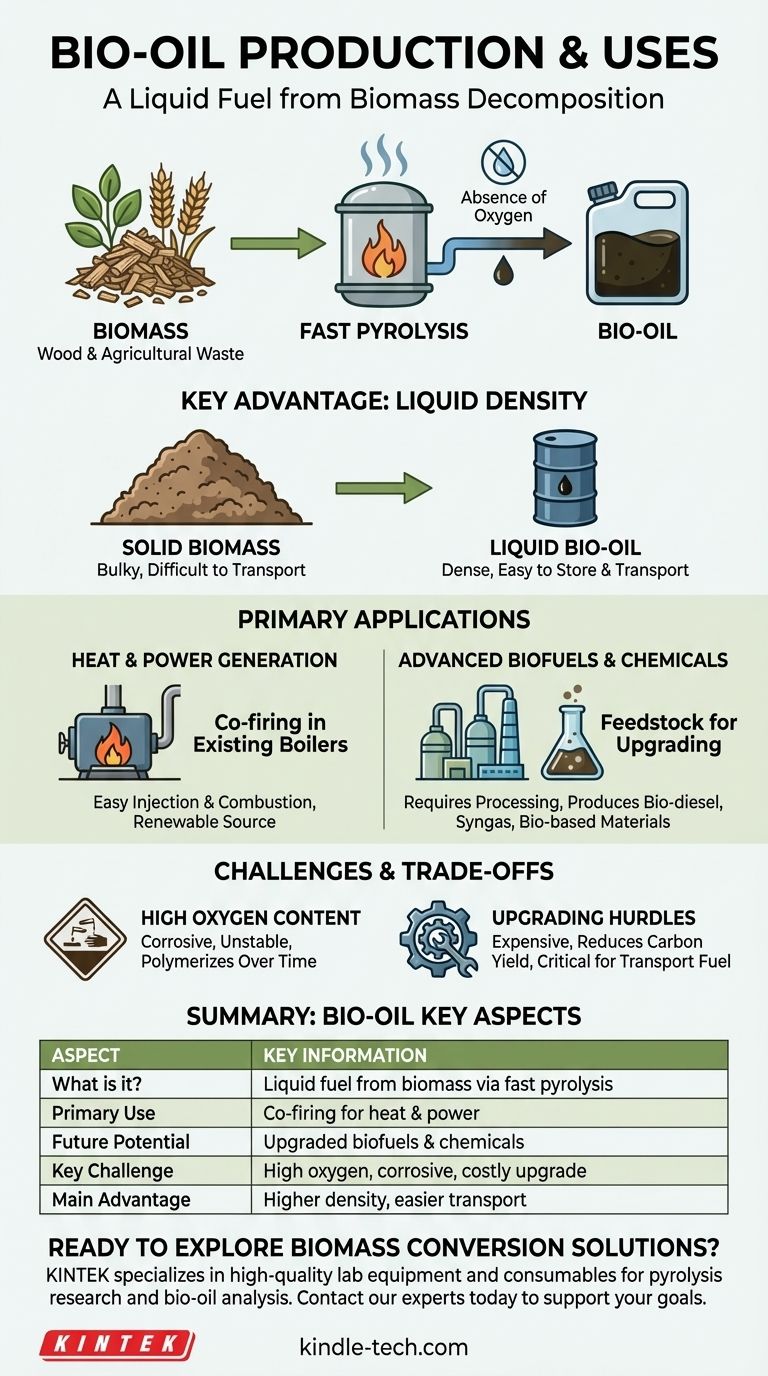

In essence, bio-oil is a liquid fuel produced from the thermal decomposition of biomass, such as wood or agricultural waste. Its primary uses are for generating heat and power, often by being co-fired in existing industrial boilers, and as a feedstock for producing advanced biofuels and valuable chemicals after significant processing.

Bio-oil offers a dense, transportable liquid alternative to solid biomass, but its raw form is corrosive and unstable. Its practical, near-term use is largely confined to industrial heating, while its potential as a transportation fuel depends on overcoming significant and costly upgrading challenges.

What is Bio-Oil and How is It Made?

Bio-oil, sometimes called pyrolysis oil, is the direct output of converting solid organic matter into a liquid. Understanding its basic properties is key to grasping its applications and limitations.

A Liquid Derivative of Biomass

Bio-oil is a dark, viscous liquid with a composition that mirrors the biomass it came from, including high water and oxygen content. It is typically produced through a process called fast pyrolysis, where biomass is rapidly heated in the absence of oxygen.

This process breaks down the complex polymers in wood or crop residues into smaller, liquid organic compounds. The result is a liquid that is much denser than the original biomass.

The Advantage of Liquid Density

A primary advantage of converting biomass to bio-oil is logistics. Because it is a liquid with a higher energy density than the raw, bulky biomass, it is significantly cheaper and easier to store and transport.

This liquid form allows it to be pumped and handled with existing infrastructure, which is a major benefit for use in large-scale industrial facilities like power stations.

Primary Applications of Bio-Oil

The applications for bio-oil fall into two main categories: direct use for energy and indirect use as a chemical feedstock. Its unique properties dictate where it can be applied effectively.

Heat and Power Generation

The most immediate and attractive use for bio-oil is in co-firing. This involves blending it with traditional fossil fuels, like coal or fuel oil, in existing power station boilers.

Its liquid nature makes it easy to inject and combust, allowing power companies to displace a portion of their fossil fuel consumption with a renewable source without massive equipment overhauls.

A Feedstock for Advanced Biofuels

Raw bio-oil is not suitable for direct use in standard engines due to its corrosiveness and instability. However, it can be "upgraded" through further chemical processing.

This upgrading can convert it into more stable fuels like bio-diesel, or it can be used to produce syngas, a building block for various synthetic fuels. It can also be refined into specialized fuels for modified engines.

A Source for Bio-based Chemicals

Beyond fuel, bio-oil is a rich mixture of valuable organic compounds. It can be seen as a form of "liquid wood" from which specialty chemicals, resins, and other bio-based materials can be extracted and refined.

Understanding the Trade-offs and Challenges

While promising, bio-oil is far from a perfect "drop-in" replacement for petroleum. Its chemical nature presents significant technical and economic hurdles that limit its widespread adoption.

The Problem of High Oxygen Content

The single greatest challenge is bio-oil's high organic oxygen content. This oxygen makes the oil acidic and corrosive, damaging to standard pipes, pumps, and engine components. It also contributes to its chemical instability, causing it to thicken and polymerize over time.

The Challenge of Upgrading

Because of its corrosiveness and instability, using bio-oil often requires either modifying existing equipment to handle it or subjecting the oil to an expensive upgrading process to remove the oxygen. This deoxygenation step is a critical barrier to its use as a mainstream transportation fuel.

The Yield vs. Quality Dilemma

Efforts to improve bio-oil quality by reducing its oxygen content present a difficult trade-off. While these processes make the oil more stable and easier to separate from its aqueous phase, they often reduce the overall yield of useful carbon, meaning less final product is recovered from the initial biomass.

Making the Right Choice for Your Goal

How you approach bio-oil depends entirely on your end goal, as its viability चीनs dramatically by application.

- If your primary focus is immediate industrial decarbonization: Leverage bio-oil for co-firing in boilers and furnaces, as this is its most mature and cost-effective application.

- If your primary focus is advanced transportation fuels: Treat bio-oil as a promising but challenging intermediate feedstock that requires significant investment in upgrading and refining technology.

- If your primary focus is green chemistry: View bio-oil as a complex but valuable source for extracting high-value, bio-based platform chemicals.

Ultimately, bio-oil's value lies in its potential to bridge the gap between solid, low-density biomass and the liquid fuel infrastructure our world depends on.

Summary Table:

| Aspect | Key Information |

|---|---|

| What is it? | A dark, viscous liquid fuel produced from biomass via fast pyrolysis. |

| Primary Use | Co-firing in industrial boilers for heat and power generation. |

| Future Potential | Feedstock for upgraded biofuels (e.g., biodiesel) and bio-based chemicals. |

| Key Challenge | High oxygen content makes it corrosive, unstable, and costly to upgrade. |

| Main Advantage | Higher energy density than solid biomass, enabling easier transport and storage. |

Ready to explore biomass conversion solutions for your laboratory or pilot plant?

KINTEK specializes in high-quality lab equipment and consumables for pyrolysis research and bio-oil analysis. Whether you're developing new catalysts, optimizing yields, or characterizing bio-oil properties, our reliable tools can help you overcome technical challenges and advance your renewable energy projects.

Contact our experts today to discuss how we can support your bio-oil research and development goals.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Single Horizontal Jar Mill

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Automatic Laboratory Heat Press Machine

- Vacuum Induction Melting Spinning System Arc Melting Furnace

People Also Ask

- Can sintered parts be machined? How to Overcome the Challenges of Porosity

- What are the 3 types of heat transfer? Master Conduction, Convection & Radiation for Your Lab

- Why is flux important when brazing? It Removes the Invisible Barrier for a Perfect Bond

- What is the key difference between calcination and sintering? Understanding Purification vs. Consolidation

- What are the basics of an electric arc furnace? A Guide to Efficient Metal Recycling

- Which institutions have adjusted their ULT freezer set points to -70°C? Save Energy Without Risking Samples

- What is the difference between batch and continuous reactor for pyrolysis? Choose the Right System for Your Needs

- What are the applications of synthetic diamonds? From Cutting Tools to Quantum Computers