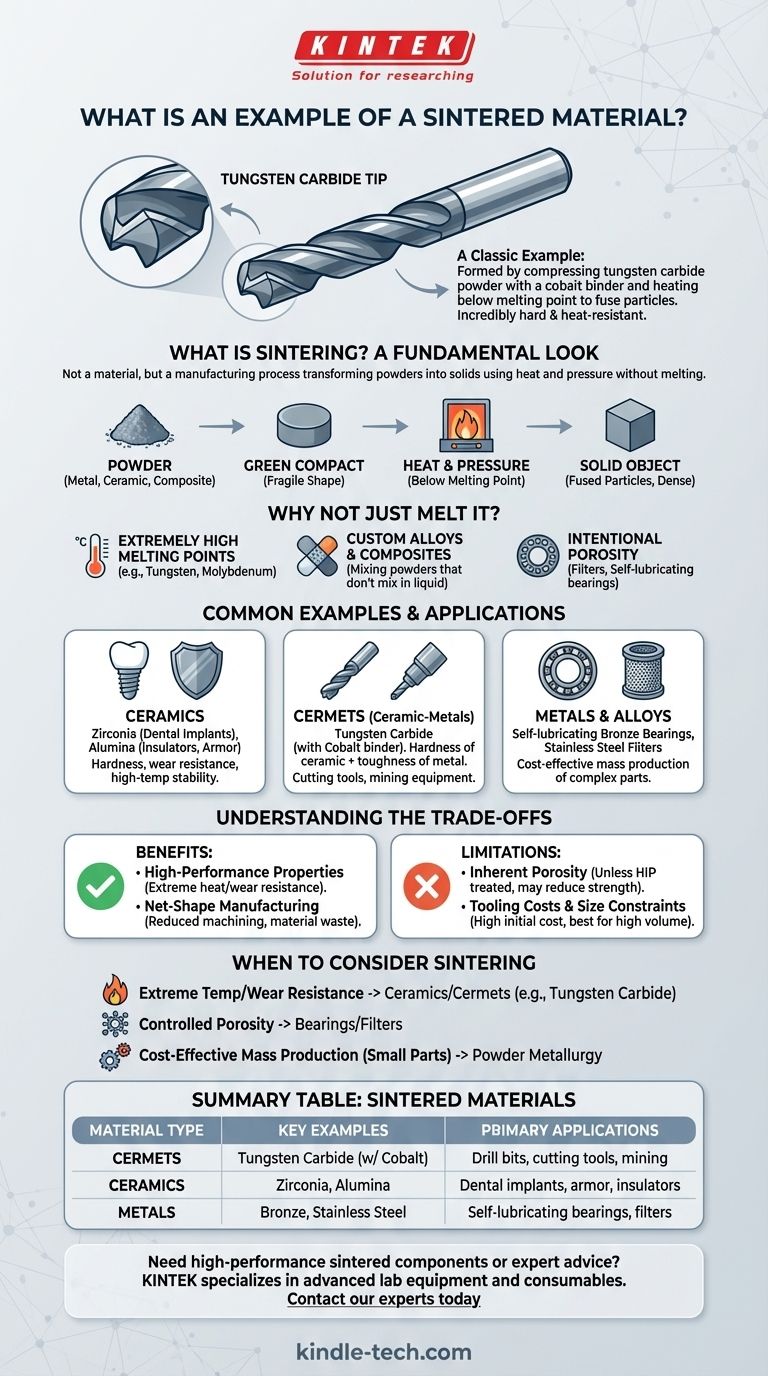

A classic example of a sintered material is the tungsten carbide tip found on drill bits and other cutting tools. This incredibly hard and heat-resistant material is not melted and cast like steel but is formed by compressing tungsten carbide powder with a binder like cobalt and heating it below its melting point until the particles fuse together.

Sintering is not a material, but a manufacturing process that transforms powders into a dense, solid mass using heat and pressure without melting the primary material. This method unlocks the ability to create high-performance components from materials, like ceramics and superalloys, that are difficult or impossible to shape through conventional melting and casting.

What is Sintering? A Fundamental Look

Sintering is a thermal treatment process for bonding powder particles into a coherent, solid object. It is a cornerstone of a field known as powder metallurgy.

The Core Principle: Powder to Solid

The process begins with a fine powder of the desired material, which can be a metal, ceramic, or a composite. This powder is compacted into a shape, often called a "green compact," which is fragile.

This compact is then heated in a controlled-atmosphere furnace to a temperature below the material's melting point. At this high temperature, atoms at the contact points of the powder particles diffuse across the boundaries, fusing the particles together and creating a single, solid piece.

Why Not Just Melt It?

Sintering is employed when melting is impractical or undesirable. It allows engineers to create materials with unique properties that cannot be achieved otherwise.

Key advantages include working with materials that have extremely high melting points (like tungsten or molybdenum) and creating custom alloys or composites by mixing powders that would not readily mix in a liquid state. It also allows for the intentional creation of porous materials, such as filters or self-lubricating bearings.

Common Examples of Sintered Materials & Applications

While the process is consistent, the applications are incredibly diverse, spanning far beyond just metallic powders.

Ceramics

Many advanced technical ceramics are produced via sintering. These materials are valued for their hardness, wear resistance, and stability at high temperatures.

Examples include zirconia used in dental implants and crowns, and alumina used for electrical insulators and ballistic armor plates.

Cermets (Ceramic-Metals)

Cermets are composites where ceramic and metallic materials are combined. The goal is to gain the hardness of the ceramic and the toughness of the metal.

The most prominent example is tungsten carbide, where hard carbide particles are held in a tough metallic binder (like cobalt). This is the standard for metal cutting tools, mining equipment, and wear-resistant parts.

Metals and Alloys

Sintering is widely used for mass-producing small, complex metal parts, as it can be more cost-effective than machining.

Common examples are self-lubricating bronze bearings, which are intentionally porous to hold oil, and stainless steel filters, which use controlled porosity to separate particles from fluids.

Understanding the Trade-offs of Sintering

Like any manufacturing process, sintering has distinct advantages and limitations that make it suitable for some applications but not others.

The Benefit: High-Performance Properties

Sintering is the go-to method for creating parts from materials with exceptionally high melting points. It allows for the production of components that can withstand extreme heat, wear, and corrosive environments.

The Benefit: Net-Shape Manufacturing

The process can produce parts very close to their final dimensions, known as "net-shape" or "near-net-shape" manufacturing. This drastically reduces or eliminates the need for costly secondary machining operations and minimizes material waste.

The Limitation: Inherent Porosity

Unless additional steps like hot isostatic pressing are used, most sintered parts will contain a small amount of residual porosity. While this can be an advantage for applications like filters, it can act as a stress concentration point, potentially reducing the material's ultimate strength compared to a fully dense, wrought equivalent.

The Limitation: Tooling Costs and Size Constraints

The initial cost for the dies and presses used to compact the powder can be high, making sintering most economical for high-volume production runs. Furthermore, producing very large or extremely complex components can be technically challenging and expensive.

When to Consider Sintering for a Project

Choosing a manufacturing process depends entirely on your material requirements, production volume, and cost targets.

- If your primary focus is extreme temperature and wear resistance: Sintering is the superior choice for creating parts from high-melting-point ceramics and cermets like tungsten carbide.

- If your primary focus is controlled porosity: Sintering is the only practical method for manufacturing components like self-lubricating bearings and metallic filters.

- If your primary focus is cost-effective mass production of small metal parts: Sintering (powder metallurgy) can offer significant cost savings over machining for high volumes of components like gears and cams.

Ultimately, sintering empowers engineers to create advanced materials and components that simply could not exist through traditional manufacturing methods.

Summary Table:

| Sintered Material Type | Key Examples | Primary Applications |

|---|---|---|

| Cermets | Tungsten Carbide (with Cobalt binder) | Drill bits, cutting tools, mining equipment |

| Ceramics | Zirconia, Alumina | Dental implants, armor plates, insulators |

| Metals | Bronze, Stainless Steel | Self-lubricating bearings, filters |

Need high-performance sintered components or expert advice on powder metallurgy? KINTEK specializes in advanced lab equipment and consumables for materials research and development. Our expertise can help you select the right materials and processes for your project, ensuring optimal performance and cost-efficiency. Contact our experts today to discuss how we can support your laboratory's sintering and materials science needs!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Warm Isostatic Press for Solid State Battery Research

People Also Ask

- How much force can a hydraulic press exert? Understanding its immense power and design limits.

- What is the role of a laboratory-grade heated hydraulic press in MEA fabrication? Optimize Fuel Cell Performance

- Why do you need to follow the safety procedure in using hydraulic tools? Prevent Catastrophic Failure and Injury

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing