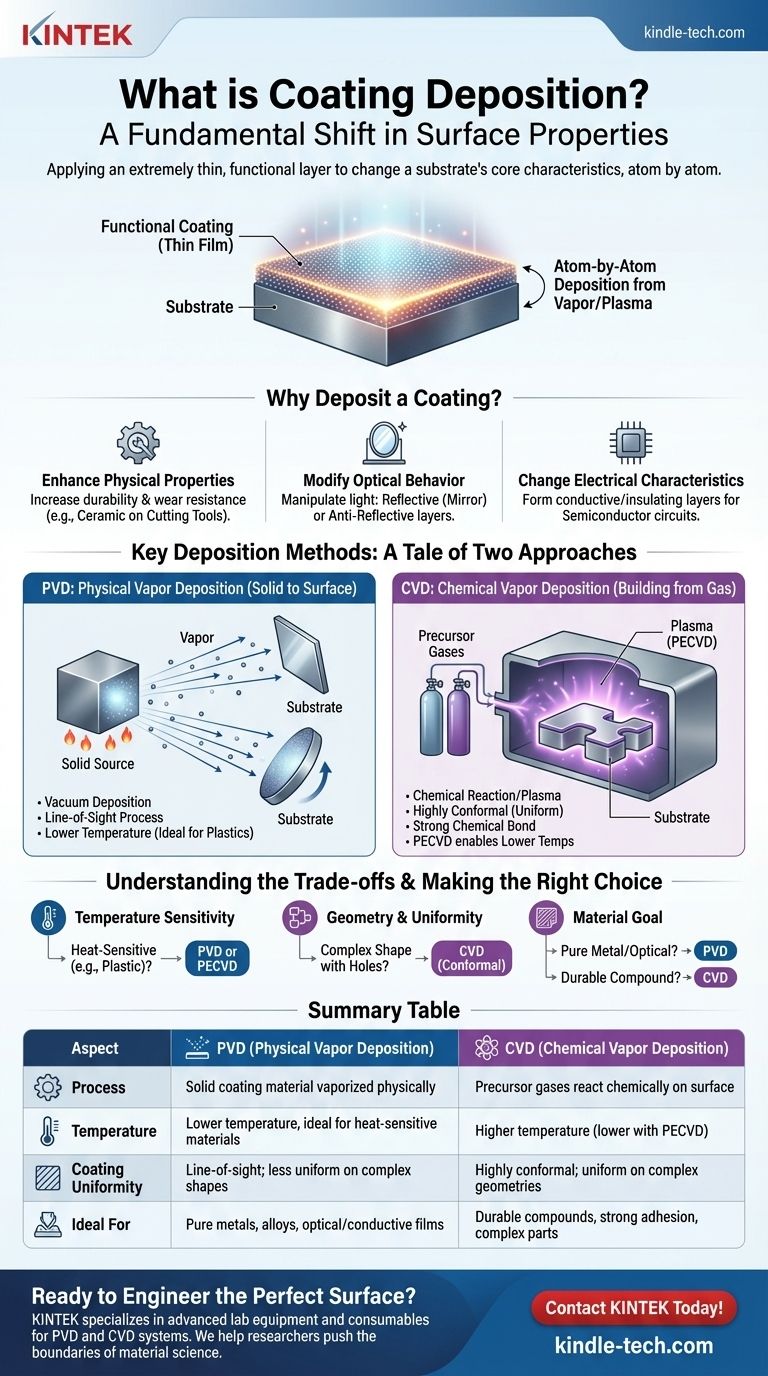

In essence, coating deposition is a family of processes used to apply an extremely thin, functional layer of material onto the surface of an object, known as a substrate. The goal is not merely to cover the object, but to fundamentally change its surface properties—making it harder, more reflective, or more resistant to corrosion. This is accomplished by transforming a coating material into a vapor or plasma and then allowing it to condense or react onto the substrate's surface atom by atom.

Coating deposition is not a single technique, but a set of advanced manufacturing tools. The core challenge is selecting the right process—based on principles fatores like temperature, pressure, and chemistry—to achieve a specific functional property on a specific material.

The Fundamental Goal: Why Deposit a Coating?

The primary driver for using deposition is to grant a bulk material surface properties it doesn't naturally possess. This creates a final product that has the ideal core characteristics (like the strength of steel or the low cost of plastic) combined with ideal surface characteristics.

Enhancing Physical Properties

Coatings can drastically increase a component's durability. Thin layers of ceramic materials, for example, are deposited onto metal cutting tools to make them incredibly hard and wear-resistant, extending their operational life.

Modifying Optical Behavior

Many optical components rely on deposition. A mirror is created by depositing a thin, highly reflective layer of metal, like aluminum, onto a glass substrate. Conversely, anti-reflective coatings are carefully layered to manipulate light waves and maximize transmission.

Changing Electrical Characteristics

Deposition is fundamental to the entire semiconductor industry. It is used to lay down the ultra-thin layers of conductive, semi-conductive, and insulating materials that form the microscopic circuits inside a computer chip.

Key Deposition Methods: A Tale of Two Approaches

While there are dozens of specific techniques, they generally fall into two major categories: Physical Vapor Deposition and Chemical Vapor Deposition. The methods described in the references highlight the core differences between these two families.

Physical Vapor Deposition (PVD): From Solid to Surface

PVD processes take a solid coating material, turn it into a vapor using physical means, and transport that vapor onto the substrate.

The vacuum deposition method is a classic example of PVD. A solid metal is heated in a high-vacuum chamber until it evaporates. This metal vapor then travels in a straight line and condenses as a thin film on the cooler components, like the way steam fogs a cold mirror.

The vacuum is critical. It prevents the metal vapor from reacting with air and allows the evaporation to occur at a much lower temperature, making it possible to coat heat-sensitive materials like plastics.

Chemical Vapor Deposition (CVD): Building from Gas

CVD processes use precursor gases that flow over a substrate. A chemical reaction is then triggered on the substrate's surface, causing the gases to decompose and form a solid film.

Plasma deposition, often called Plasma-Enhanced CVD (PECVD), is an advanced form of this. Instead of relying solely on high heat to drive the reaction, it uses an electrical field to superheat the gas into a plasma.

This highly energetic plasma state allows the chemical reactions to occur at significantly lower temperatures, expanding the range of materials that can be coated while still creating a strong, chemically-bonded layer.

Understanding the Trade-offs

Choosing between PVD and CVD is a matter of balancing the requirements of the substrate, the desired coating properties, and the complexity of the part's geometry.

Temperature and Substrate Compatibility

PVD is generally a lower-temperature process, making it ideal for substrates that cannot withstand high heat, such as polymers and certain alloys. While traditional CVD requires very high temperatures, the use of plasma (PECVD) bridges this gap, enabling chemical deposition on more sensitive materials.

Coating Adhesion and Uniformity

CVD coatings are chemically reacted onto the surface, which can result in exceptional adhesion. The precursor gases can also flow into and around complex shapes, producing a highly conformal coating that is uniform everywhere.

PVD is a "line-of-sight" process. The vapor travels in a straight path from the source to the substrate. This makes it challenging to evenly coat complex, three-dimensional shapes with hidden surfaces, which is why parts are often rotated during the process.

Process and Material Control

PVD offers excellent control for depositing pure metals and alloys, making it perfect for optical and decorative applications like mirrors or a fireman's gold-tinted visor. CVD excels at creating highly durable, chemically distinct compounds like silicon nitride or diamond-like carbon.

Making the Right Choice for Your Goal

The best deposition method is entirely dependent on your end goal. The material of your part, its shape, and the function you need the surface to perform will dictate the correct technical path.

- If your primary focus is coating heat-sensitive materials like plastic: PVD or Plasma-Enhanced CVD (PECVD) are your best options due to their lower process temperatures.

- If your primary focus is achieving a highly uniform coating on a complex part with holes or undercuts: A CVD-based process is often superior due to the non-line-of-sight nature of precursor gases.

- If your primary focus is creating a pure metallic film for optical or conductive purposes: PVD processes like vacuum evaporation or sputtering are direct and highly effective.

Understanding these fundamental differences is the first step toward engineering the perfect surface for your application.

Summary Table:

| Aspect | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process | Solid coating material vaporized physically | Precursor gases react chemically on surface |

| Temperature | Lower temperature, ideal for heat-sensitive materials | Higher temperature (lower with PECVD) |

| Coating Uniformity | Line-of-sight; less uniform on complex shapes | Highly conformal; uniform on complex geometries |

| Ideal For | Pure metals, alloys, optical/conductive films | Durable compounds, strong adhesion, complex parts |

Ready to Engineer the Perfect Surface for Your Application?

Choosing the right coating deposition method is critical to achieving the surface properties your project demands. Whether you need to enhance durability with a hard ceramic coating, modify optical behavior for a lens, or deposit precise electrical layers for a semiconductor, the correct equipment is paramount.

KINTEK specializes in advanced lab equipment and consumables for coating deposition processes, including PVD and CVD systems. Our expertise helps researchers and manufacturers in industries from aerospace to electronics achieve superior results. We provide the reliable, high-performance tools you need to push the boundaries of material science.

Contact us today to discuss your specific coating challenges and discover how KINTEK's solutions can bring value to your laboratory — Get in touch now!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- How thick is sputtering gold? Achieve Angstrom-Level Precision for Your Application

- Which gas is used for plasma in sputtering? The Strategic Guide to Argon and Beyond

- What is the sintering temperature of polymers? Find Your Material's Perfect Sintering Window

- Which types of institutions or facilities typically require ULT freezers? Essential for Medical, Research, and Pharma Labs

- How does multizone heating work? Achieve Custom Comfort and Energy Savings

- What is the physical Vapour deposition method? A Guide to High-Performance Thin Films

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- How do you clean a sputtering chamber? Master the Critical Protocol for Purity and Yield