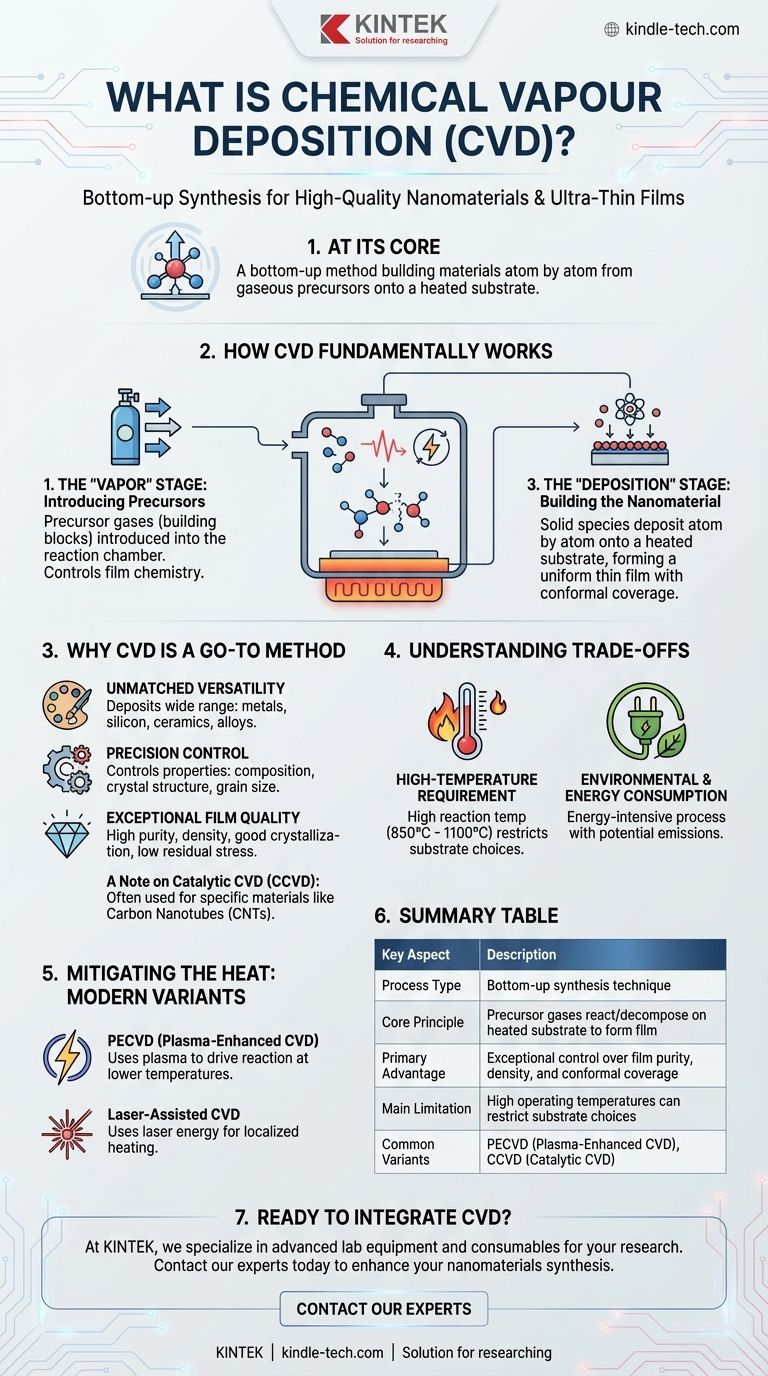

At its core, Chemical Vapor Deposition (CVD) is a method for building high-quality, ultra-thin films and nanomaterials from the ground up. It works by introducing reactive gases (precursors) into a chamber, where they undergo a chemical reaction or decompose on a heated surface, known as a substrate. The solid products of this reaction then deposit onto the substrate, forming the desired nanomaterial layer by layer.

CVD is a powerful and versatile "bottom-up" synthesis technique that offers exceptional control over a material's final properties. However, its effectiveness is often balanced against its primary limitation: a high operating temperature that can restrict the choice of substrate materials.

How CVD Fundamentally Works

To understand its utility, it's helpful to break the process down into its three essential stages: vapor, chemical reaction, and deposition.

The "Vapor" Stage: Introducing Precursors

The process begins by feeding specific precursor gases into a reaction chamber. These gases are the building blocks of the final material and are supplied from an external source.

The composition and flow rate of these gases are the first critical parameters that control the final film's chemistry.

The "Chemical" Stage: Triggering the Reaction

Inside the chamber, energy is applied—most commonly in the form of heat. This energy causes the precursor gases to become unstable and either react with each other or decompose.

This chemical change transforms the gaseous precursors into new, solid species and various byproducts, which remain in a gaseous state.

The "Deposition" Stage: Building the Nanomaterial

The newly formed solid species then deposit onto a heated substrate placed inside the chamber. This deposition builds the material atom by atom or molecule by molecule, resulting in a highly uniform and dense thin film.

Because the deposition occurs from a gas phase, the process can coat complex, three-dimensional shapes with exceptional uniformity, a property known as conformal coverage.

Why CVD is a Go-To Method for Nanomaterials

CVD is one of the most widely used techniques for nanomaterial synthesis because of the significant advantages it offers in control and quality.

Unmatched Material Versatility

CVD is not limited to one class of material. It can be used to deposit a vast range of materials, including metal films, non-metal films like silicon dioxide, multi-component alloys, and complex ceramic compounds.

Precision Control Over Structure

By carefully adjusting process parameters like temperature, pressure, and gas flow rates, operators can precisely control the final material's properties. This includes its chemical composition, crystal structure, grain size, and morphology.

Exceptional Film Quality

The films produced by CVD are known for their high purity and density. The process results in materials with good crystallization and low residual stress, which are critical for high-performance applications like solar cells (polysilicon) and electronics.

A Note on Catalytic CVD (CCVD)

For specific materials like carbon nanotubes (CNTs), a catalyst is often used on the substrate. This variation, Catalytic CVD (CCVD), is a mainstream method because it enhances structural control and cost-effectiveness.

Understanding the Trade-offs and Limitations

No technique is without its drawbacks. An objective assessment of CVD requires understanding its primary challenges.

The High-Temperature Requirement

The most significant limitation of traditional CVD is its high reaction temperature, often between 850°C and 1100°C. Many substrate materials, such as polymers or certain metals, cannot withstand this heat without melting or degrading.

Mitigating the Heat: Modern CVD Variants

To overcome this limitation, several lower-temperature CVD methods have been developed. Techniques like Plasma-Enhanced CVD (PECVD) or Laser-Assisted CVD use alternative energy sources to drive the chemical reaction, allowing for deposition at much lower temperatures.

Environmental and Energy Consumption

The synthesis process, particularly the high heat required, is energy-intensive. This can lead to significant energy consumption and greenhouse gas emissions, impacting the life cycle ecotoxicity and overall cost-effectiveness of the material produced.

Applying This to Your Project

Your choice to use CVD should be based on a clear understanding of your project's priorities and constraints.

- If your primary focus is high-purity, crystalline films on a durable substrate: Conventional CVD is an excellent choice, offering unparalleled control over material quality.

- If your primary focus is coating a temperature-sensitive material: Standard CVD is not viable; you must investigate lower-temperature variants like PECVD.

- If your primary focus is cost-effective mass production: You must carefully analyze the energy consumption, precursor material costs, and potential need for catalysts to determine the overall economic feasibility.

Ultimately, CVD is a powerful tool for creating high-performance nanomaterials when its principles and trade-offs are fully understood.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Bottom-up synthesis technique |

| Core Principle | Precursor gases react/decompose on a heated substrate to form a solid film |

| Primary Advantage | Exceptional control over film purity, density, and conformal coverage |

| Main Limitation | High operating temperatures can restrict substrate choices |

| Common Variants | PECVD (Plasma-Enhanced CVD), CCVD (Catalytic CVD) for lower temperatures or specific materials like CNTs |

Ready to integrate precise, high-quality nanomaterial synthesis into your lab?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your research needs. Whether you're exploring CVD for high-purity films or require solutions for temperature-sensitive substrates, our expertise can help you achieve superior results.

Contact our experts today to discuss how our solutions can enhance your nanomaterials synthesis and drive your projects forward.

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What role does Chemical Vapor Deposition (CVD) equipment play in the preparation of C/C composites? Expert Analysis

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- Why are carbon nanotubes important in industry? Unlocking Next-Generation Material Performance