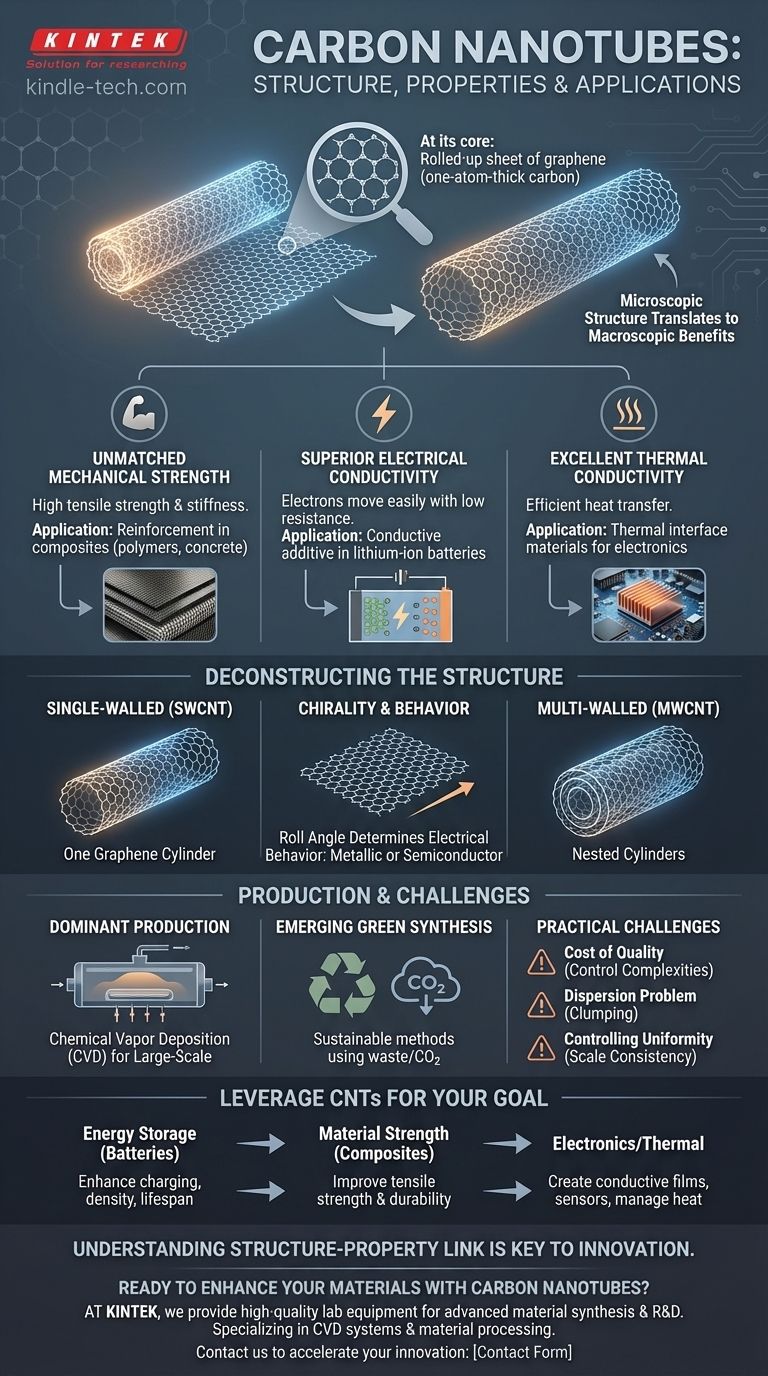

At its core, a carbon nanotube is a rolled-up sheet of graphene, which is a single, one-atom-thick layer of carbon atoms arranged in a hexagonal lattice. This unique cylindrical structure gives rise to its extraordinary properties: exceptional mechanical strength, high electrical conductivity, and efficient thermal conductivity.

The true value of carbon nanotubes lies in how their microscopic, cylindrical structure directly translates into macroscopic benefits, making them a powerful additive for enhancing the performance of materials ranging from batteries to concrete.

Deconstructing the Carbon Nanotube Structure

To understand the properties of carbon nanotubes (CNTs), we must first understand their fundamental architecture. It all begins with a material called graphene.

The Graphene Foundation

A carbon nanotube is best visualized as a seamless cylinder formed by rolling up a sheet of graphene. This honeycomb-like lattice of carbon atoms is incredibly strong, and this inherent strength is passed directly to the nanotube.

Single-Walled vs. Multi-Walled Structures

There are two primary types of carbon nanotubes. Single-walled carbon nanotubes (SWCNTs) consist of a single graphene cylinder, while multi-walled carbon nanotubes (MWCNTs) are made of several concentric cylinders nested inside one another. This structural difference impacts their properties, cost, and suitability for various applications.

The Critical Role of Chirality

The angle at which the graphene sheet is "rolled" to form the tube is known as its chirality. This geometric detail is critically important because it determines the nanotube's electrical behavior, making it act either as a metallic conductor or a semiconductor.

The Extraordinary Properties of Carbon Nanotubes

The unique structure of CNTs gives them a combination of properties not found in any other material.

Unmatched Mechanical Strength

Carbon nanotubes are among the strongest and stiffest materials ever discovered in terms of tensile strength. This makes them a highly sought-after reinforcement agent in composite materials, such as conductive polymers and fiber-reinforced composites.

Superior Electrical Conductivity

Due to their structure, electrons can move easily along the length of a nanotube with little resistance. This high conductivity is why their primary commercial use is as a conductive additive in lithium-ion batteries, significantly improving electrode performance.

Excellent Thermal Conductivity

CNTs are also excellent thermal conductors, efficiently transferring heat. This property makes them valuable for applications like thermal interface materials, which help dissipate heat in electronics and other high-performance systems.

Production and Key Applications

While the properties are remarkable, their practical use depends on scalable production and integration into real-world products.

Dominant Production Methods

Older methods for creating CNTs include laser ablation and arc discharge. However, Chemical Vapor Deposition (CVD) is the dominant commercial process used today for large-scale production.

Emerging Green Synthesis

Newer, more sustainable methods are being developed. These include using waste feedstocks or converting captured carbon dioxide into CNTs through electrolysis, aligning with the growing demand for green technologies.

Major Industrial Uses

Beyond their primary role in batteries, CNTs are being used to enhance a wide range of materials. They are added to concrete and asphalt to improve strength, integrated into polymers to create conductive plastics, and used in transparent conductive films for displays and sensors.

Understanding the Practical Challenges

Despite their potential, working with carbon nanotubes involves significant technical hurdles that must be managed.

The Cost of Quality

The synthesis of high-quality, uniform CNTs can be expensive and complex. Controlling parameters like temperature, carbon source, and residence time is crucial but adds to the cost and engineering effort.

The Dispersion Problem

Carbon nanotubes have a strong tendency to clump together, which can prevent them from being evenly distributed within a host material like a polymer or liquid. Achieving good dispersion is a critical step to unlocking their reinforcing properties.

Controlling for Uniformity

Producing CNTs with a consistent diameter, length, and chirality at an industrial scale remains a major challenge. This lack of uniformity can lead to variable performance in the final product.

How to Leverage CNTs for Your Goal

The right application for CNTs depends entirely on which of their unique properties you need to harness.

- If your primary focus is energy storage: Use CNTs as a conductive additive in battery electrodes to enhance charging rates, increase energy density, and extend the battery's operational lifespan.

- If your primary focus is material strength: Incorporate CNTs as a reinforcing agent into composites like polymers, concrete, or metals to dramatically improve tensile strength and durability.

- If your primary focus is electronics or thermal management: Explore CNTs for creating transparent conductive films, high-performance sensors, or advanced thermal interface materials to manage heat in compact systems.

Ultimately, understanding the direct link between the nanotube's structure and its properties is the key to innovating and solving challenges across countless industries.

Summary Table:

| Property | Description | Key Application |

|---|---|---|

| Mechanical Strength | Among the strongest materials known; high tensile strength. | Reinforcement in composites (polymers, concrete). |

| Electrical Conductivity | Electrons flow with minimal resistance along the tube. | Conductive additive in lithium-ion battery electrodes. |

| Thermal Conductivity | Efficient heat transfer along the nanotube axis. | Thermal interface materials for electronics cooling. |

| Structure Types | SWCNTs (single cylinder) and MWCNTs (nested cylinders). | Tailored for specific electrical or mechanical needs. |

Ready to enhance your materials with carbon nanotubes?

At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored for advanced material synthesis and R&D. Whether you're developing next-generation batteries, stronger composites, or efficient thermal management systems, our expertise in chemical vapor deposition (CVD) systems and material processing can help you achieve superior results.

Contact us today to discuss how our solutions can accelerate your innovation with carbon nanotubes!

Visual Guide

Related Products

- Large Vertical Graphite Vacuum Graphitization Furnace

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Hexagonal Boron Nitride HBN Ceramic Ring

- Laboratory Hybrid Tissue Grinding Mill

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- Why carbon nanotubes are better than graphene? Matching Material Geometry to Your Engineering Challenge

- What are the methods of deposition of ITO? A Guide to Choosing the Right Technique

- What is the cheapest way to produce graphene? Balance Cost, Quality, and Scale for Your Needs

- How were the first gem-quality synthetic diamonds produced? Discover the 1970 GE Breakthrough

- What are the different types of exfoliation for graphene? Choose the Right Method for Your Application

- What are the methods of carbon nanotubes fabrication? From Arc Discharge to Scalable CVD

- What are the applications of optical coating? Unlock Advanced Light Control for Your Industry

- What are optical coatings made of? Metals, Dielectrics & Polymers for Light Control